KEY POINTS

FireFly is rapidly laying the foundations for an upscaled production restart at Green Bay, with environmental approvals now secured, construction permitting underway and metallurgical tests returning outstanding results

Economic studies are well underway; The first of these will be a Scoping Study1 expected to be released in the March quarter of 2026

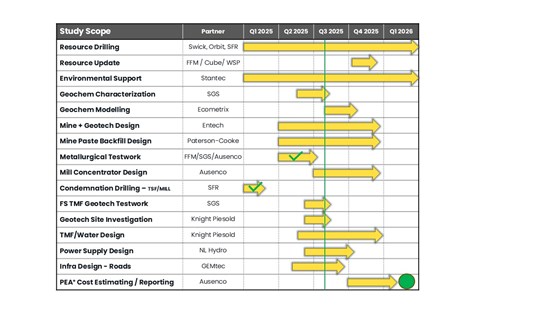

Other studies underway include mine design and scheduling, geotechnical, power analysis and tailings design

Surface sterilisation and geotechnical drilling has been completed at the site of the potential upscaled processing plant and tailings facility

Metallurgical Results:

Comprehensive metallurgical testing has been completed on bulk samples of mineralisation from the Ming Mine at Green Bay; The tests involved 1.5t of material and took place at the SGS metallurgical facility in Lakefield, Ontario

The results show that the Ming mineralisation is metallurgically simple and amenable to conventional low-cost processing; This includes exceptional results returned in tests on crushing, grinding, flotation, leaching and overall recovery

Copper recovery exceeded 98% and gold recovery exceeded 85%

Gold recovery is important because there is 550koz of contained gold in the current Mineral Resource Estimate (see Appendix B and ASX announcement dated 29 October 2024 for further details)

Testwork was conducted on both styles of mineralisation at the Ming Mine: the high-grade copper-gold VMS and the broad copper-stringer Footwall Zone

The results will be used to refine process design and cost/revenue models in the upcoming economic studies

FireFly remains well-funded, having strengthened its balance sheet as a result of substantially completing a multi-tranche capital raising2 (see ASX announcements dated 5, 10 and 16 June 2025) and share purchase plan (see ASX announcement dated 11 July 2025)

Cash, receivables and liquid investments as at 30 June 2025, proceeds from the Share Purchase Plan completed in July 2025, and anticipated net proceeds from the final remaining aspect of the equity raising, being the second tranche of the Institutional Placement, total A$1453 million

FireFly Managing Director Steve Parsons said: "We are making rapid progress on all fronts at Green Bay, with environmental approvals in place, economic studies underway and eight rigs drilling as part of the plan to keep growing and upgrading the Mineral Resource.

"And now these outstanding metallurgical results mean we have ticked another very important box along the path to fully unlocking the value of this exceptional asset.

"Not only did we achieve extremely high recovery rates, but we did it using simple, low-cost processing routes. This augurs very well for the project's overall capital and operating costs.

"These results will form part of the economic studies which we are now progressing in parallel with the drilling program ahead of the next Mineral Resource Estimate update.

"The results of all these work streams will come together to demonstrate why we believe Green Bay is so well-placed as a world-scale copper-gold project in a tier-one location".

West Perth, Western Australia--(Newsfile Corp. - August 4, 2025) - FireFly Metals Ltd (ASX: FFM) (TSX: FFM) (Company or FireFly) is pleased to announce that it has passed key milestones on the path to an upscaled production restart at its Green Bay project in Canada.

The Company has secured environmental approval for the processing plant, construction permitting has commenced and metallurgical tests have returned extremely strong results.

The metallurgical testwork is a key component of economic studies now underway, which will be incorporated into the Scoping Study due for completion in the March quarter of 2026.

The comprehensive metallurgical testwork was completed on 1,500kg of samples from the Ming Mine by SGS Canada Inc. (SGS) with supervision and technical support from Ausenco Engineering Canada ULC (Ausenco).

There are two distinct styles of mineralisation at the Ming underground mine at Green Bay. One comprises the upper copper-gold rich Volcanogenic Massive Sulphide (VMS) lenses. This sits above a broad copper stringer zone known as the Footwall Zone (FWZ).

The bulk samples for metallurgical testing incorporated representative samples of both VMS and FWZ. Work was also completed on numerous blend ratios for incorporation into mine scheduling in the economic studies.

Using an optimised flow sheet, metal recoveries to final copper concentrate from all samples averaged +98% Copper, +75% Gold and +78% Silver. Recent gravity and conventional leach testing of the pyrite flotation tails has achieved further improvements in precious metals recovery, with gold increasing to +85% and +84% for silver.

The improved recovery of gold enhances the economics of the upscaled restart, with the current Mineral Resource Estimate containing a total of 550koz of gold4 across all Mineral Resource categories, making it a significant contributor to potential future cash flow.

These results are a significant improvement in comparison to recoveries attained through the small-scale 500ktpa Nugget Pond processing plant, which recovered 95% of the copper but just 66% of the gold and 72% of the silver.

Testwork on the crushing and grinding of Ming ore demonstrated characteristics that point to low-cost mineral processing. The modest Bond Work Index Results (10.4-11.4kWh/t) indicates relatively low power consumption to crush and grind the primary ore. The low Abrasive Index results (0.1g-0.18g) suggest wear rates on milling components, such as grinding media and liners, will be relatively low, leading to lower maintenance and consumable costs.

For further information on the metallurgical test results, please refer to Appendix A 'Metallurgical Testwork Summary'. For details of drilling used for metallurgical testing, please refer to Appendix C.

Approval and Study Update

Permitting and economic studies on the upscaled restart of production at the Green Bay Project are well underway.

The Company is planning a staged resumption of mining operations at Green Bay with the construction of a new processing facility at the mine. The Company has received a conditional release from further detailed environmental and socio-economic assessment by the Province of Newfoundland and Labrador for an initial upscaled restart mining operation involving a plant with a throughput capacity of up to 1.8Mtpa (Environmental Release). Investors are cautioned that the plant capacity is a technical specification forming part of the environmental submission and not a forecast of the estimated production of the mining operation. The mining operation's forecast production will not be estimated until such time as the Company has prepared and announced its Scoping Study. Should a larger scale case be adopted than contemplated by the Environmental Release, further assessment will be required by government agencies.

Applications for construction permits are in progress, with early seasonal site preparation works scheduled for late 2025.

