Highlights:

- A mineralised NW structural Corridor has been identified at Sierra Inesperada as a result of the 2019 December quarterly exploration program.

- Sierra Inesperada represents a new exploration area for the Company - located SW of the Guanaco Mine area.

- Attractive new intersections observed from the 4,806 meters reverse circulation ("RC") and diamond drill hole ("DDH") campaign included:

- 8.0m @ 4.26 g/t Au incl. 1m @ 19.17 g/t Au

- 14m @ 2.90 g/t Au incl. 1.0m @ 13.77 g/t Au

- 4.05m @ 3.99 g/t Au incl. 0.63m @ 13.80 g/t Au

Sydney, Australia--(Newsfile Corp. - January 30, 2020) - Austral Gold Limited (ASX: AGD) (TSXV: AGLD) ("Austral" or the "Company") is pleased to announce exploration drilling results from its recent drill program at the Sierra Inesperada property, which is located near the Company's Guanaco Mine.

Sierra Inesperada is located approximately seven kilometers southwest of the Guanaco Mine. During the fourth quarter of 2019, the Company conducted a drill campaign comprising 48 holes and 4,806 meters, with 4,256 meters of RC and 550 meters of DDH drilling.

Austral Gold's Chief Executive Officer Stabro Kasaneva said: "Our technical team is very encouraged by these drilling results. We will analyze these results further as we plan our next drilling program for Q1 2020, as well as metallurgical testing and a geophysics campaign using ground magnetometry at Sierra Inesperada."

A mineralised structural corridor was identified, which is oriented N60 W / 85 SW, with a thickness that varies between 5 and 40 meters and an interpreted depth greater than 150 meters and strike of 200 meters. The structures have brecciated textures with fragments of gray quartz, vuggy silica and lithics. The wall rock is affected by an advanced argillic alteration with moderate to intense silicification and a strong presence of alunite.

The oxidation zone is recognized by the presence of iron oxides that mostly correspond to hematite-jarosite and traces of copper oxides. The sulphide zone is clearly represented by the weak to high presence of disseminated pyrite in irregular veinlets. Gray sulphides are observed as enargite and traces of chalcocite, which are arranged as a very thin patina in the pyrite.

The host rock of the mineralization corresponds to a pyroclastic sequence formed by layers of tuffs and lithic tuffs of andesitic-dacitic composition, defined as Inesperada Hydro-magmatic Sequence. It covers a unit of green porphyric andesites with medium-sized plagioclase phenocrystals.

The gold grades observed varied mostly in a range between 0.5 gr/t and 3 gr/t Au, with a maximum gold grade of 19.17 gr/t Au. See Table 1 for all mineralized intercepts.

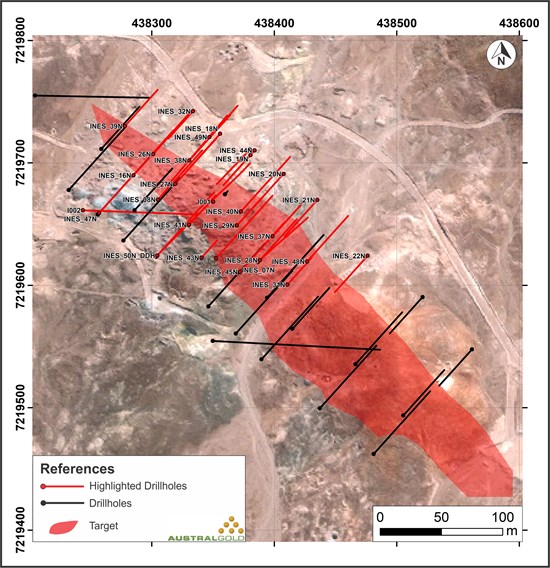

The Company assumes that the geological characteristics and orientation of the structural patterns observed in the veins will provide an important exploration guide to recognize the mineral potential of the Sierra Inesperada. A location map of the Sierra Inesperada project is set out in Figure 1.

