HIGHLIGHTS:

Pre-tax net present value ("NPV") of $1.747 billion and Internal Rate of Return ("IRR") of 42% and an after-tax NPV of $1.034 billion and IRR of 32% at an 8% discount rate, assuming long-term prices of US$49.59 per kilogram ("kg") or US$22.50 per pound ("lb") of molybdenum ("Mo"); US$8.93 per kg or US$4.06 per lb. of copper ("Cu") and US$300 per metric tonne unit ("MTU") or US$13.60 per lb of tungsten ("W"); and a CAD:US dollar exchange rate of $0.74;

20-year mine life based on 10,000 tonnes of mill throughput per day or 3.65 million tonnes per year;

Initial capital cost of $672.3 million including $106.3 million of contingency;

Annual average production of 6,020,000 kg or 13,243,000 pounds of Mo; 679,600 kg or 1,498,500 lbs of Cu and 151.7 tonnes or 334,300 lbs of W;

Average cash cost of $22.11 per kg or $10.03 per lb of Mo and All-In Sustaining Cost ("AISC") of $22.80 per kg or $10.34 per lb of Mo, net of Cu and W production credits;

Underground mine, with underground processing facilities, using primarily battery powered mining equipment minimizes the surface footprint, resulting in a very low carbon emitting operation;

A measured and indicated ("M & I") mineral resource of 80,756,000 tonnes grading 0.304% MoS2 (0.182% Mo) and 0.037% Cu and an inferred ('inferred") mineral resource of 83,100,000 tonnes grading 0.036% WO3;

A 2.3-year payback;

Life-of-mine direct income and mining taxes in excess of $1.743 billion; and

The break-even cut-off grade for the mine, excluding credits from copper and tungsten revenue, is 0.11% MoS2. This results in a potentially mineable M&I MoS2 and Cu resource, in excess of 436 million tonnes for a potential mine life of ~120 years. For the purposes of the updated Preliminary Economic Assessment ("PEA"), a cut-off grade of 0.22% MoS2 was used and this would give the Project a 20-year mine life.

All dollar amounts are stated in Canadian Dollars unless otherwise noted.

Toronto, Ontario--(Newsfile Corp. - December 23, 2025) - Moon River Moly Ltd. (TSXV: MOO) (OTCQB: MRIVF) ("Moon River" or the "Company") is pleased to announce that an updated PEA has been completed on the Davidson Molybdenum-Copper-Tungsten-Project (the "Project" or "Davidson Property") located near Smithers, British Columbia.

Paul Parisotto, President and Chief Executive Officer, says of the updated PEA results: "We are very encouraged from the results of the updated PEA. The major differences between the initial PEA issued in February 2024, and this updated PEA are an increase in daily production from 7,000 tonnes per day to 10,000 tonnes per day and the inclusion of revenue from tungsten and copper production. Additionally, the potential to increase the mine life to more than 100 years is very positive."

Ian McDonald, Chairman, went on to state: "My involvement with this Project first began over twenty years ago, and I truly believe that the time for its development has arrived. These robust economics together with its location in a Tier One jurisdiction in a mining-friendly province, to produce products that are included on Canada's 2021 Critical Mineral List, near developed infrastructure, including roads, rail, power, and the nearby town of Smithers are definite benefits. Additionally, to be able to take advantage of the province's hydro-electric power grid, allows for the use of an efficient electric mining fleet, and will make the Davidson Property one of the lowest carbon-emitting sources of molybdenum in the world. As an underground mine, with an underground processing plant and with most of the tailings used as backfill, the surface footprint of this mining operation will be minimized."

The updated PEA was prepared by A-Z Mining Professionals Ltd. ("AMPL") for Moon River. The Project, located in west central British Columbia, is approximately nine kilometres ("km") northwest of the town of Smithers. On November 15, 2023, Moon River acquired all of the rights, interests and obligations of Generation Mining Ltd. under a vending agreement dated April 1, 2016, as amended, entered into with Roda Holdings Inc. and Mr. Donald Davidson, thus granting Moon River the exclusive right to access, prospect, develop and mine the Davidson Property and to acquire 100% of the Davidson Property. The Project comprises development of an underground mine with potentially economic mineralization processed in an underground, on-site processing facility, with an estimated 20-year mine life.

PROJECT DESIGN

The Davidson Deposit is located inside Hudson Bay Mountain and does not outcrop on surface. The deposit has an existing portal on the east side of the mountain and over 2,100 metres ("m") of exploration drifting. The access road and portal can be seen from the town of Smithers. The proposed underground mine access and surface facilities will be located on the west side of the mountain (out of sight of the town of Smithers) with the existing eastern portal used only for initial development.

To minimise the surface footprint of the whole operation, the processing plant will be located underground in specially designed and excavated openings at the top elevation of the mining zones. This eliminates having to move mineralized material from the underground to a surface processing plant 8 km away. This also eliminates material for processing being trucked to surface and the need for a source of backfill material from surface as well. The mill tailings will provide a ready source of material for backfilling mined areas and significantly reduces the size of the tailings management facility on surface. Additionally, the incorporation of dry stacked tailings eliminates need for a traditional hydraulic tailings storage facility.

The mine will utilise already proven rubber-tired, battery-powered and automated mining equipment wherever possible to minimize manpower requirements, underground ventilation volumes, mine air heating costs and CO2 emissions.

Surface infrastructure required would include:

- Upgrading of access road

- Powerline construction

- Electrical substations and distribution

- Site roads and materials handling area

- Maintenance shop/offices/dry/warehouse complex (temporary)

- Two cement storage silos

- Water supply system and water treatment plant

- Dry stack tailings dewatering plant and impoundment area

- Development waste storage

- Landfill site

- Sewage disposal site

The mine will employ 238 persons once in full operation. During pre-production, a contractor workforce will be employed. There is a history of mining in the region and many skilled workers in the area currently work from Smithers that has a population of 5,400 people and many support services.