Key consultants have been engaged to complete economic evaluations of Green Bay, with the Company on track to complete a Scoping Study in Q1 2026.

Mining option studies have been conducted by Entech Mining consultants (Entech) based on the current MRE that incorporate all Mineral Resource categories. The review concluded that Transverse Long Hole Open Stoping (TLHOS) was the most suitable mining method for the broad FWZ. Conventional Long Hole Open Stoping (LHOS) was considered most suitable for the high-grade copper-gold VMS zones. TLHOS is a bulk mining method that extracts ore in panels perpendicular to the strike, offering production flexibility and selectivity whilst maintain large scales of production.

The mining methods selected require backfill to ensure total extraction of mineralisation zones. The Company has engaged leading specialist consulting firm Paterson & Cooke to design a paste fill system, which has the added environmental benefit of encapsulating +50% of tailings generated underground.

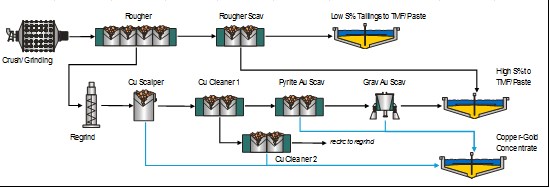

Ausenco has continued to assess options for processing, with the metallurgical testwork in this announcement used to optimise process flow. Advanced design work is underway. The current design incorporates a simple crush and grind utilising a semi-autogenous grind (SAG) and ball mill followed by conventional flotation.

Knight Piesold has completed trade off studies and preliminary designs for a surface Tailings Storage Facility (TSF). The final design will be completed in the coming months.

FireFly has completed sterilisation and geotechnical drilling in the areas proposed for the TSF and processing plant to be constructed at the mine. The drilling did not intersect mineralisation, and the geotechnical properties of the rock mass are favourable.

Power supply studies completed in conjunction with Newfoundland and Labrador Hydro (NL Hydro) remain ongoing and are expected to be completed in Q4 2025. High voltage power lines run through the Green Bay property, and NL Hydro have indicated there is sufficient capacity to supply the upscaled needs of the project.

Initial discussions regarding the shared construction of a concentrate export berth at the nearby Pine Cove deep water port are underway with local company Shoreline Aggregates (Shoreline). Final details will be provided in the economic studies.

Additionally, ongoing environmental monitoring and closure planning is underway, with Stantec Consultants supporting FireFly on achieving conditions of the Environmental Release.

A timeline of key study works is presented in Figure 1. The Company will report any material changes as the economic studies progress.

Figure 1: Timeline of key study work streams with the first economic study (Scoping Study) scheduled for completion in Q1 2026. In parallel with the study work, regional discovery drilling will remain ongoing throughout 2025-2026 with 2 surface rigs targeting new copper-gold discoveries within in easy trucking distance to the proposed processing plant. All timeframes are indicative and may be subject to change.

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/11430/261240_dd24358504936b91_003full.jpg

Forward Work Plan

Forward work at the Green Bay project continues to focus on the concurrent strategy of expanding the Mineral Resource, discovering new deposits and resuming copper production at a much larger scale than historical mining.

Underground resource drilling at the Ming Mine remains a key focus, with six drill rigs continuing at site for the foreseeable future. The focus remains split between increasing the confidence of the current MRE by infill drilling (4 rigs) and stepping out the known mineralisation at Ming beyond the extent of completed drilling (2 rigs).

The current infill drilling program will add significant value because only the Mineral Resources classified in the higher confidence Measured and Indicated (M&I) categories can be included future feasibility studies and in the calculation of ore reserves that will demonstrate economic viability of the project. It will also assist the Company as it considers various financing options, including potential offtake partnerships.

A MRE update is planned for Q4 20255. This estimate will be used to underpin the economic studies, including the Scoping Study scheduled for completion in Q1 20264. The quantity of infill drilling completed in 2025 is expected to result in a significant increase in the M&I Mineral Resource, which currently makes up 34% of the total MRE (see Appendix B for further information on the MRE).

The Company's longer-term growth strategy revolves around unlocking the potential of the entire mineral district. FireFly has assembled 346km2 of exploration claims that cover prospective mafic and felsic rocks.

Regional geophysics has recently identified a significant number of conductive anomalies in the same orientation as the Ming deposit (see ASX announcement dated 24 July 2025). Additionally, the Company's tenure hosts eight historical mining operations that have undergone limited exploration over the past 30 years. Systematic testing of the geophysical anomalies and down-plunge extents of the historical mines is ongoing, with two diamond rigs currently on surface.

The Company remains well funded to complete its growth and exploration strategy and has recently substantially completed a multi-tranche capital raising and Share Purchase Plan.6

Cash, receivables and liquid investments as at 30 June 2025, proceeds from the Share Purchase Plan completed in July 2025, and anticipated net proceeds from the final remaining aspect of the equity raising, being the second tranche of the Institutional Placement, total A$145 million.7

| Steve Parsons | Jessie Liu-Ernsting | Media |

| Managing Director | Corp Dev & IR | Paul Armstrong |

| FireFly Metals Ltd | FireFly Metals Ltd | Read Corporate |

| +61 8 9220 9030 | +1 709 800 1929 | +61 8 9388 1474 |

ABOUT FIREFLY METALS

FireFly Metals Ltd (ASX: FFM) (TSX: FFM) is an emerging copper-gold company focused on advancing the high-grade Green Bay Copper-Gold Project in Newfoundland, Canada. The Green Bay Copper-Gold Project currently hosts a Mineral Resource prepared and disclosed in accordance with the 2012 Edition of the Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (JORC Code 2012) and Canadian National Instrument 43-101 - Standards of Disclosure for Mineral Projects (NI 43-101) of 24.4Mt of Measured and Indicated Resources at 1.9% for 460Kt CuEq and 34.5Mt of Inferred Resources at 2% for 690Kt CuEq.

The Company has a clear strategy to rapidly grow the copper-gold Mineral Resource to demonstrate a globally significant copper-gold asset. FireFly has commenced a 130,000m diamond drilling program.

FireFly holds a 70% interest in the high-grade Pickle Crow Gold Project in Ontario. The current Inferred Resource stands at 11.9Mt at 7.2g/t for 2.8Moz gold, with exceptional discovery potential on the 500km2 tenement holding.

