Toronto, Ontario--(Newsfile Corp. - September 9, 2025) - Black Swan Graphene Inc. (TSXV: SWAN) (OTCQX: BSWGF) (FSE: R960) ("Black Swan" or the "Company") is pleased to report compelling performance results from production-scale trials conducted by one of its partners, a global masterbatch manufacturer, including testing at end-customer facilities. For one marquee consumer-products program, Black Swan was advised that its graphene-enhanced formulation delivered superior results versus alternative materials evaluated by that specific customer, reinforcing the Company's view that its approach to Graphene-Enhanced Masterbatch™ ("GEM™") is highly competitive in targeted high-volume applications. Customers and application details shall remain confidential for commercial reasons.

Consumer Packaging

In the consumer packaging sector, trials with a major customer for polyethylene terephthalate ("PET") bottles and films demonstrated significant improvements in oxygen and water vapour barrier properties. Based on the results, the customer is moving forward with additional diligence and commercial dialogues toward a possible long-term supply arrangement, citing Black Swan's formulation as delivering superior results to alternative graphene manufacturers.

In support this opportunity, Black Swan has recently initiated a full Food and Drug Administration ("FDA") approval process with a globally recognized third-party testing and certification body. While there can be no guarantee, securing FDA food-contact clearance via an effective Food Contact Notification (FCN) would represent a critical milestone, paving the way for the widespread commercialization of graphene-enhanced packaging solutions across global supply chains.

Mobility

Validation also extends to the high-performance plastics sector, where trials in automotive applications using polypropylene ("PP") and polyamide ("PA") polymers have delivered highly encouraging results. The graphene-enhanced materials demonstrated significantly improved impact resistance along with notable lightweighting benefits - two critical factors for advancing both fuel efficiency and safety in modern vehicles. These attributes align directly with the automotive industry's drive toward electrification and sustainability, where stronger, lighter materials play a pivotal role.

In parallel, the construction sector is showing similar promise. Trials with PP pipes revealed excellent lightweighting - or "downgauging" - potential, enabling manufacturers to reduce material usage and costs without sacrificing structural integrity. Such advances underscore graphene's ability to enhance performance while supporting more sustainable and resource-efficient manufacturing practices.

"First, although we are unable to identify the customers, the engagements are with a globally recognized brand. The commercial potential is notable, and we are moving forward with discipline and discretion. Second, we are achieving exactly what we set out to prove: with the right dispersion and the right loading, our graphene products can unlock properties that matter at industrial scale. These partner-led trials validate the strength of our GEM model confirming that we can provide a reliable pathway for global manufacturers to integrate graphene seamlessly into existing production processes. Importantly, the results demonstrate not only technical performance, but also commercial viability, positioning Black Swan to capture significant near-term opportunities as we advance toward high-volume production. This is a powerful testament to the commercial readiness of our graphene solutions," said Simon Marcotte, President & Chief Executive Officer of Black Swan.

What Customers Are Seeking

Across multiple development programs with the same masterbatch partner and others, Black Swan is addressing performance targets that include:

- Barrier performance (oxygen and moisture) for shelf-life and product-quality retention;

- Impact resistance and toughness for durability and safety;

- Light weighting (downgauging) to reduce material usage while maintaining performance; and

- Consistent dispersion in standard compounding lines-without special dispersants-enabling fast qualification.

Built to Scale: Capacity & Cost

To support volume adoption, Black Swan has initiated a major capacity expansion at its UK site to approximately 140 tonnes per year, positioning the Company among the larger graphene producers and enabling competitive pricing dynamics as volumes ramp. The expansion leverages existing infrastructure to minimize capex and accelerate time to output.

"Volume and price are decisive in the markets we are targeting. With our installed and expanding capacity, our GEM strategy, and our global partner network, we believe we are equipped to deliver both at scale," said Michael Edwards, Chief Operating Officer of Black Swan.

Market Context

While specific end-uses remain undisclosed, Black Swan is targeting high-volume segments where barrier, durability, and light-weighting are critical and where GEM can be a drop-in-friendly solution:

- PET bottles represent a very large addressable packaging category, with 2024 global market size estimates around US$45-50B and steady growth expected through the next decade.[1]

- High-barrier films (including PET/PEN structures) are a multi-tens-of-billions market focused on oxygen and moisture control for quality and shelf-life.[2]

- Automotive polymers rely heavily on PP and PA for light-weighting and impact performance; PP is the leading automotive plastic by share, and the broader automotive-plastics market is poised for continued growth.[3]

- Plastic piping is a large, growing global market in which weight and wall-thickness (downgauging) are key cost levers.[4]

Next Steps

Black Swan and its partners will continue application-specific optimization and scaling activities, including additional customer pilots and regulatory steps where required. The Company will provide further updates as milestones are achieved.

Polymer Product Performances

It is paramount to underscore that Black Swan's products are the results of extensive internal development efforts, including independent verification using the expertise at the Graphene Engineering Innovation Centre ("GEIC") and a strategic partnership with high-profile masterbatch partners. The primary objective of the product development endeavors extends beyond performance; it strives for consistency, a pivotal factor in the commercialisation of additive products. In this context, the outcomes detailed herein stand as a testament to their reliability, and the independent validations reinforces their validity. Black Swan GEM products also offer a price-performance improvement without disruption to the supply chain.