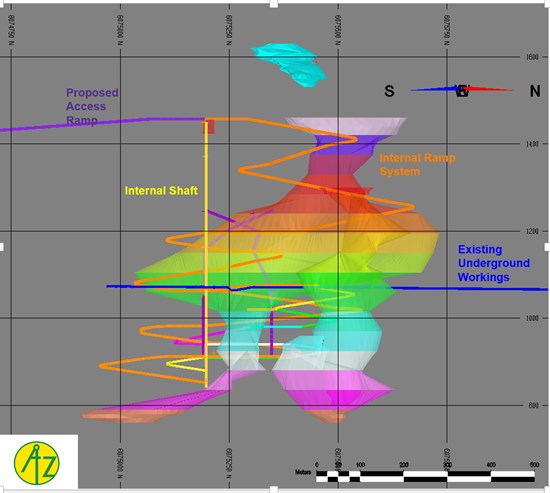

MINE PLAN

Underground mining methods will be utilised to extract the potentially economic mineralization of the deposit. An underground internal ramp from the bottom to the top of the mining zone will access mining areas and the underground processing plant facility. In total, some 36,000 m of pre-production development will be required to bring the deposit into production.

The mining method to be employed would be Longhole Open Stoping with cemented paste (densified tailings) backfill to maximise recovery of potentially economic mineralization. Dilution of 5% has been included in the mined potentially economic mineralization at a grade of 0.20% MoS2.

The mineralized zone is large and irregular shaped, with higher grade concentrations towards the centre of the mineralized zones being mined. The mine would produce 10,000 tonnes per day of potentially economic mineralization. The mineralized zone geometry is highly amenable to bulk mining of large tonnage stopes with inherent economies of scale and low mining costs. The stopes will be approximately 160,000 tonnes each.

Figure 1 Underground Mine Design

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/7009/278892_6d9fac0cd4fac82b_001full.jpg

Potentially economic mineralization removed from stopes by load-haul-dump (LHD) units will be sent by ore passes to jaw crushers at the bottom of the mine, to a coarse ore bin and then to secondary and tertiary cone crushers below the coarse ore bin. The crushed potentially economic mineralisation will be conveyed to a vertical lift conveyor system which feeds the fine ore bin connected to the underground processing facility.

Other underground facilities will include:

- Paste backfill plant

- Equipment maintenance shops and underground warehouses

- Explosives storage magazines

- Refuge stations

- Fuel bays

- Materials storage areas

- Main dewatering sumps

- Offices

- Warehousing facilities

PROCESSING

The processing plant, located completely underground, will be a conventional flotation plant producing molybdenum, tungsten and copper concentrates for shipment to smelters.

The potentially economic mineralization from the fine ore bin will feed two grinding lines, each consisting of one rod mill, one ball mill, and a set of cyclones for classification. Each grinding line cyclone overflow stream will feed a dedicated molybdenum rougher flotation line using tank cells, with rougher concentrate advancing to molybdenum cleaning and tails continuing to pyrite flotation.

Molybdenum rougher concentrate will be cleaned in a circuit using four stages of column flotation and one stage of stirred-mill regrinding to produce a final concentrate. The molybdenum final concentrate stream will be thickened, filtered, dried, and packaged for shipment to a smelter while first cleaner tails molybdenum values will be scavenged in tank cells.

Byproduct copper will be recovered from the molybdenum cleaner scavenger flotation tails stream using tank cells for copper rougher flotation and a column cell for cleaning. Copper rougher tails will report to the final tailings thickener, while copper concentrate will be thickened and filtered prior to shipment to a smelter.

Pyrite flotation will be used to prepare molybdenum rougher flotation tails for tungsten recovery, with flotation occurring in tank cells. The pyrite flotation concentrate will report to the final tails thickener, while the remaining desulphurised tailings will report to batch centrifugal gravity concentrators for recovery of scheelite. The concentrate from the centrifuges will be sorted into fine and coarse fractions using high-frequency slurry screens, with each stream feeding a dedicated set of shaking tables for cleaning. Tungsten concentrate will be filtered and packaged for shipment to a refinery, while tungsten tailings will report to the final tailings thickener.

The tailings thickener underflow will be primarily made into paste backfill for backfilling of stopes, with the balance pumped to a dry stack tailings facility on surface. At the dry stack tailings facility, the tailings will be filtered for water removal, with the filter product being stacked in a near dry form for permanent storage and the water removed being sent to surface storage pond for re-use in the processing plant.

The processing plant is expected to have a recovery rate of 94.4% molybdenum, 52.4% copper and 15.5% tungsten into concentrate.

The proposed processing plant will be arranged to fit in a long room. Grinding mills will be located at one end of the room, with grinding cyclone overflow gravitating to molybdenum rougher flotation and subsequently through pyrite flotation. The molybdenum cleaner flotation and byproduct recovery circuits will be located at the opposite end of the room from the grinding circuits. The construction cost of an underground plant is not significantly different from that for a plant located on surface.

MINERAL RESOURCES

The data used to generate the resource calculation was reviewed and approved by F. Bakker P.Geo. This included a site visit by Mr. Bakker (July 30, 2024, to August 26, 2024). Sampling methods, QAQC programs and databases were examined. In addition, he supervised a diamond drill program that was used to gather metallurgical samples. Mr. Bakker is of the opinion that the accuracy of the data was sufficient for a mineral resource statement.

The mineral resource was calculated utilizing commercial 3D Block Modelling Software (HxGN Mine Plantm 3D). For the current mineral resource estimate, a mineralized solid was constructed around a roughly designed and manually constrained 0.1% MoS2 grade shell to constrain the estimate. In addition, the model utilized geostatistics (variograms) to better confine mineralized limits. This resource model was used for determining the mineral resources estimate and to undertake an underground mine production plan.

The effective date of the mineral resource is December 23, 2025, the date of this news release.

Mr. Bakker is unaware of any known legal, political, environmental, or other risks that could materially affect the potential development of the mineral resources or mineral reserves.