The Company also holds a 90% interest in the Limestone Well Vanadium-Titanium Project in Western Australia.

For further information regarding FireFly Metals Ltd please visit the ASX platform (ASX: FFM) or the Company's website www.fireflymetals.com.au or SEDAR+ at www.sedarplus.ca.

COMPLIANCE STATEMENTS

Mineral Resources Estimate - Green Bay Project

The Mineral Resource Estimate for the Green Bay Project referred to in this announcement and set out in Appendix A was first reported in the Company's ASX announcement dated 29 October 2024, titled "Resource increases 42% to 1.2Mt of contained metal at 2% Copper Eq" and is also set out in the Technical Reports for the Ming Copper Gold Mine titled "National Instrument 43-101 Technical Report, FireFly Metals Ltd., Ming Copper-Gold Project, Newfoundland" with an effective date of 29 November 2024 and the Little Deer Copper Project, titled "Technical Report and Updated Mineral Resource Estimate of the Little Deer Complex Copper Deposits, Newfoundland, Canada" with an effective date of 26 June 2024, each of which is available on SEDAR+ at www.sedarplus.ca.

The Company confirms that it is not aware of any new information or data that materially affects the information included in the original announcement and that all material assumptions and technical parameters underpinning the Mineral Resource Estimate in the original announcement continue to apply and have not materially changed.

Mineral Resources Estimate - Pickle Crow Project

The Mineral Resource Estimate for the Pickle Crow Project referred to in this announcement was first reported in the Company's ASX announcement dated 4 May 2023, titled "High-Grade Inferred Gold Resource Grows to 2.8Moz at 7.2g/t" and is also set out in the Technical Report for the Pickle Crow Project, titled "NI 43-101 Technical Report Mineral Resource Estimate Pickle Crow Gold Project, Ontario, Canada" with an effective date of 29 November 2024, as amended on 11 June 2025, available on SEDAR+ at www.sedarplus.ca.

The Company confirms that it is not aware of any new information or data that materially affects the information included in the original announcement and that all material assumptions and technical parameters underpinning the Mineral Resource Estimate in the original announcement continue to apply and have not materially changed.

Metal equivalents for Mineral Resource Estimates

Metal equivalents for the Mineral Resource Estimates have been calculated at a copper price of US$8,750/t, gold price of US$2,500/oz and silver price of US$25/oz. Individual Mineral Resource grades for the metals are set out in Appendix A of this announcement. Copper equivalent was calculated based on the formula CuEq(%) = Cu(%) + (Au(g/t) x 0.82190) + (Ag(g/t) x 0.00822).

Metallurgical factors have been applied to the metal equivalent calculation. Copper recovery used was 95%. Historical production at the Ming Mine has a documented copper recovery of ~96%. Precious metal (gold and silver) metallurgical recovery was assumed at 85% on the basis of historical recoveries achieved at the Ming Mine in addition to historical metallurgical test work to increase precious metal recoveries.

In the opinion of the Company, all elements included in the metal equivalent calculations have a reasonable potential to be sold and recovered based on current market conditions, metallurgical test work, the Company's operational experience and, where relevant, historical performance achieved at the Green Bay project whilst in operation.

Exploration Results

Previously reported Exploration Results at the Green Bay Project referred to in this announcement were first reported in accordance with ASX Listing Rule 5.7 in the Company's ASX announcements dated 31 August 2023, 11 December 2023, 16 January 2024, 4 March 2024, 21 March 2024, 29 April 2024, 19 June 2024, 3 September 2024, 16 September 2024, 3 October 2024, 10 December 2024, 12 February 2025, 25 March 2025, 7 May 2025, 17 July 2025 and 24 July 2025.

Original announcements

FireFly confirms that it is not aware of any new information or data that materially affects the information included in the original announcements and that, in the case of estimates of Mineral Resources, all material assumptions and technical parameters underpinning the Mineral Resource Estimates in the original announcements continue to apply and have not materially changed. The Company confirms that the form and context in which the Competent Persons' and Qualified Persons' findings are presented have not been materially modified from the original market announcements.

COMPETENT PERSON AND QUALIFIED PERSON STATEMENTS

The information in this announcement that relates to new metallurgical test work is based on and fairly represents information compiled by Mr Jared Dietrich, a Competent Person who is a member of the Australasian Institute of Mining and Metallurgy. Mr Dietrich is a full-time employee of FireFly Metals Ltd. Mr Dietrich has sufficient experience that is relevant to the style of mineralisation, processing and type of deposit under consideration and to the activity being undertaken to qualify as a Competent Person as defined in the 2012 Edition of the 'Australasian Code for the Reporting of Exploration Results, Mineral Resources and Ore Reserves'. Mr Dietrich consents to the inclusion in this announcement of the matters based on his information in the form and context in which it appears.

Qualified Persons

Tommaso Roberto Raponi, P.Eng., an independent consultant with Ausenco Engineering Canada ULC., is a "Qualified Persons" as defined by NI 43-101, has reviewed and approved metallurgical/process technical information contained in this announcement.

FORWARD-LOOKING INFORMATION

This announcement may contain certain forward-looking statements and projections, including statements regarding FireFly's plans, forecasts and projections with respect to its mineral properties and programs. Forward-looking statements may be identified by the use of words such as "may", "might", "could", "would", "will", "expect", "intend", "believe", "forecast", "milestone", "objective", "predict", "plan", "scheduled", "estimate", "anticipate", "continue", or other similar words and may include, without limitation, statements regarding plans, strategies and objectives.

Although the forward-looking statements contained in this announcement reflect management's current beliefs based upon information currently available to management and based upon what management believes to be reasonable assumptions, such forward-looking statements and projections are estimates only and should not be relied upon. They are not guarantees of future performance and involve known and unknown risks, uncertainties and other factors many of which are beyond the control of the Company, which may include changes in commodity prices, foreign exchange fluctuations, economic, social and political conditions, and changes to applicable regulation, and those risks outlined in the Company's public disclosures.

The forward-looking statements and projections are inherently uncertain and may therefore differ materially from results ultimately achieved. For example, there can be no assurance that FireFly will be able to confirm the presence of Mineral Resources or Ore Reserves, that FireFly's plans for development of its mineral properties will proceed, that any mineralisation will prove to be economic, or that a mine will be successfully developed on any of FireFly's mineral properties. The performance of FireFly may be influenced by a number of factors which are outside of the control of the Company, its directors, officers, employees and contractors. The Company does not make any representations and provides no warranties concerning the accuracy of any forward-looking statements or projections, and disclaims any obligation to update or revise any forward-looking statements or projections based on new information, future events or circumstances or otherwise, except to the extent required by applicable laws.