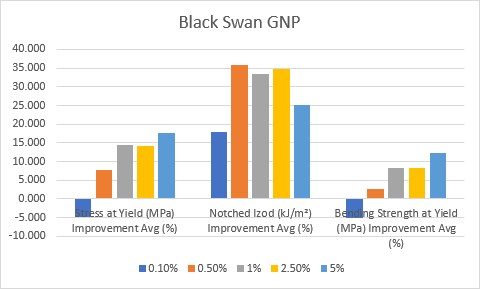

As visualised in the chart below, initial production volumes are focused on polypropylene; a widely used polymer known for its versatility and cost-effectiveness. However, its relatively low impact resistance has often posed a challenge in various applications. By incorporating only 1% of graphene into the polypropylene (loading ratio), an impressive 30% improvement in impact resistance was achieved in a Notched Izod test, which assesses the amount of energy absorbed by a material when struck by a notched sample.

Graphene-enhanced products, with the addition of Black Swan's product, demonstrate multiple performance benefits, including enhanced processability and therefore cost-effectiveness. Masterbatches with a loading ratio of up to 20% are available in various polymers. This repeatable performance in enhancing the impact resistance of polypropylene enables new possibilities across multiple industries, notably for different packaging and lightweighting in the transportation industry, a key driver for range increase and fuel efficiency.

Black Swan and different masterbatch partners are also working with the polymer matrix of a world-leading industrial polymer manufacturer, which launched an aggressive initiative to develop plastic materials for electric vehicles aimed at reduced weight, expand design freedom, reduce complexity, enhance thermal management, and reduce environmental impact. The development program resulted thus far in a 20% improvement in tensile strength, based on a loading ratio of only 0.2%.

"These results further add weight to the potential benefits of incorporating graphene materials into thermoplastics. A 30% impact resistance improvement is exciting, and we are looking to expand these trials into commercial applications. We are also able to fine-tune compound properties to deliver customer specific solutions. The enhanced capabilities of graphene-enhanced polypropylene have the potential to reshape entire industries," said Simon Marcotte, President and Chief Executive Officer.

The chart below provides results using Black Swan's product, based on different loading ratios, for "Stress at Yield", which determines the amount of stress a material can withstand before undergoing permanent deformation, "Notched Izod", which determines the impact resistance qualities as discussed above, and "Bending Strength at Yield", which measures the ability to withstand bending or flexural loads.

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/2855/265510_6697cb36143908ee_001full.jpg

About Black Swan Graphene Inc.

Black Swan is focused on the large-scale production and commercialization of patented high-performance and low-cost graphene products aimed at several industrial sectors, including concrete and polymers, which are expected to require large volumes of graphene. Black Swan's graphene processing technology was developed by Thomas Swan over the last decade. Thomas Swan is a United Kingdom-based global chemicals manufacturer, with a century-long track record and has been at the forefront of graphene innovation.

More information is available at: www.blackswangraphene.com.

For more information please contact:

Paul Hardy, Vice President - Corporate Development

phardy@blackswangraphene.com

+1 (416) 844-7365

Black Swan Graphene Inc. on behalf of the Board of Directors

Simon Marcotte, CFA, President & Chief Executive Officer

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Forward-Looking Statements

The information contained herein contains "forward-looking statements" within the meaning of applicable securities legislation. Forward-looking statements relate to information that is based on assumptions of management, forecasts of future results, and estimates of amounts not yet determinable. Any statements that express predictions, expectations, beliefs, plans, projections, objectives, assumptions or future events or performance are not statements of historical fact and may be "forward-looking statements." Forward-looking statements are subject to a variety of risks and uncertainties which could cause actual events or results to differ from those reflected in the forward-looking statements, including, without limitation: risks related to the likelihood that the trials will lead to positive commercial applications and long-term supply arrangements, the likelihood that Black Swan will be successful in obtaining FDA approval on a timely basis, or at all, that reported promise in the plastics and construction sectors will translate to commercial viability, that the planned capacity expansion will result in obtaining the desired price and volume competitive advantage, risk related to the failure to obtain adequate financing on a timely basis and on acceptable terms; risks related to the outcome of legal proceedings; political and regulatory risks associated with the industry; risks related to the maintenance of stock exchange listings; risks related to environmental regulation and liability; the potential for delays in development activities or the completion of feasibility studies; the uncertainty of profitability; risks related to the inherent uncertainty of production and cost estimates and the potential for unexpected costs and expenses; results of feasibility studies, and the possibility that future results will not be consistent with the Company's expectations; risks related to commodity prices fluctuations; and other risks and uncertainties related to the Company's prospects, properties and business detailed elsewhere in the Company's disclosure record. Should one or more of these risks and uncertainties materialize, or should underlying assumptions prove incorrect, actual results may vary materially from those described in forward-looking statements. Furthermore, performance results of graphene products as additives can vary widely depending on type and the specificity of the target material, the specifics of the graphene product itself, including but not limited to, carbon purity, particle size, surface agent, dispersion behavior, and application and usage methods. Investors are cautioned against attributing undue certainty to forward-looking statements and initial test results. These forward-looking statements and test results are made as of the date hereof and the Company does not assume any obligation to update or revise them to reflect new events or circumstances, except in accordance with applicable securities laws. Actual events or results could differ materially from the Company's expectations or projections.

[1] https://www.imarcgroup.com/pet-bottle-manufacturing-plant?utm_source=chatgpt.com

[2] https://www.grandviewresearch.com/industry-analysis/barrier-films-market-report

[3] https://www.alliedmarketresearch.com/automotive-plastics-market?utm_source=chatgpt.com

[4] https://www.precedenceresearch.com/plastic-pipe-market?utm_source=chatgpt.com

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/265510

Source: Black Swan Graphene Inc.