With the exception of tungsten, inferred mineral resources were not included in the PEA economic analysis. The PEA is preliminary in nature and includes inferred mineral resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves. There is no certainty that the PEA will be realized.

The following tables present the mineral resource estimate for the Davidson Property at various cut-off grades.

The mineral resource estimate has been recalculated to include both copper and tungsten values in the Davidson Property and is included in the updated PEA.

| TABLE 1: MEASURED MINERAL RESOURCES for MoS2 and Copper | |||||||

| Category | Cut-off Grade %MoS2 | Tonnes | Grade MoS2 | Grade %Mo | Grade %Cu | Contained Mo kg | Contained Cu kg |

| Measured | >0.100 | 128,457,000 | 0.203 | 0.122 | 0.036 | 156,354,000 | 46,630,000 |

| Measured | >0.110 | 118,655,000 | 0.211 | 0.127 | 0.037 | 150,180,000 | 43,546,000 |

| Measured | >0.120 | 107,899,000 | 0.221 | 0.132 | 0.037 | 142,836,000 | 40,138,000 |

| Measured | >0.130 | 97,680,000 | 0.231 | 0.138 | 0.038 | 135,217,000 | 36,923,000 |

| Measured | >0.140 | 88,115,000 | 0.242 | 0.145 | 0.039 | 127,519,000 | 33,924,000 |

| Measured | >0.150 | 79,982,000 | 0.251 | 0.151 | 0.039 | 120,444,000 | 31,193,000 |

| Measured | >0.160 | 72,442,000 | 0.262 | 0.157 | 0.039 | 113,472,000 | 28,470,000 |

| Measured | >0.170 | 65,205,000 | 0.272 | 0.163 | 0.040 | 106,354,000 | 25,821,000 |

| Measured | >0.180 | 58,803,000 | 0.283 | 0.170 | 0.040 | 99,681,000 | 23,462,000 |

| Measured | >0.190 | 53,103,000 | 0.294 | 0.176 | 0.040 | 93,390,000 | 21,294,000 |

| Measured | >0.200 | 47,928,000 | 0.304 | 0.182 | 0.040 | 87,361,000 | 19,315,000 |

| Measured | >0.210 | 42,771,000 | 0.316 | 0.189 | 0.041 | 81,036,000 | 17,322,000 |

| Measured | >0.220 | 38,418,000 | 0.328 | 0.196 | 0.041 | 75,458,000 | 15,559,000 |

| Measured | >0.230 | 34,406,000 | 0.340 | 0.204 | 0.041 | 70,051,000 | 13,969,000 |

| Measured | >0.240 | 30,973,000 | 0.352 | 0.211 | 0.041 | 65,232,000 | 12,606,000 |

| Measured | >0.250 | 27,866,000 | 0.364 | 0.218 | 0.041 | 60,691,000 | 11,369,000 |

| Measured | >0.260 | 25,079,000 | 0.376 | 0.225 | 0.041 | 56,439,000 | 10,232,000 |

| Measured | >0.270 | 22,584,000 | 0.388 | 0.232 | 0.041 | 52,488,000 | 9,192,000 |

| Measured | >0.280 | 20,417,000 | 0.400 | 0.240 | 0.041 | 48,931,000 | 8,310,000 |

| Measured | >0.290 | 18,456,000 | 0.412 | 0.247 | 0.041 | 45,591,000 | 7,512,000 |

| Measured | >0.300 | 16,786,000 | 0.424 | 0.254 | 0.041 | 42,642,000 | 6,798,000 |

| Measured | >0.310 | 15,242,000 | 0.436 | 0.261 | 0.040 | 39,825,000 | 6,143,000 |

| Measured | >0.320 | 13,869,000 | 0.448 | 0.269 | 0.040 | 37,243,000 | 5,575,000 |

- Mineral Resources were estimated using the CIM Standards on Mineral Resources and Reserves, Definitions and Guidelines prepared by the CIM Standing Committee on Reserve Definitions and adopted by the CIM Council.

- Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

- The PEA mine plan and economic model include numerous assumptions and the use of Inferred Resources. Inferred Resources are considered to be too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves and to be used in an economic analysis except as allowed for by NI 43-101 in PEA studies. There is no guarantee that Inferred Resources can be converted to Indicated or Measured Resources, and as such, there is no guarantee the economics described herein will be achieved.

- The estimate of Mineral Resources may be materially affected by environmental, permitting, legal, marketing, or other relevant issues.

- The approximate 3-year trailing average (to November 30, 2025) metal price for molybdenum of US$49.59 per kg or US$22.50 (rounded down) per lb),US$300 per MTU or US$13.60 per pound W, and US$8.93 per kg or US$4.06 per pound Cu was used in estimating the Mineral Resources and a CAD:US Dollar exchange rate of $0.74 was used.

- A description of the key assumptions, parameters, and methods used to estimate the resources, and any known risks, as well as the data verification processes, will be contained in this Technical Report.

| TABLE 2: INDICATED MINERAL RESOURCES for MoS2 and Copper | |||||||

| Category | Cut-off Grade %MoS2 | Tonnes | Grade Mo S2 | Grade %Mo | Grade %Cu | Contained Mo kg | Contained Cu kg |

| Indicated | >0.100 | 360,595,000 | 0.159 | 0.095 | 0.028 | 343,434,000 | 102,048,000 |

| Indicated | >0.110 | 317,987,000 | 0.166 | 0.100 | 0.029 | 316,568,000 | 90,626,000 |

| Indicated | >0.120 | 270,065,000 | 0.176 | 0.105 | 0.029 | 283,904,000 | 79,129,000 |

| Indicated | >0.130 | 229,447,000 | 0.185 | 0.111 | 0.030 | 253,574,000 | 68,146,000 |

| Indicated | >0.140 | 192,639,000 | 0.194 | 0.116 | 0.030 | 223,858,000 | 58,177,000 |

| Indicated | >0.150 | 158,417,000 | 0.205 | 0.123 | 0.031 | 194,338,000 | 48,476,000 |

| Indicated | >0.160 | 130,259,000 | 0.216 | 0.129 | 0.031 | 168,300,000 | 40,250,000 |