APPENDIX A - Metallurgical Testwork Summary

The following is a high-level summary of the metallurgical testwork program completed by SGS at the Lakefield test facility in Ontario, Canada. This work was completed under the supervision of both FireFly and Ausenco.

The objective of metallurgical testwork program was to build upon historical testwork and recorded operational data from the Ming Mine/Nugget Pond operation collected between 2012 and 2023.

Improvement in metal recovery in comparison to historical levels was tested by applying modern-day technology and a processing flow specifically designed for copper extraction. The historical 500ktpa Nugget Pond mill was constructed in 1995 for treatment of narrow-vein high-grade gold ore and subsequently modified to accommodate copper flotation.

Sample Selection

Over 1,200kg of recent diamond drill core was collected from all geological domains within the Ming Mine, as well as spatially through the operating levels. Additionally, over 300kg of recently mined Footwall Zone (FWZ) and Volcanogenic Massive Sulphide (VMS) style mineralisation was collected from active mine development.

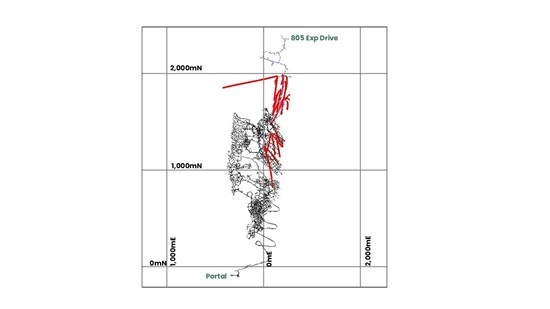

Samples were sent to SGS in Q1 2025. The samples were designated as geological domain composites, geological variability samples, and mine-plan production composites (Table 1). A map showing the location of drillholes selected for metallurgical sampling is shown in Figure 2.

Table 1: List of sample domains and associated grades

| Sample Description | Sample Type | Copper (%) | Gold (g/t) | Silver (g/t) |

| ROM (Y1-5) | Mine Plan Composite | 2.54 | 1.49 | 10.5 |

| Blend 1 (50%LFZ / 50%VMS) | Mined Product Bulk Sample | 3.06 | 0.75 | 8.00 |

| Blend 2 (70%LFZ / 30%VMS) | Mined Product Bulk Sample | 3.43 | 0.60 | 7.00 |

| LFZ (DOM1) | Domain Composite | 2.18 | 0.14 | 3.10 |

| VMS (DOM2) | Domain Composite | 2.23 | 1.71 | 11.9 |

| LFZ1 | Domain 1 Variability | 1.95 | 0.09 | 2.50 |

| LFZ2 | Domain 1 Variability | 1.27 | 0.05 | 1.00 |

| LFZ3 | Domain 1 Variability | 1.21 | 0.05 | < 0.5 |

| LFZ4 | Domain 1 Variability | 0.93 | 0.06 | 0.60 |

| LFZ5 | Domain 1 Variability | 1.22 | 0.08 | 1.40 |

| LFZ6 | Domain 1 Variability | 1.29 | 0.06 | 1.00 |

| LFZD1 | Domain 1 - Contact Waste | 0.01 | 0.01 | 0.50 |

| LFZW1 | Domain 1 Variability | 1.33 | 0.06 | 1.40 |

| LFZW2 | Domain 1 Variability | 1.20 | 0.11 | 1.40 |

| UFZ1 | Domain 1 Variability | 0.88 | 0.05 | 1.00 |

| DOM1VS1 | Domain 1 Variability | 2.22 | 0.16 | 2.90 |

| DOM1VS2 | Domain 1 Variability | 1.83 | 0.08 | 3.00 |

| MNZ1 | Domain 2 Variability | 3.24 | 1.39 | 13.0 |

| MNZ2 | Domain 2 Variability | 3.51 | 1.38 | 11.0 |

| MNZ3 | Domain 2 - Contact Waste | 0.28 | 1.33 | 5.70 |

| MNZ4 | Domain 2 Variability | 1.10 | 1.19 | 5.30 |

| MNZ5 | Domain 2 Variability | 3.46 | 1.43 | 6.90 |

| MSZ1 | Domain 2 Variability | 3.31 | 1.89 | 25.9 |

| DOM2VS1 | Domain 2 Variability | 2.27 | 3.96 | 21.0 |

| DOM2VS2 | Domain 2 Variability | 1.88 | 0.75 | 8.50 |

Figure 2: Plan view of drillholes sampled for the metallurgical testwork program

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/11430/261240_dd24358504936b91_004full.jpg

Comminution Testing

Fourteen comminution samples were selected for testing covering various mineralisation, contact waste and alterations across the geological domains. Table 2 outlines the ore breakage testing completed at SGS in support of the economic studies design, such as SMC Test Axb, Bond Rod Mill Work Index (RWi), Bond Ball Mill Work Index (BWi) with a 106 µm closing size, and Bond Abrasion Index.

The testing demonstrated that mineralised samples yielded consistent Bond Ball Work Index hardness values from 10.4 to 11.4 kWh/t, and Ore Competency (Axb) was classified as low for the VMS, and moderate for the Lower Footwall Zone (LFZ). This is indicative of relatively low power requirements to crush the mineralised material.

The low Abrasive Index results (0.1g-0.18g) suggests wear rates on milling components, such as grinding media and liners, will be relatively low leading to lower maintenance and consumable costs.

| Sample Description | Abrasion Index | SMC - Axb | Bond RWI | Bond BWI | Competency Classification |

| LFZ - mineralised | 0.12 | 47.6 | 10.7 | 11.2 | Moderately competent |

| LFZ - contact waste | 0.18 | 30.2 | n/a | 11.4 | Competent |

| VMS - mineralised | 0.10 | 90.2 | 6.6 | 11.0 | Low competency |

| VMS - contact waste | n/a | 70.1 | n/a | 10.4 | Low competency |

Table 2: Comminution Testing Results

Flotation Testing

Before the flotation testing commenced, a review was conducted on past milling operations of the Ming Mine deposit to identify opportunities for metal recovery improvements and integration of modern-day flotation technologies. Based on the review, the testwork program completed tested the benefit of:

- Different primary grinds with varying mill media materials

- Different pH, Eh, collectors and depressants

- Integration of rougher concentrate regrind and varying regrind targets

- Integration of cleaner concentrate scalping

- Integration of gravity gold/silver recovery

- Integration of pyrite-associated gold scavenging/upgrading

To date, 61 open circuit flotation tests have been completed, firstly with the domain composites to develop the baseline metallurgical performance achievable within each geological domain.