Figure 1: Location map Sierra Inesperada

To view an enhanced version of Figure 1, please visit:

https://orders.newsfilecorp.com/files/690/51953_db87bae354d408f3_002full.jpg

SIERRA INESPERADA PROJECT - Drilling Results*

| Drill hole | From (m) | To (m) | Length (m) | Au (g/t) | Ag (g/t) | Cu (g/t) | Au Eq (g/t) |

| INES_7N | 28 | 34 | 6 | 1.91 | 12 | 193 | 2.05 |

| 46 | 54 | 8 | 1.53 | 16 | 83 | 1.71 | |

| INES_8N | 36 | 40 | 4 | 1.00 | 6 | 106 | 1.06 |

| 73 | 74 | 1 | 1.15 | 15 | 56 | 1.32 | |

| 78 | 86 | 8 | 2.82 | 16 | 114 | 3.00 | |

| Including 78-79 (1m) : 3,90 g/t Au | |||||||

| Including 81-83m (2m): 4,79 g/t Au | |||||||

| Including 84-86 (2m) : 2,95 g/t Au | |||||||

| 101 | 107 | 6 | 1.26 | 6 | 105 | 1.33 | |

| INES_15N | 10 | 26 | 16 | 1.05 | 8 | 215 | 1.14 |

| 28 | 32 | 4 | 1.31 | 7 | 217 | 1.39 | |

| 42 | 47 | 5 | 1.43 | 20 | 174 | 1.65 | |

| 48 | 49 | 1 | 1.57 | 21 | 265 | 1.80 | |

| 54 | 57 | 3 | 1.15 | 8 | 101 | 1.24 | |

| 54 | 67 | 13 | 1.80 | 64 | 701 | 2.52 | |

| INES_16N | 60 | 64 | 4 | 1.87 | 23 | 127 | 2.13 |

| 77 | 79 | 2 | 1.14 | 36 | 131 | 1.55 | |

| 80 | 87 | 7 | 2.17 | 44 | 159 | 2.67 | |

| Including 85-86m (1m): 5,03 g/t Au | |||||||

| 92 | 100 | 8 | 1.2 | 8 | 158 | 1.27 | |

| 102 | 103 | 1 | 1.2 | 21 | 336 | 1.45 | |

| INES_18N | 12 | 16 | 4 | 1.3 | 24 | 686 | 1.57 |

| 64 | 65 | 1 | 1.2 | 5 | 36 | 1.21 | |

| 66 | 68 | 2 | 1.2 | 14 | 33 | 1.31 | |

| INES_19N | 38 | 46 | 8 | 1.2 | 48 | 53 | 1.71 |

| 52 | 58 | 6 | 1.3 | 16 | 63 | 1.49 | |

| 60 | 67 | 7 | 1.9 | 32 | 93 | 2.28 | |

| 67 | 76 | 9 | 4.6 | 31 | 73 | 4.98 | |

| Including 69-73m (4m): 6,0 g/t Au | |||||||

| Including 75-76m (1m): 6,4 g/t Au | |||||||

| INES_20N | 26 | 28 | 2 | 1.03 | 9 | 117 | 1.13 |

| INES_21N | 40 | 42 | 2 | 1.06 | 5 | 38 | 1.12 |

| 44 | 46 | 2 | 1.08 | 10 | 50 | 1.19 | |

| 50 | 54 | 4 | 1.65 | 25 | 51 | 1.93 | |

| 56 | 59 | 3 | 1.22 | 13 | 84 | 1.37 | |

| INES_22N | 38 | 40 | 2 | 1.20 | 8 | 49 | 1.29 |

| 46 | 52 | 6 | 1.14 | 12 | 57 | 1.28 | |

| Drill hole | From (m) | To (m) | Length (m) | Au (g/t) | Ag (g/t) | Cu (g/t) | Au Eq (g/t) |