| Indicated | >0.170 | 107,639,000 | 0.227 | 0.136 | 0.031 | 146,038,000 | 33,691,000 |

| Indicated | >0.180 | 88,553,000 | 0.238 | 0.142 | 0.031 | 126,084,000 | 27,806,000 |

| Indicated | >0.190 | 72,355,000 | 0.250 | 0.150 | 0.032 | 108,222,000 | 23,009,000 |

| Indicated | >0.200 | 60,443,000 | 0.261 | 0.156 | 0.032 | 94,351,000 | 19,281,000 |

| Indicated | >0.210 | 50,863,000 | 0.271 | 0.162 | 0.032 | 82,626,000 | 16,429,000 |

| Indicated | >0.220 | 42,338,000 | 0.283 | 0.169 | 0.033 | 71,694,000 | 13,929,000 |

| Indicated | >0.230 | 35,902,000 | 0.293 | 0.176 | 0.033 | 63,032,000 | 11,884,000 |

| Indicated | >0.240 | 30,579,000 | 0.303 | 0.182 | 0.033 | 55,573,000 | 9,938,000 |

| Indicated | >0.250 | 26,202,000 | 0.313 | 0.188 | 0.032 | 49,172,000 | 8,463,000 |

| Indicated | >0.260 | 22,474,000 | 0.323 | 0.193 | 0.032 | 43,482,000 | 7,192,000 |

| Indicated | >0.270 | 18,572,000 | 0.335 | 0.201 | 0.033 | 37,301,000 | 6,073,000 |

| Indicated | >0.280 | 15,548,000 | 0.347 | 0.208 | 0.033 | 32,326,000 | 5,177,000 |

| Indicated | >0.290 | 12,867,000 | 0.360 | 0.216 | 0.035 | 27,762,000 | 4,452,000 |

| Indicated | >0.300 | 10,932,000 | 0.372 | 0.223 | 0.035 | 24,353,000 | 3,837,000 |

| Indicated | >0.310 | 9,292,000 | 0.384 | 0.230 | 0.035 | 21,362,000 | 3,289,000 |

| Indicated | >0.320 | 8,123,000 | 0.394 | 0.236 | 0.036 | 19,161,000 | 2,884,000 |

- Mineral Resources were estimated using the CIM Standards on Mineral Resources and Reserves, Definitions and Guidelines prepared by the CIM Standing Committee on Reserve Definitions and adopted by the CIM Council.

- Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

- The PEA mine plan and economic model include numerous assumptions and the use of Inferred Resources. Inferred Resources are considered to be too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves and to be used in an economic analysis except as allowed for by NI 43-101 in PEA studies. There is no guarantee that Inferred Resources can be converted to Indicated or Measured Resources, and as such, there is no guarantee the economics described herein will be achieved.

- The estimate of Mineral Resources may be materially affected by environmental, permitting, legal, marketing, or other relevant issues.

- The approximate 3-year trailing average (to November 30, 2025) metal price for molybdenum of US$49.59 per kg or US$22.50 (rounded down) per lb),US$300 per MTU or US$13.60 per pound W, and US$8.93 per kg or US$4.06 per pound Cu was used in estimating the Mineral Resources and a CAD:US Dollar exchange rate of $0.74 was used.

- A description of the key assumptions, parameters, and methods used to estimate the resources, and any known risks, as well as the data verification processes, will be contained in the Technical Report.

| TABLE 3: MEASURED + INDICATED MINERAL RESOURCES for MoS2 and Copper | |||||||

| Category | Cut-off Grade %MoS2 | Tonnes | Grade MoS2 | Grade %Mo | Grade %Cu | Contained Mo kg | Contained Cu kg |

| Measured + Indicated | >0.100 | 489,053,000 | 0.171 | 0.102 | 0.030 | 499,789,000 | 148,679,000 |

| Measured + Indicated | >0.110 | 436,642,000 | 0.178 | 0.107 | 0.031 | 466,748,000 | 134,173,000 |

| Measured + Indicated | >0.120 | 377,964,000 | 0.188 | 0.113 | 0.032 | 426,740,000 | 119,267,000 |

| Measured + Indicated | >0.130 | 327,127,000 | 0.198 | 0.119 | 0.032 | 388,792,000 | 105,069,000 |

| Measured + Indicated | >0.140 | 280,754,000 | 0.209 | 0.125 | 0.033 | 351,377,000 | 92,101,000 |

| Measured + Indicated | >0.150 | 238,399,000 | 0.220 | 0.132 | 0.033 | 314,782,000 | 79,669,000 |

| Measured + Indicated | >0.160 | 202,701,000 | 0.232 | 0.139 | 0.034 | 281,772,000 | 68,720,000 |

| Measured + Indicated | >0.170 | 172,844,000 | 0.244 | 0.146 | 0.034 | 252,392,000 | 59,512,000 |

| Measured + Indicated | >0.180 | 147,356,000 | 0.256 | 0.153 | 0.035 | 225,765,000 | 51,268,000 |

| Measured + Indicated | >0.190 | 125,459,000 | 0.268 | 0.161 | 0.035 | 201,614,000 | 44,304,000 |

| Measured + Indicated | >0.200 | 108,371,000 | 0.280 | 0.168 | 0.036 | 181,712,000 | 38,596,000 |

| Measured + Indicated | >0.210 | 93,634,000 | 0.292 | 0.175 | 0.036 | 163,662,000 | 33,751,000 |

| Measured + Indicated | >0.220 | 80,756,000 | 0.304 | 0.182 | 0.037 | 147,152,000 | 29,489,000 |

| Measured + Indicated | >0.230 | 70,308,000 | 0.316 | 0.189 | 0.037 | 133,083,000 | 25,852,000 |

| Measured + Indicated | >0.240 | 61,552,000 | 0.328 | 0.196 | 0.037 | 120,805,000 | 22,544,000 |

| Measured + Indicated | >0.250 | 54,068,000 | 0.339 | 0.203 | 0.037 | 109,864,000 | 19,833,000 |