Following this, the production composites were tested in different blended feed ratios for the major domains to confirm amenability to blending, and optimized flotation chemistry.

Lastly, variability testing was performed within each major domain to assess metallurgical response to samples containing high zinc, high pyrite, and various high/low copper grades as expected in the mine product, utilising the final process flowsheet as shown in the Figure 3.

Figure 3: Process flow sheet used for the Ming metallurgical testwork

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/11430/261240_dd24358504936b91_005full.jpg

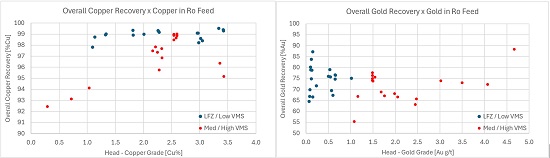

The testing has demonstrated very high and reproducible (+98% average) copper recoveries to the final concentrate, with high gold/silver recovered (65 to 90% - 75% global average) depending on the blend of LFZ/VMS in feed, and copper head grade dictating the optimal blend of the recovered copper and pyrite con as outlined in the Table 3.

The major improvements achieved, as compared to past milling operations at Nugget Pond, was the introduction of the concentrate regrind stage which enables for a more selective cleaning flotation stage/higher concentrate product, which then yields a secondary benefit, being the recovery of a gold-bearing pyrite concentrate into the same product, whilst still achieving >20% copper grade in the final product.

| Sample Description | Test Description | Copper Recovery (%) | Gold Recovery (%) | Silver Recovery (%) |

| LFZ (DOM1) | Open Circuit Rougher + Cleaner | 99 | 79 | 83 |

| VMS (DOM2) | Open Circuit Rougher + Cleaner | 96 | 60 | 67 |

| Blend 1 (50%LFZ/50%VMS) | Open Circuit Rougher + Cleaner | 99 | 73 | 80 |

| Blend 2 (70%LFZ/30%VMS) | Open Circuit Rougher + Cleaner | 99 | 77 | 80 |

| ROM (Y1-5) | Open Circuit Rougher + Cleaner | 99 | 75 | 84 |

| ROM (Y1-5) | Locked Cycle Test | 99 | 76 | 88 |

| LFZ Variability | Open Circuit Rougher + Cleaner | 98 | 74 | 75 |

| VMS Variability | Open Circuit Rougher + Cleaner | 96 | 72 | 73 |

Table 3: Ming Flotation testwork results

As shown in Figure 4, when the flotation test results are grouped in two mineralogical datasets, there is an observable correlation between copper head grade and copper recoveries between 92.5 to 99.5%, whereas gold recoveries were observed between 55 to 90%, which is a negligible correlation to gold head grade.

Figure 4: Copper and gold flotation recoveries versus head grade

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/11430/261240_ffmfig4.jpg

Pyrite Tails Gold/Silver Recovery Testing

Through the generation of pyrite (high sulphur %) tailings from the various flotation tests, additional investigation was completed to characterise the gold/silver association followed by testing via modern-day and conventional gold/silver technologies (Table 4). From this review, the testwork program has tested the benefit of the following initiatives:

- Integration of gravity recovery via concentrators and tables

- Conventional pre-oxidated cyanidation with and without regrind

- Conventional flash flotation, hydrocycloning or other density separation

- Review of other leaching technologies

To date, eight leach bottle rolls have been completed, as well as 16 gravity recovery tests, with the remainder of the program outlined above to be completed in the coming months.

| Sample Description | Test Description | Feed Grade - Gold - g/t | Feed Grade - Silver - g/t | Stage Gold Recovery (%) | Stage Silver Recovery (%) |

| ROM5 Pyrite Tailings | Conventional leach w/ regrind | 0.7 | 3.9 | 71 | 83 |

| ROM5 Pyrite Tailings | Gravity recovery via Mozley Table | 1.9 | 11.8 | 13 | 8 |

| VMS Variability | Gravity recovery via Mozley Table | 1.9 | 11.8 | 8 | 17 |

Table 4: Pyrite Tails Gold/Silver Recovery Testing

APPENDIX B

Green Bay Copper-Gold Project Mineral Resources

Ming Deposit Mineral Resource Estimate

| TONNES | COPPER | GOLD | SILVER | CuEq | ||||

| (Mt) | Grade (%) | Metal ('000 t) | Grade (g/t) | Metal ('000 oz) | Grade (g/t) | Metal ('000 oz) | Grade (%) | |

| Measured | 4.7 | 1.7 | 80 | 0.3 | 40 | 2.3 | 340 | 1.9 |

| Indicated | 16.8 | 1.6 | 270 | 0.3 | 150 | 2.4 | 1,300 | 1.8 |

| TOTAL M&I | 21.5 | 1.6 | 340 | 0.3 | 190 | 2.4 | 1,600 | 1.8 |

| Inferred | 28.4 | 1.7 | 480 | 0.4 | 340 | 3.3 | 3,000 | 2.0 |

Little Deer Mineral Resource Estimate

| TONNES | COPPER | GOLD | SILVER | CuEq | ||||

| (Mt) | Grade (%) | Metal ('000 t) | Grade (g/t) | Metal ('000 oz) | Grade (g/t) | Metal ('000 oz) | Grade (%) | |

| Measured | - | - | - | - | - | - | - | - |

| Indicated | 2.9 | 2.1 | 62 | 0.1 | 9 | 3.4 | 320 | 2.3 |

| TOTAL M&I | 2.9 | 2.1 | 62 | 0.1 | 9 | 3.4 | 320 | 2.3 |

| Inferred | 6.2 | 1.8 | 110 | 0.1 | 10 | 2.2 | 430 | 1.8 |

GREEN BAY TOTAL MINERAL RESOURCE ESTIMATE

| TONNES | COPPER | GOLD | SILVER | CuEq | ||||

| (Mt) | Grade (%) | Metal ('000 t) | Grade (g/t) | Metal ('000 oz) | Grade (g/t) | Metal ('000 oz) | Grade (%) | |