| INES_24N DDH | 52.1 | 52.5 | 0.4 | 12.05 | 126 | 130 | 13.47 |

| 53.75 | 61.77 | 8.02 | 1.45 | 13 | 51 | 1.59 | |

| 75 | 75.34 | 0.34 | 1.11 | 13 | 120 | 1.26 | |

| 122.85 | 134.8 | 11.95 | 2.66 | 41 | 11136 | 3.13 | |

| Including 123,47-124,44m (0,97m): 8,83 g/t Au | |||||||

| Including 127,31-139,11m (1,8m): 6,86 g/t Au | |||||||

| 149.45 | 150.8 | 1.35 | 2.16 | 21 | 16026 | 2.39 | |

| 153.43 | 155.1 | 1.67 | 1.04 | 20 | 10334 | 1.26 | |

| 180.52 | 181.32 | 0.8 | 3.08 | 9 | 2780 | 3.18 | |

| 184.37 | 186.44 | 2.07 | 1.48 | 14 | 6752 | 1.64 | |

| 188.17 | 190.12 | 1.95 | 1.94 | 36 | 2586 | 2.34 | |

| INES_26N | 39 | 40 | 1 | 1.47 | 56 | 141 | 2.10 |

| 44 | 45 | 1 | 4.45 | 21 | 102 | 4.69 | |

| 52 | 54 | 2 | 1.38 | 22 | 116 | 1.63 | |

| 56 | 60 | 4 | 1.55 | 25 | 68 | 1.83 | |

| INES_27N | 11 | 16 | 5 | 1.29 | 10 | 156 | 1.41 |

| 33 | 35 | 2 | 1.40 | 19 | 161 | 1.62 | |

| 63 | 79 | 16 | 2.29 | 12 | 107 | 2.42 | |

| Including 77-79m (2m): 6,64 g/t Au | |||||||

| 81 | 95 | 14 | 2.90 | 33 | 107 | 3.27 | |

| Including 84-85m (1m): 13,77 g/t Au | |||||||

| INES_28N | 24 | 28 | 4 | 1.92 | 6 | 98 | 1.99 |

| 31 | 38 | 7 | 2.04 | 6 | 65 | 2.11 | |

| 45 | 52 | 7 | 2.47 | 22 | 37 | 2.72 | |

| Including 46-47m (1m): 7,77 g/t Au | |||||||

| 56 | 57 | 1 | 1.66 | 19 | 71 | 1.88 | |

| INES_29N | 12 | 24 | 12 | 2.08 | 26 | 558 | 2.37 |

| Including 12-13m (1m): 8,30 g/t Au | |||||||

| 37 | 38 | 1 | 3.63 | 70 | 173 | 4.42 | |

| INES_31N | 14 | 15 | 1 | 1.60 | 9 | 142 | 1.70 |

| 17 | 20 | 3 | 1.61 | 7 | 83 | 1.69 | |

| 23 | 28 | 5 | 1.60 | 4 | 95 | 1.65 | |

| 32 | 36 | 4 | 1.15 | 3 | 90 | 1.18 | |

| 38 | 39 | 1 | 2.18 | 7 | 93 | 2.26 | |

| 42 | 43 | 1 | 1.62 | 22 | 79 | 1.87 | |

| INES_32N | 21 | 22 | 1 | 1.40 | 9 | 317 | 1.50 |

| 49 | 54 | 5 | 1.31 | 39 | 220 | 1.74 | |

| 56 | 57 | 1 | 1.07 | 10 | 287 | 1.19 | |

| INES_35N DDH | 42.6 | 45.58 | 2.98 | 1.12 | 16 | 94 | 1.30 |

| 56.95 | 61.03 | 4.08 | 1.85 | 35 | 190 | 2.25 | |

| 65.5 | 75.75 | 10.25 | 1.97 | 23 | 97 | 2.23 | |

| Drill hole | From (m) | To (m) | Length (m) | Au (g/t) | Ag (g/t) | Cu (g/t) | Au Eq (g/t) |