| Measured + Indicated | >0.260 | 47,554,000 | 0.351 | 0.210 | 0.037 | 99,923,000 | 17,424,000 |

| Measured + Indicated | >0.270 | 41,156,000 | 0.364 | 0.218 | 0.037 | 89,789,000 | 15,265,000 |

| Measured + Indicated | >0.280 | 35,965,000 | 0.377 | 0.226 | 0.038 | 81,258,000 | 13,487,000 |

| Measured + Indicated | >0.290 | 31,323,000 | 0.391 | 0.234 | 0.038 | 73,353,000 | 11,964,000 |

| Measured + Indicated | >0.300 | 27,718,000 | 0.404 | 0.242 | 0.038 | 66,996,000 | 10,635,000 |

| Measured + Indicated | >0.310 | 24,534,000 | 0.416 | 0.249 | 0.038 | 61,187,000 | 9,432,000 |

| Measured + Indicated | >0.320 | 21,992,000 | 0.428 | 0.256 | 0.038 | 56,404,000 | 8,459,000 |

- Mineral Resources were estimated using the CIM Standards on Mineral Resources and Reserves, Definitions and Guidelines prepared by the CIM Standing Committee on Reserve Definitions and adopted by the CIM Council.

- Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

- The PEA mine plan and economic model include numerous assumptions and the use of Inferred Resources. Inferred Resources are considered to be too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves and to be used in an economic analysis except as allowed for by NI 43-101 in PEA studies. There is no guarantee that Inferred Resources can be converted to Indicated or Measured Resources, and as such, there is no guarantee the economics described herein will be achieved.

- The estimate of Mineral Resources may be materially affected by environmental, permitting, legal, marketing, or other relevant issues.

- The approximate 3-year trailing average (to November 30, 2025) metal price for molybdenum of US$49.59 per kg or US$22.50 (rounded down) per lb),US$300 per MTU or US$13.60 per pound W, and US$8.93 per kg or US$4.06 per pound Cu was used in estimating the Mineral Resources and a CAD:US Dollar exchange rate of $0.74 was used.

- A description of the key assumptions, parameters, and methods used to estimate the resources, and any known risks, as well as the data verification processes, will be contained in this Technical Report.

| TABLE 4: INFERRED RESOURCES for MoS2 and Copper | |||||||

| Category | Cut-off Grade %MoS2 | Tonnes | Grade MoS2 | Grade %Mo | Grade %Cu | Contained Mo kg | Contained Cu kg |

| Inferred | >0.100 | 29,114,000 | 0.1504 | 0.0900896 | 0.0213 | 26,229,000 | 6,201,000 |

| Inferred | >0.110 | 24,995,000 | 0.158 | 0.094642 | 0.0204 | 23,656,000 | 5,099,000 |

| Inferred | >0.120 | 20,359,000 | 0.1679 | 0.1005721 | 0.0202 | 20,475,000 | 4,113,000 |

| Inferred | >0.130 | 16,734,000 | 0.1773 | 0.1062027 | 0.0196 | 17,772,000 | 3,280,000 |

| Inferred | >0.140 | 14,233,000 | 0.185 | 0.110815 | 0.0193 | 15,772,000 | 2,747,000 |

| Inferred | >0.150 | 11,574,000 | 0.1943 | 0.1163857 | 0.019 | 13,470,000 | 2,199,000 |

| Inferred | >0.160 | 9,094,000 | 0.2052 | 0.1229148 | 0.0176 | 11,178,000 | 1,601,000 |

| Inferred | >0.170 | 7,257,000 | 0.2156 | 0.1291444 | 0.0172 | 9,372,000 | 1,248,000 |

| Inferred | >0.180 | 6,059,000 | 0.2237 | 0.1339963 | 0.0154 | 8,119,000 | 933,000 |

| Inferred | >0.190 | 4,873,000 | 0.2334 | 0.1398066 | 0.0141 | 6,813,000 | 687,000 |

| Inferred | >0.200 | 3,494,000 | 0.2484 | 0.1487916 | 0.0126 | 5,199,000 | 440,000 |

| Inferred | >0.210 | 2,861,000 | 0.2583 | 0.1547217 | 0.0132 | 4,427,000 | 378,000 |

| Inferred | >0.220 | 2,444,000 | 0.2657 | 0.1591543 | 0.0131 | 3,890,000 | 320,000 |

| Inferred | >0.230 | 2,037,000 | 0.2736 | 0.1638864 | 0.0141 | 3,338,000 | 287,000 |

| Inferred | >0.240 | 1,725,000 | 0.2813 | 0.1684987 | 0.0144 | 2,907,000 | 248,000 |

| Inferred | >0.250 | 1,591,000 | 0.2845 | 0.1704155 | 0.0134 | 2,711,000 | 213,000 |

| Inferred | >0.260 | 1,447,000 | 0.2873 | 0.1720927 | 0.0129 | 2,490,000 | 187,000 |

| Inferred | >0.270 | 1,072,000 | 0.2952 | 0.1768248 | 0.0144 | 1,896,000 | 154,000 |

| Inferred | >0.280 | 477,000 | 0.3209 | 0.1922191 | 0.0179 | 917,000 | 85,000 |

| Inferred | >0.290 | 357,000 | 0.3337 | 0.1998863 | 0.0156 | 714,000 | 56,000 |

| Inferred | >0.300 | 246,000 | 0.3522 | 0.2109678 | 0.0218 | 519,000 | 54,000 |

| Inferred | >0.310 | 190,000 | 0.3663 | 0.2194137 | 0.0249 | 417,000 | 47,000 |

| Inferred | >0.320 | 180,000 | 0.3693 | 0.2212107 | 0.0237 | 398,000 | 43,000 |

- Mineral Resources were estimated using the CIM Standards on Mineral Resources and Reserves, Definitions and Guidelines prepared by the CIM Standing Committee on Reserve Definitions and adopted by the CIM Council.

- Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

- The PEA mine plan and economic model include numerous assumptions and the use of Inferred Resources. Inferred Resources are considered to be too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves and to be used in an economic analysis except as allowed for by NI 43-101 in PEA studies. There is no guarantee that Inferred Resources can be converted to Indicated or Measured Resources, and as such, there is no guarantee the economics described herein will be achieved.

- The estimate of Mineral Resources may be materially affected by environmental, permitting, legal, marketing, or other relevant issues.

- The approximate 3-year trailing average (to November 30, 2025) metal price for molybdenum of US$49.59 per kg or US$22.50 (rounded down) per lb),US$300 per MTU or US$13.60 per pound W, and US$8.93 per kg or US$4.06 per pound Cu was used in estimating the Mineral Resources and a CAD:US Dollar exchange rate of $0.74 was used.

- A description of the key assumptions, parameters, and methods used to estimate the resources, and any known risks, as well as the data verification processes, will be contained in this Technical Report.

| TABLE 5: INFERRED RESOURCES for WO3 | ||||

| Category | Cut-off Grade %MoS2 | Tonnes | Grade % WO3 | Contained WO3 kg |

| Inferred | >0.100 | 518,167,000 | 0.02988995 | 154,880,000 |

| Inferred | >0.110 | 461,637,000 | 0.03016908 | 139,272,000 |

| Inferred | >0.120 | 398,323,000 | 0.03097485 | 123,380,000 |

| Inferred | >0.130 | 343,861,000 | 0.03150943 | 108,349,000 |

| Inferred | >0.140 | 294,987,000 | 0.03215335 | 94,848,000 |

| Inferred | >0.150 | 249,973,000 | 0.03275059 | 81,868,000 |

| Inferred | >0.160 | 211,795,000 | 0.03320204 | 70,320,000 |

| Inferred | >0.170 | 180,101,000 | 0.03373683 | 60,760,000 |

| Inferred | >0.180 | 153,415,000 | 0.03402611 | 52,201,000 |

| Inferred | >0.190 | 130,332,000 | 0.03452003 | 44,991,000 |

| Inferred | >0.200 | 111,865,000 | 0.03489613 | 39,037,000 |

| Inferred | >0.210 | 96,495,000 | 0.03536832 | 34,129,000 |

| Inferred | >0.220 | 83,200,000 | 0.03582775 | 29,809,000 |

| Inferred | >0.230 | 72,345,000 | 0.03613186 | 26,140,000 |

| Inferred | >0.240 | 63,277,000 | 0.03602033 | 22,793,000 |

| Inferred | >0.250 | 55,659,000 | 0.03601538 | 20,046,000 |

| Inferred | >0.260 | 49,001,000 | 0.03593993 | 17,611,000 |

| Inferred | >0.270 | 42,228,000 | 0.03651392 | 15,419,000 |

| Inferred | >0.280 | 36,442,000 | 0.03724434 | 13,573,000 |

| Inferred | >0.290 | 31,680,000 | 0.03793953 | 12,019,000 |

| Inferred | >0.300 | 27,964,000 | 0.03822455 | 10,689,000 |

| Inferred | >0.310 | 24,724,000 | 0.03834011 | 9,479,000 |

| Inferred | >0.320 | 22,172,000 | 0.03834406 | 8,502,000 |

- Mineral Resources were estimated using the CIM Standards on Mineral Resources and Reserves, Definitions and Guidelines prepared by the CIM Standing Committee on Reserve Definitions and adopted by the CIM Council.

- Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

- The PEA mine plan and economic model include numerous assumptions and the use of Inferred Resources. Inferred Resources are considered to be too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves and to be used in an economic analysis except as allowed for by NI 43-101 in PEA studies. There is no guarantee that Inferred Resources can be converted to Indicated or Measured Resources, and as such, there is no guarantee the economics described herein will be achieved.

- The estimate of Mineral Resources may be materially affected by environmental, permitting, legal, marketing, or other relevant issues.

- The approximate 3-year trailing average (to November 30, 2025) metal price for molybdenum of US$49.59 per kg or US$22.50 (rounded down) per lb),US$300 per MTU or US$13.60 per pound W, and US$8.93 per kg or US$4.06 per pound Cu was used in estimating the Mineral Resources and a CAD:US Dollar exchange rate of $0.74 was used.

- A description of the key assumptions, parameters, and methods used to estimate the resources, and any known risks, as well as the data verification processes, will be contained in the Technical Report.

CAPITAL EXPENDITURES

The estimated project total pre-production capital expenditure, inclusive of contingencies and working capital, is approximately $672.3 million. A summary of project pre-production capital expenditures is presented in the following table.

| Table 6: Pre-Production Capital | |||||

| Year -3 | Year -2 | Year -1 | Year 1 | Total | |

| ($'000) | ($'000) | ($'000) | ($'000) | ($'000) | |

| Exploration | $ 1,000 | $ 1,000 | $ 1,000 | $3,000 | |

| Mine | $ 41,980 | $ 54,330 | $ 55,954 | $35,180 | $187,444 |

| Equipment Leasing | $ 0,659 | $ 10,450 | $ 10,240 | $31,350 | |

| Processing Plant | $ 70,000 | $ 65,917 | $35,000 | $170,917 | |

| Underground Infrastructure | $ 2,250 | $ 33,929 | $31,480 | $ 67,659 | |

| Surface Infrastructure & Mobile Equipment | $ 23,690 | $ 2,903 | $ 14,788 | $ 41,381 | |

| Tailings Management Facilities | $ 9,150 | $ 9,150 | |||

| Owner's Costs | $ 4,666 | $ 4,666 | $ 4,666 | $ 13,999 | |

| Contingency | $ 17,674 | $ 29,120 | $ 39,129 | $20,332 | $106,254 |

| Working Capital | $24,809 | $ 24,809 | |||

| Mine Closure | $ 10,000 | $ 10,000 | |||

| Total Capital Expenditures | $106,043 | $174,718 | $244,773 | $146,801 | $672,335 |