| Measured | 4.7 | 1.7 | 80 | 0.3 | 45 | 2.3 | 340 | 1.9 |

| Indicated | 19.7 | 1.7 | 330 | 0.2 | 154 | 2.6 | 1,600 | 1.9 |

| TOTAL M&I | 24.4 | 1.7 | 400 | 0.3 | 199 | 2.5 | 2,000 | 1.9 |

| Inferred | 34.6 | 1.7 | 600 | 0.3 | 348 | 3.1 | 3,400 | 2.0 |

- Mineral Resource Estimates for the Green Bay Copper-Gold Project, incorporating the Ming Deposit and Little Deer Complex, are prepared and reported in accordance with the JORC Code 2012 and NI 43-101.

- Mineral Resources have been reported at a 1.0% copper cut-off grade.

- Metal equivalents for the Mineral Resource Estimate have been calculated at a copper price of US$8,750/t, gold price of US$2,500/oz and silver price of US$25/oz. Metallurgical recoveries have been set at 95% for copper and 85% for both gold and silver. Copper equivalent was calculated based on the formula: CuEq(%) = Cu(%) + (Au(g/t) x 0.82190) + (Ag(g/t) x 0.00822).

- Totals may vary due to rounding.

APPENDIX C - Metallurgical Samples from Drillholes

Collar co-ordinates and orientation are listed in the local Ming Mine grid, which is rotated +35 degrees from NAD83 True North. All drillholes used in the metallurgical testwork sampling have been previously announced by FireFly.

Zone codes used in the tables below are as follows: LFZ - Lower Footwall Zone; UFZ - Upper Footwall Zone; MNZ - Ming North Zone VMS; MSZ - Ming South Zone VMS; 1807 - 1807 VMS Lense.

Collar Coordinates for drillholes used in metallurgical testwork sampling

| Hole Number | Easting | Northing | RL | Azi | Dip | Drilled Length (m) |

| MUG23_003 | 1092.332 | 1565.039 | -805.116 | 22 | -26 | 231 |

| MUG23_004 | 1091.244 | 1565.595 | -805.433 | 12 | -24 | 246 |

| MUG23_012 | 1059.277 | 1510.037 | -806.793 | 146 | -57 | 438 |

| MUG24_001 | 1075.0 | 1381.0 | -764.0 | 163 | -50 | 360 |

| MUG24_002 | 993 | 1242 | -608 | 163 | -12 | 465 |

| MUG24_004 | 993 | 1242 | -608 | 21 | -57 | 390 |

| MUG24_009 | 1004.0 | 1251.0 | -610.0 | 133 | -43 | 366 |

| MUG24_012 | 1061.009 | 1509.396 | -808.341 | 180 | -80 | 339 |

| MUG24_015 | 1191.4 | 1724.0 | -825.6 | 51.07 | -82.08 | 552 |

| MUG24_019 | 1191.0 | 1724.0 | -826.0 | 174 | -65 | 420 |

| MUG24_020 | 1154 | 1715 | -825 | 184 | -71 | 432 |

| MUG24_021 | 1154.0 | 1715.0 | -825.0 | 10 | -69 | 411 |

| MUG24_021 | 1154 | 1715 | -825 | 10 | -69 | 411 |

| MUG24_024 | 1243.0 | 1716.0 | -826.0 | 146 | -86 | 501 |

| MUG24_025 | 1130 | 1719 | -825 | 352 | -89 | 516 |

| MUG24_029 | 1130.0 | 1719.0 | -825.0 | 10 | -70 | 549 |

| MUG24_035 | 1130.2 | 1719.2 | -825.1 | 184 | -84 | 492 |

| MUG24_036 | 1191.38 | 1723.955 | -825.638 | 190 | -65 | 543 |

| MUG24_039 | 1136.7 | 1973.1 | -842.1 | 256 | -32 | 681 |

| MUG24_041 | 1217.09 | 1719.875 | -825.646 | 30 | -72 | 579 |

| MUG24_050 | 1217.0 | 1720.0 | -826.0 | 100 | -80 | 477 |

| MUG24_051 | 1127 | 1359 | -757 | 145 | -67 | 345 |

| MUG24_055 | 1127.0 | 1359.0 | -757.0 | 169 | -41 | 315 |

| MUG24_058 | 1200 | 1965 | -839 | 15 | -81 | 623 |

| MUG24_061 | 1070.7 | 1384.0 | -765.1 | 187 | -55 | 417 |

| MUG24_062 | 1234 | 1974 | -846 | 148 | -83 | 552 |

| MUG24_063 | 1200.0 | 1965.0 | -839.0 | 169 | -87 | 561 |

| MUG24_066 | 1222.873 | 1924.163 | -841.596 | 166 | -76 | 582 |

| MUG24_069 | 1070.7 | 1384.0 | -765.1 | 110 | -63 | 384 |

| MUG24_070 | 1199.712 | 1964.776 | -839.25 | 175 | -73 | 531 |

| MUG24_078 | 1070.7 | 1384.0 | -765.1 | 138 | -54 | 330 |

| MUG24_081 | 995.7973 | 1248.134 | -610.098 | 127 | -59 | 432 |

| MUG24_083 | 1140.0 | 1973.4 | -844.0 | 162 | -88 | 585 |

| MUG25_018 | 1139.979 | 1973.410 | -844.0 | 186 | -81 | 351 |

| MUG25_032 | 1139.979 | 1973.410 | -844.0 | 188 | -17 | 270 |

Metallurgical Testwork Bulk Sampling Results

| Domain | Description | Weight (Kg) | Drillhole ID | From-To | Cu % | Au g/t | Ag g/t | Zn % | Zone | Lithology Description |

| DOMAIN 0 | First 5 years ROM Composite | 141.5 | MUG24_009 | 214.3-247.9m | 2.35 | 0.14 | 2.59 | 0.02 | LFZ | Chlorite altered felsics with CPY stringers |

| MUG24_018 | 65.25-73.45m | 3.57 | 2.67 | 24.84 | 0.70 | MNZ | Massive sulphides | |||