| INES_36N DDH | 25.78 | 27.45 | 1.67 | 2.35 | 4 | 40 | 2.40 |

| 36.45 | 38.6 | 2.15 | 1.27 | 4 | 20 | 1.31 | |

| 40.6 | 54 | 13.4 | 2.68 | 13 | 61 | 2.83 | |

| Including 40,6-42,6m (2m): 5,71 g/t Au | |||||||

| INES_37N | 38 | 39 | 1 | 1.03 | 30 | 49 | 1.37 |

| 47 | 54 | 7 | 1.60 | 3.6 | 74 | 1.64 | |

| INES_38N | 38 | 40 | 2 | 1.45 | 49 | 88 | 2.00 |

| 45 | 51 | 6 | 2.45 | 20 | 78 | 2.67 | |

| Including 48-49m (1m): 5,62 g/t Au | |||||||

| 53 | 64 | 11 | 1.54 | 4 | 92 | 1.59 | |

| 67 | 75 | 8 | 4.26 | 21 | 106 | 4.50 | |

| Including 67-68m (1m): 19,17 g/t Au | |||||||

| INES_40N | 22 | 24 | 2 | 1.76 | 41 | 346 | 2.22 |

| 34 | 37 | 3 | 2.12 | 29 | 104 | 2.45 | |

| 61 | 69 | 8 | 2.18 | 8 | 137 | 2.27 | |

| 76 | 79 | 3 | 3.42 | 75 | 135 | 4.26 | |

| Including 78-79m (1m): 6,90 g/t Au | |||||||

| 87 | 88 | 1 | 1.11 | 6 | 57 | 1.18 | |

| INES_41N | 45 | 48 | 3 | 1.88 | 8 | 210 | 1.97 |

| 50 | 51 | 1 | 1.92 | 10 | 210 | 2.04 | |

| 52 | 56 | 4 | 1.24 | 6 | 161 | 1.31 | |

| 59 | 65 | 6 | 1.71 | 8 | 96 | 1.80 | |

| INES_42N DDH | 44.4 | 47.5 | 3.1 | 1.05 | 4 | 114 | 1.10 |

| 58.8 | 68.1 | 9.3 | 1.27 | 25 | 163 | 1.55 | |

| 71.25 | 73.2 | 1.95 | 1.05 | 15 | 200 | 1.22 | |

| 75.05 | 82.6 | 7.55 | 2.08 | 16 | 171 | 2.26 | |

| Including 79,63-81m (1,37m): 5,48 g/t Au | |||||||

| 85.55 | 86.43 | 0.88 | 8.18 | 36 | 200 | 8.59 | |

| 88 | 89.74 | 1.74 | 1.91 | 8 | 83 | 2.00 | |

| 91.09 | 93.87 | 2.78 | 3.43 | 30 | 164 | 3.77 | |

| Including 92,65-93,2m (0,55m): 8,08 g/t Au | |||||||

| 97.68 | 101.73 | 4.05 | 3.99 | 22 | 163 | 4.24 | |

| Including 101,1-101,73m (0,63m): 13,80 g/t Au | |||||||

| 103.22 | 104.18 | 0.96 | 1.18 | 24 | 130 | 1.45 | |

| INES_43N | 2 | 3 | 1 | 1.72 | 2 | 37 | 1.74 |

| 22 | 24 | 2 | 3.62 | 13 | 263 | 3.76 | |

| Including 23-24m (1m): 5,57 g/t Au | |||||||

| 31 | 37 | 6 | 1.54 | 11 | 111 | 1.66 | |

| INES_44N | 39 | 41 | 2 | 1.35 | 22 | 174 | 1.60 |

| 46 | 50 | 4 | 1.19 | 14 | 104 | 1.35 | |

| INES_45N | 39 | 44 | 5 | 1.52 | 5 | 120 | 1.58 |

| Drill hole | From (m) | To (m) | Length (m) | Au (g/t) | Ag (g/t) | Cu (g/t) | Au Eq (g/t) |