OPERATING COSTS

The estimated total average operating cost (excluding smelting and refining) for the mine is approximately $40.99 per tonne of potentially economic mineralization. This equates to $22.11 per kg of Mo ($10.03 per lb). The following table presents a summary of life of mine average operating costs per tonne.

| Table 7: Life of Mine Average Operating Costs | |

| Component | Cost |

| Diamond Drilling - Infill | $ 0.50 |

| Underground Mining | $ 22.47 |

| Equipment Leasing | $ 2.01 |

| Processing | $ 11.11 |

| Tailings Management Facility | $ 1.34 |

| Mine Indirects | $ 0.88 |

| Surface Department | $ 0.61 |

| General & Administration | $ 2.05 |

| Total Minesite Operating Cost | $ 40.99 |

ECONOMIC ANALYSIS

The expected cash flow estimates are calculated using the forecast mine plan, operating costs, and capital expenditures incorporating expected long-term metal prices based on the three-year trailing average of molybdenum on the London Metals Exchange of US $49.59 per kg or US $22.50 per pound of Mo, US$8.93 or US$4.06 per pound of Cu and US$300 per MTU or USS13.60 per pound of Wo and a CAD:US dollar exchange rate of $0.74.

A summary of the expected parameters used for the financial analysis is presented below.

Parameters Used in Financial Analysis

| Table 8: Cash Flow Model Input Parameters | |

| Parameter | |

| Longterm Metal Price ($US) | $ 49.59 ($22.50 /lb) |

| Exchange Rate | $1.35 $Can per $1 US |

| Diluted Mineral Resource | 72,074,709 tonnes |

| Dilution (at adjacent mineral grade) | 5% |

| Average Head Grade to Mill | 0.30% |

| Mill Recovery | 94% |

| Payability | 97% |

| Pre-Production Capital | $ 672.3 million |

| Total Sustaining Capital | $ 45.1 million |

| Working Capital | $ 24.8 million |

| Reclamation and Closure | $ 10 million |

| Estimated Operating Costs ($/tonne) | $40.99 |

| Life of Project | 20 Years |

The overall level of accuracy of this study is approximately ±40%.

The Project's expected investment and returns based on the base case cashflow parameters for the project are shown below.

| Table 9: Expected Project Returns | ||||

| Pre-Tax | After Tax | |||

| Undiscounted Net Revenue | $8.308 | billion | ||

| Undiscounted Total Cash Flow | $4.663 | billion | $2.920 | billion |

| NPV at 5% | $2.476 | billion | $1.502 | billion |

| NPV at 8% | $1.747 | billion | $1.034 | billion |

| IRR | 42% | 32% | ||

| Payback Period | 2.3 Years | |||

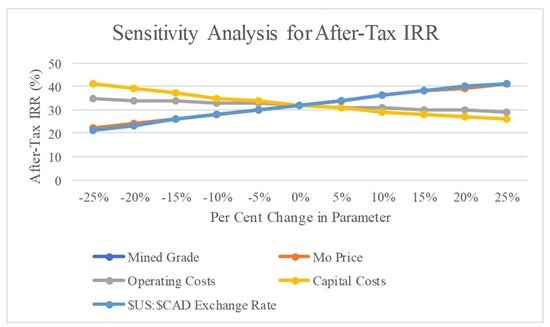

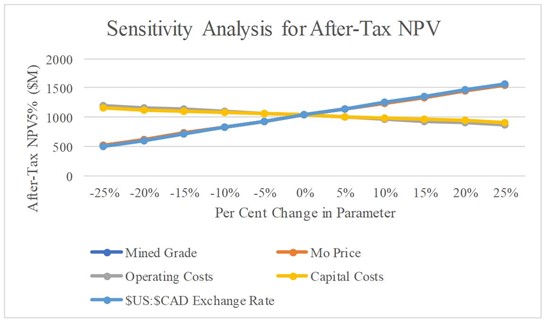

SENSITIVITY ANALYSIS

Sensitivity analyses were performed for capital expenditures, operating costs, mined grades, metal prices and currency exchange rates using 25% positive and negative variations. The Project is most sensitive to the mined grade, metal price and the exchange rate and less sensitive to capital and operating costs. The results of the sensitivity analysis for positive and negative changes of 25% in key project parameters are presented in the following tables and graphs.

Sensitivity Analysis Net Present Values ($CAD million)

| Table 10: Sensitivity Analysis for After-Tax NPV @ 8% | |||||||||||

| Parameter | After-Tax NPV ($M) | ||||||||||

| -25% | -20% | -15% | -10% | -5% | 0% | 5% | 10% | 15% | 20% | 25% | |

| Mined Grade | 514 | 619 | 724 | 829 | 932 | 1034 | 1135 | 1237 | 1339 | 1440 | 1542 |

| Mo Price | 514 | 619 | 724 | 829 | 932 | 1034 | 1135 | 1237 | 1339 | 1440 | 1542 |

| Operating Costs | 1200 | 1167 | 1133 | 1100 | 1067 | 1034 | 1000 | 967 | 934 | 900 | 866 |

| Capital Costs | 1151 | 1127 | 1104 | 1080 | 1057 | 1034 | 1010 | 987 | 963 | 939 | 914 |

| $US:$CAD Exchange Rate | 488 | 598 | 708 | 820 | 926 | 1034 | 1140 | 1247 | 1354 | 1461 | 1568 |

Note: The lines for Grade, Metal price and Exchange Rate are virtually the same and overlay each other.