| MUG24_019 | 92.45-97.5m | 1.36 | 3.34 | 19.68 | 0.30 | MSZ | Sericite/silica altered felsics with CPY stringers and massive | |||

| MUG24_025 | 92.45-97.5m | 3.59 | 1.81 | 11.02 | 0.21 | MNZ | Sulphides | |||

| MUG24_055 | 41.80-46.8m | 1.5 | 0.12 | 2.22 | 0.03 | UFZ | Chlorite altered felsics with CPY stringers | |||

| MUG24_063 | 250.15-258.0m | 2.49 | 3.01 | 31.87 | 1.60 | MNZ | Massive Sulphides | |||

| MUG24_063 | 261.0-269.95m | 1.60 | 2.13 | 15.43 | 1.30 | MSZ | Massive Sulphides | |||

| MUG24_069 | 124.0-141.0m | 2.20 | 0.09 | 2.95 | 0.06 | LFZ | Chlorite altered Felsics with CPY stringers | |||

| TOTAL | 2.32 | 1.10 | 9.47 | 0.34 | ||||||

| DOMAIN 1 | General Footwall Zone Composite | 172.4 | MUG24_081 | 193.5-221.20m | 2.46 | 0.12 | 2.28 | 0.02 | LFZ | Chlorite altered felsics with CPY stringers |

| MUG24_078 | 155-178.30m | 2.35 | 0.15 | 2.69 | 0.01 | LFZ | Chlorite altered felsics with CPY stringers | |||

| MUG24_024 | 291.95-320.70m | 2.19 | 0.05 | 2.80 | 0.01 | LFZ | Chlorite altered felsics with CPY stringers | |||

| MUG24_015 | 231.85-235.85m | 1.54 | 0.05 | 2.33 | 0.1 | UFZ | Chlorite altered felsics with CPY stringers | |||

| MUG24_019 | 222.50-227.50m | 2.02 | 0.08 | 2.44 | 0.03 | UFZ | Sericite/Chlorite altered felsics with PYR-CPY stringers | |||

| MUG24_051 | 50.0-53.53m | 1.43 | 0.15 | 2.03 | 0.03 | UFZ | Sericite/Chlorite altered felsics with PYR-CPY stringers | |||

| MUG24_002 | 222.9-244.9m | 2.42 | 0.15 | 2.53 | 0.06 | LFZ | Chlorite altered felsics with CPY stringers | |||

| MUG24_010 | 260.85-279.70m | 1.93 | 0.15 | 2.47 | 0.01 | LFZ | Chlorite altered felsics with CPY stringers | |||

| TOTAL | 2.13 | 0.11 | 2.40 | 0.02 | ||||||

| LFZ Comminution Sample No. 1 | 62.9 | MUG24_001 | 126.65-177.15m | 1.65 | 0.11 | 1.91 | 0.02 | LFZ | Chlorite altered felsics with CPY stringers, minor gabbro qz vein interval | |

| DOMAIN 1 | LFZ Comminution Sample No. 2 | 66.3 | MUG24_036 | 292.4-339.90m | 1.06 | 0.08 | 1.92 | 0.01 | LFZ | Chlorite altered felsics with CPY stringers, felsic intrusive waste interval |

| LFZ Comminution Sample No. 3 | 62 | MUG24_021 | 356.95-405.70m | 1.29 | 0.04 | 1.33 | 0.02 | LFZ | Chlorite altered felsics with CPY stringers, gabbro qz vein interval | |

| LFZ Comminution Sample No. 4 | 45.2 | MUG24_002 | 222.9-273.40m | 1.85 | 0.12 | 1.72 | 0.03 | LFZ | Chlorite altered felsics with CPY stringers | |

| LFZ Comminution Sample No. 5 | 63.1 | MUG24_050 | 321.05-367.0m | 1.1 | 0.06 | 1.44 | 0.01 | LFZ | Chlorite altered felsics with CPY stringers | |

| LFZ Comminution Sample No. 6 | 71.4 | MUG24_066 | 362.25-420.30m | 1.37 | 0.04 | 1.68 | 0.02 | LFZ | Chlorite altered felsics with CPY stringers | |

| UFZ Comminution Sample No. 1 | 60.4 | MUG24_061 | 29.5-78.4m | 1.0 | 0.05 | 0.9 | 0.02 | UFZ | Chlorite altered felsics with CPY stringers, minor gabbro qz vein interval | |

| LFZ Comminution Waste Dilution Sample No. 1 | 82 | MUG24_062 | 426.75-493.25 | 0.84 | 0.04 | 1.06 | 0.02 | LFZ | Chlorite altered felsics with CPY stringers, with multiple gabbro intervals | |

| LFZ Comminution Waste Dilution Sample No. 2 | 63 | MUG24_019 | 284.3-331.35m | 2.18 | 0.24 | 3.15 | 0.02 | LFZ | Chlorite altered felsics with CPY stringers, with gabbro and felsic intrusive interval | |

| LFZ Comminution Dyke Sample No. 1 | 51.1 | MUG24_078 | 45.0-83.80m | 0.01 | 0.01 | 0.14 | 0.01 | Waste | Gabbro | |

| DOMAIN 1 Variability Sample No. 1 | 24.2 | MUG24_021 | 301.95-321.40m | 2.2 | 0.07 | 2.23 | 0.04 | LFZ | Chlorite altered felsics with CPY stringers | |

| DOMAIN 1 | DOMAIN 1 Variability Sample No. 2 | 27.8 | MUG23_012 | 207.20-229.55m | 2.13 | 0.16 | 2.33 | 0.01 | LFZ | Chlorite altered felsics with CPY stringers, minor gabbro intervals |

| DOMAIN 2 | VMS Massive Sulphide Composite | 125 | MUG24_029 | 71.70-85.20m | 5.5 | 2.65 | 16.78 | 0.35 | MNZ | Sericite/silica altered felsics with CPY stringers and massive sulphides |

| MUG24_083 | 242.70-269.40m | 1.73 | 1.16 | 9.88 | 0.99 | MNZ | Massive sulphides and Serice/silica altered felsics with CPY/PYR stringers | |||

| MUG24_070 | 217.55-222.15m | 2.26 | 5.64 | 25.03 | 0.65 | MNZ | Massive sulphides | |||

| MUG24_070 | 232.45-240.35m | 1.15 | 2.89 | 20.10 | 1.02 | MSZ | Massive sulphides | |||