| 114 | 115 | 1 | 4.10 | 49 | 47 | 4.65 | |

| 117 | 118 | 1 | 1.50 | 6 | 27 | 1.57 | |

| INES_47N | 126 | 127 | 1 | 2.12 | 32 | 113 | 2.48 |

| INES_48N | 25 | 27 | 2 | 3.99 | 11 | 138 | 4.12 |

| 35 | 36 | 1 | 1.61 | 16 | 65 | 1.79 | |

| INES_49N | 2 | 3 | 1 | 5.20 | 23 | 1921 | 5.46 |

| 9 | 11 | 2 | 2.20 | 46 | 370 | 2.72 | |

| 16 | 19 | 3 | 1.75 | 25 | 189 | 2.03 | |

| 23 | 24 | 1 | 1.96 | 13 | 212 | 2.11 | |

| 26 | 28 | 2 | 1.27 | 8 | 239 | 1.36 | |

| INES_50N DDH | 43.86 | 51.5 | 7.64 | 1.96 | 7 | 65 | 2.04 |

| 55.93 | 57.26 | 1.33 | 1.48 | 6 | 90 | 1.54 | |

| 60.52 | 61.96 | 1.44 | 1.47 | 8 | 80 | 1.56 | |

| 63.21 | 64.24 | 1.03 | 4.83 | 28 | 60 | 5.15 | |

| 71.6 | 90 | 18.4 | 1.63 | 11 | 99 | 1.75 | |

| Including 80,42-81,8m (1,38m): 6,22 g/t Au | |||||||

| 100.07 | 106.35 | 6.28 | 2.10 | 18 | 150 | 2.30 | |

| Including 100,88-102,15 (1,27m) : 2,32 g/t Au | |||||||

| Including 102,78-104,2 (1,42m) : 2,05 g/t Au | |||||||

| Including 104,95-106,35 (1,4m) : 3,17 g/t Au | |||||||

* Reporting Criteria: Intercepts reported are Au > 1.0ppm (1 g/t Au) and a minimum 1m downhole width with maximum consecutive internal dilution of 2m. Please refer to Appendix 1 (JORC Table) for further information on sampling techniques and data and reporting of exploration results.

The table above displays selected analytical results from a total of 48 RC and DDH drill holes. Complete drill results have been posted on the Company's website www.australgold.com.

Figure 2: Drilling holes with grade intervals of Au > 1.0ppm (1 g/t Au)

To view an enhanced version of Figure 2, please visit:

https://orders.newsfilecorp.com/files/690/51953_db87bae354d408f3_003full.jpg

Competent Persons

The scientific and technical content of this news release has been prepared by, or under the supervision of Robert Trzebski, MAusIMM , and has been reviewed and approved by him. Dr. Trzebski is a Geologist and Member of Australian Institute of Mining and Metallugists and Director of Austral Gold Limited. Dr. Trzebski is a "competent person" for purposes of the JORC Code and of National Instrument 43-101, Standards of Disclosure for Mineral Projects.

About Austral Gold

Austral Gold Limited is a growing precious metals mining, development and exploration company building a portfolio of quality assets in Chile and Argentina. The Company's flagship Guanaco/Amancaya project in Chile is a gold and silver producing mine with further exploration upside. The company also holds the Casposo Mine (San Juan, Argentina), a ~22.48% interest in the Rawhide Mine (Nevada, USA) and an attractive portfolio of exploration projects including the Pingüino project in Santa Cruz, Argentina (100% interest) and the San Guillermo and Reprado projects near Amancaya (100% interest). With an experienced local technical team and highly regarded major shareholder, Austral's goal is to continue to strengthen its asset base through acquisition and discovery. Austral Gold Limited is listed on the TSX Venture Exchange (TSXV: AGLD), and the Australian Securities Exchange. (ASX: AGD). For more information, please consult the company's website www.australgold.com.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