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/7009/278892_moonriver_1.jpg

| Table 11: Sensitivity Analysis for After-Tax IRR @ 8% | |||||||||||

| Parameter | After-Tax IRR (%) | ||||||||||

| -25% | -20% | -15% | -10% | -5% | 0% | 5% | 10% | 15% | 20% | 25% | |

| Mined Grade | 22 | 24 | 26 | 28 | 30 | 32 | 34 | 36 | 38 | 39 | 41 |

| Mo Price | 22 | 24 | 26 | 28 | 30 | 32 | 34 | 36 | 38 | 39 | 41 |

| Operating Costs | 35 | 34 | 34 | 33 | 33 | 32 | 31 | 31 | 30 | 30 | 29 |

| Capital Costs | 41 | 39 | 37 | 35 | 34 | 32 | 31 | 29 | 28 | 27 | 26 |

| $US:$CAD Exchange Rate | 21 | 23 | 26 | 28 | 30 | 32 | 34 | 36 | 38 | 40 | 41 |

Sensitivity Analysis IRR

Note: The lines for Grade and Metal Price are virtually the same and overlay each other.

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/7009/278892_moonriver2.jpg

Non-IFRS Financial Measures

The Company has included certain terms or performance measures commonly used in the mining industry that are not defined under International Financial Reporting Standards ("IFRS") in this news release. These include Operating Costs, Cash Cost, AISC, Pre-Production Capital Expenditures, Sustaining Capital Expenditures and Life of Mine Average Operating Costs. Non-IFRS measures do not have any standardized meaning prescribed under IFRS, and therefore, they may not be comparable to similar measures employed by other companies. The data presented are intended to provide additional information and should not be considered in isolation or as a substitute for measures prepared in accordance with IFRS. Non-IFRS financial measures used in this news release and common to the mining industry are defined.

Operating Costs include mining, processing, general and administrative, concentrate transportation costs, treatment and refining charges, etc.

Cash costs include on-site mining costs plus on-site G&A, royalties/production taxes and permitting/community costs related to current operations, less byproduct credits, if any.

AISC includes total cash costs plus reclamation costs, exploration and study costs, sustaining capital exploration/development and sustaining capital expenditure.

Next Steps

The Company will commence baseline environmental studies and further engineering studies to advance and de-risk the Project once applicable First Nations consultations are undertaken.

Technical Report & Qualified Persons

A Technical Report on the PEA (the "Technical Report") prepared in accordance with National Instrument 43-101 Standards of Disclosure for Mineral Projects ("NI 43-101") will be filed on SEDAR+ under the Company's profile within 45 days of the date of this news release. Readers are encouraged to read the Technical Report in its entirety, including all qualifications, assumptions and exclusions that relate to the Mineral Resource. The Technical Report is intended to be read as a whole, and sections should not be read or relied upon out of context.

Qualified Persons

The scientific and technical content of this news release was reviewed, verified, and approved by Mr. Brian LeBlanc, P. Eng., President of AMPL, an independent "Qualified Person" ("QP") as defined by NI 43-101. Mr. LeBlanc is the QP responsible for the scientific and technical information contained in this news release.

About Moon River

Moon River is a Canadian-based resource company focused on the acquisition, exploration and development of mineral projects. Moon River is focused on the development of the Davidson Property which hosts a large molybdenum-tungsten-copper deposit and is located near Smithers, British Columbia. The Company also holds a 25% interest in one of the largest molybdenum mines in North America, the Endako Mine, also located in British Columbia.

For further information please contact:

Paul Parisotto, President, Chief Executive Officer and Director, at (416) 800-1753 or info@moonrivermoly.com.

Neither the TSXV nor its Regulation Services Provider (as that term is defined in the policies of the TSXV) accepts responsibility for the adequacy or accuracy of this release.

Forward-looking Statements:

This press release contains forward-looking statements and forward-looking information (collectively, "forward-looking statements") within the meaning of applicable securities laws. Any statements that are contained in this press release that are not statements of historical fact may be deemed to be forward-looking statements. Forward-looking statements are often identified by terms such as "may", "should", "anticipate", "will", "estimates", "believes", "intends", "expects", "plans" and similar expressions, which are intended to identify forward-looking statements. More particularly and without limitation, this press release contains forward-looking statements concerning metal price assumptions, cash flow forecasts, projected capital and operating costs, metal recoveries, mine life, production rates, infrastructure, permitting, potential enhancements to the Project, expected Project returns, and future plans set out in the Technical Report in respect of the PEA. These forward-looking statements reflect the current views of the Company, represent the expectations of the Company as of the date of this news release, and are based on certain assumptions that the Company and its consultants have made in preparing the PEA and Technical Report that will be filed in respect thereto within 45 days of this press release. There can be no assurance that the results particularly the expected Project returns will be achieved or the Mineral Resources that are not Mineral Reserves will be economically viability. The PEA mine plan and economic model include numerous assumptions and the use of Inferred Resources. Inferred Resources are considered to be too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves and to be used in an economic analysis except as allowed for by NI 43-101 in PEA studies. There is no guarantee that Inferred Resources can be converted to Indicated or Measured Resources, and as such, there is no guarantee the economics described herein will be achieved. Readers are encouraged to read the Technical Report in its entirety, including all qualifications, assumptions and exclusions that relate to the Mineral Resources. The Technical Report is intended to be read as a whole, and sections should not be read or relied upon out of context.

Although the Company believes the expectations and material factors and assumptions reflected in these forward-looking statements are reasonable as of the date hereof, there can be no assurance that these expectations, factors and assumptions will prove to be correct. These forward-looking statements are not guarantees of future performance and are subject to a number of known and unknown risks and uncertainties including risks detailed in the PEA and continuous disclosure including the Technical Report, which are or will be available on SEDAR+ at www.sedarplus.ca. Accordingly, readers should not place undue reliance on the forward-looking statements contained in this press release.

These risk factors should not be construed as exhaustive. Readers are cautioned that events or circumstances could cause results to differ materially from those predicted, forecasted or projected in the PEA and the Technical Report in respect thereof. The forward-looking statements contained in this press release speak only as of the date of this press release.

These forward-looking statements reflect the current views of the Company, represent the expectations of the Company as of the date of this press release, and are based on certain assumptions that the Company has made in respect thereof as at the date of this press release.

The Company does not undertake any obligation to publicly update or revise any forward-looking statements or information contained herein, except as required by applicable laws. The forward-looking statements contained in this document are expressly qualified by this cautionary statement.

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/278892

Source: Moon River Moly Ltd.