| MUG24_015 | 104.3-114-35m | 1.24 | 3.65 | 12.14 | 0.79 | MSZ | Massive sulphides to semi-massive sulphides | |||

| MUG24_020 | 82.95-92.95m | 2.28 | 0.66 | 3.43 | 0.06 | MSZ | Sericite/silica altered felsics with CPY and PYR stringers | |||

| MUG24_041 | 163.1-167.70m | 1.17 | 1.46 | 9.35 | 1.14 | MSZ | Massive sulphides and Serice/silica altered felsics with CPY/PYR stringers | |||

| MUG24_021 | 134.5-139.5m | 3.32 | 0.44 | 6.28 | 0.18 | MSZ | Sericite/silica altered felsics with CPY stringers and massive sulphides | |||

| MUG24_021 | 96.2-99.0m | 2.17 | 1.69 | 12.85 | 2.18 | MNZ | Massive sulphides and Serice/silica altered felsics with CPY/PYR stringers | |||

| TOTAL: | 2.26 | 1.88 | 11.84 | 0.69 | ||||||

| MNZ Comminution Sample No. 1 | 43 | MUG23_003 | 126.65-163.70m | 9.86 | 1.13 | 2.48 | 0.49 | MNZ | Massive sulphides, minor gabbro and Sericite/silica altered felsics | |

| MNZ Comminution Sample No. 2 | 39 | MUG23_004 | 161.45-192.60m | 9.61 | 1.53 | 3.55 | 0.49 | MNZ | Sericite/silica altered felsics with CPY and PYR stringers with minor massive sulphides | |

| MNZ Comminution Sample No. 4 | 38.77 | MUG25_018 | 214.75-222.65 | 0.97 | 1.28 | 5.27 | 0.18 | MNZ | Massive sulphides, 50% gabbro and footwall mafic/sediments dilution | |

| MNZ Comminution Sample No. 5 | 41.26 | MUG25_032 | 213.5-219.5 | 5.99 | 2.18 | 99.17 | 2.69 | MNZ | Sericite/silica altered felsics with CPY and PYR stringers with minor massive sulphides, | |

| DOMAIN 2 Variability Sample No. 1 | 34.4 | MUG24_058 | 289.15-311.05 | 2.07 | 3.13 | 19.76 | 1.5 | MNZ | Massive sulphides with minor Sericite/silica altered felsics | |

| Domain 2 | DOMAIN 2 Variability Sample No. 2 | 19.4 | MUG24_035 | 49.0-64.5m | 1.84 | 0.9 | 7.63 | 0.18 | MNZ | Sericite/silica altered felsics with CPY stringers and minor massive sulphides |

| DOMAIN 2 Variability Sample No. 3 | 38.09 | MUG25_032 | 219.5-230.7 | 3.75 | 0.78 | 6.23 | 0.1 | MNZ | Massive sulphides with minor Sericite/silica altered felsics with CPY stringers and | |

| 1807 | 1807 Variability Sample | 8.8 | MUG24_039 | 335.5-342.2 | 0.69 | 2.11 | 24.75 | 0.11 | 1807 | Massive sulphides with minor Gabbro |

APPENDIX D - JORC CODE, 2012 EDITION

Table 1

Section 1 - Sampling Techniques and Data for Metallurgical sampling (Criteria in this section apply to all succeeding sections)

| Criteria | JORC Code explanation | Commentary |

| Sampling techniques |

|

|

| Drilling techniques |

|

|

| Drill sample recovery |

|

|

| Logging |

|

|

| Sub-sampling techniques and sample preparation |

|

|

| Quality of assay data and laboratory tests |

|

|

| Verification of sampling and assaying |

|

|

| Location of data points |

|

|

| Data spacing and distribution |

|

|

| Orientation of data in relation to geological structure |

|

|

| Sample security |

|

|

| Audits or reviews |

|

|

Section 2 - Reporting of Exploration Results (Criteria in this section apply to all succeeding sections)

| Criteria | JORC Code explanation | Commentary |

| Mineral tenement and land tenure status |

|

|

| Exploration done by other parties |

|

|

| Geology |

|

|

| Drill hole Information |

|

|

| Data aggregation methods |

|

|

| Relationship between mineralisation widths and intercept lengths |

|

|

| Diagrams |

|

|

| Balanced reporting |

|

|

| Other substantive exploration data |

|

|

| Further work |

|

|

1 The first economic study (Scoping Study) will be prepared in accordance with 'Scoping Study' requirements for the purposes of 2012 Edition of the Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (JORC Code 2012) and 'Preliminary Economic Assessment' requirements for the purposes of the 2019 Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Definition Standards and Canadian National Instrument 43-101 - Standards of Disclosure for Mineral Projects (NI 43-101).

2 One final tranche of the capital raising (the T2 Placement) remains to be competed, as it is subject to receiving shareholder approval at a general meeting planned to be held on 28 August 2025.

3 Cash, receivables and liquid investments position at 30 June 2025, plus A$10 million proceeds received from the Share Purchase Plan which was completed on 14 July 2025, and anticipated net proceeds from the second tranche of the T2 Placement of ~A$26.6 million, which is subject to shareholder approval at a general meeting planned to be held on 28 August 2025, noting that there is no guarantee that shareholders will vote in favour of the issuance of shares under the T2 Placement.

4 Please refer to ASX announcement dated 29 October 2024 and Appendix B of this announcement for further details of the Mineral Resource Estimate (MRE). The current MRE contains 24.4Mt for 199koz of contained gold in the Measured and Indicated Mineral Resource categories, and 34.6Mt for 348koz in the lower-confidence Inferred Mineral Resource category.

5 Timeframes are indicative and may be subject to change.

6 One final tranche of the capital raising (the T2 Placement) remains to be competed, as it is subject to receiving shareholder approval at a general meeting planned to be held on 28 August 2025.

7 Cash, receivables and liquid investments position at 30 June 2025, plus A$10 million proceeds received from the Share Purchase Plan which was completed on 14 July 2025, and anticipated net proceeds from the second tranche of the T2 Placement of ~A$26.6 million, which is subject to shareholder approval at a general meeting planned to be held on 28 August 2025, noting that there is no guarantee that shareholders will vote in favour of the issuance of shares under the T2 Placement.

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/261240

Source: FireFly Metals Ltd.