On behalf of Austral Gold Limited:

"Stabro Kasaneva"

CEO

For Further Information please contact:

Jose Bordogna

Chief Financial Officer

Austral Gold Limited

jose.bordogna@australgold.com

54 11 4323 7558

David Hwang

Company Secretary

Austral Gold Limited

info@australgold.com

61 2 9698 5414

Forward Looking Statements

Statements in this news release that are not historical facts are forward-looking statements. Forward-looking statements are statements that are not historical, and consist primarily of projections - statements regarding future plans, expectations and developments. Words such as "expects", "intends", "plans", "may", "could", "potential", "should", "anticipates", "likely", "believes" and words of similar import tend to identify forward-looking statements. Forward-looking statements in this news release include the Company's plan to review and analyze the results as it plans its next drill program, metallurgical testing, a geophysics campaign at Sierra Inesperada, and the Company's anticipation that the geological characteristics and orientation of the structural patterns will provide an important exploration guide to the geological potential at Sierra Inesperada.

All of these forward-looking statements are subject to a variety of known and unknown risks, uncertainties and other factors that could cause actual events or results to differ from those expressed or implied, including, without limitation, business integration risks; uncertainty of production, development plans and cost estimates, commodity price fluctuations; political or economic instability and regulatory changes; currency fluctuations, the state of the capital markets, uncertainty in the measurement of mineral reserves and resource estimates, Austral's ability to attract and retain qualified personnel and management, potential labour unrest, reclamation and closure requirements for mineral properties; unpredictable risks and hazards related to the development and operation of a mine or mineral property that are beyond the Company's control, the availability of capital to fund all of the Company's projects and other risks and uncertainties identified under the heading "Risk Factors" in the Company's continuous disclosure documents filed on the ASX and on SEDAR. You are cautioned that the foregoing list is not exhaustive of all factors and assumptions which may have been used. Austral cannot assure you that actual events, performance or results will be consistent with these forward-looking statements, and management's assumptions may prove to be incorrect. Austral's forward-looking statements reflect current expectations regarding future events and operating performance and speak only as of the date hereof and Austral does not assume any obligation to update forward-looking statements if circumstances or management's beliefs, expectations or opinions should change other than as required by applicable law. For the reasons set forth above, you should not place undue reliance on forward-looking statements.

Appendix 1: JORC Table

Sierra Inesperada Exploration

Section 1 Sampling Techniques and Data

(Criteria in this section apply to all succeeding sections.)

| Criteria | JORC Code Explanation | Commentary |

| Sampling techniques |

|

|

| Drilling techniques |

|

|

| Criteria | JORC Code Explanation | Commentary |

| Drill sample recovery |

|

|

| Logging |

|

|

| Sub- sampling techniques and sample preparation |

|

|

| Criteria | JORC Code Explanation | Commentary |

| Quality of assay data and laboratory tests |

|

|

| Verification of sampling and assaying |

|

|

| Location of data points |

|

|

| Data spacing and distribution |

|

|

| Criteria | JORC Code Explanation | Commentary |

| Orientation of data in relation to geological structure |

|

|

| Sample security |

|

|

| Audits or reviews |

|

|

Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this section)

| Criteria | JORC Code Explanation | Commentary |

| Mineral tenement and land tenure status |

|

|

| Criteria | JORC Code Explanation | Commentary |

| Exploration done by other parties |

|

|

| Geology |

|

|

| Drill hole Information |

|

|

| Criteria | JORC Code Explanation | Commentary |

| Data aggregation methods |

|

|

| Relationship between mineralisation widths and intercept lengths |

|

|

| Diagrams |

|

|

| Balanced reporting |

|

|

| Criteria | JORC Code Explanation | Commentary |

| Other substantive exploration data |

|

|

| Further work |

|

|

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/51953

Source: Austral Gold Limited