Tamarack, Minnesota--(Newsfile Corp. - November 4, 2025) - Talon Metals Corp. (TSX: TLO) ("Talon" or the "Company"), voted by the MINING.COM community as the number-one ranked small-cap mining stock ($200 million to $2 billion) for October 20251, is pleased to provide an update on exploration work in the Vault Zone at the Tamarack Nickel-Copper-Cobalt Project in Minnesota (the "Tamarack Nickel-Copper Project").

Drilling to date has defined a pattern of multiple accumulations of massive sulphides within the Vault Zone, and new borehole electromagnetic ("BHEM") data indicates that this pattern may repeat for more than 300 meters below the deepest intercept drilled to date. Talon is also pleased to announce the successful transition of its full exploration team from Michigan back to Tamarack, enabling an expanded three-rig drilling campaign focused on rapidly advancing the high-priority Vault Zone. The Company further reports complete assay results from drill hole 25TK0563, representing the highest nickel-equivalent grade multiplied by length interval in the Tamarack Nickel-Copper Project's history.

Record Intercept in Drill Hole 25TK0563

Building on partial results disclosed on June 5, 2025, the remaining assays from drill hole 25TK0563 include 89.50 meters grading 1.06% NiEq (1.89% CuEq) starting at 419.5 meters depth (see Table 2). When combined with the previously reported 34.9 meters of massive sulphide mineralization grading 28.88% NiEq (57.76% CuEq), the drill hole returned a total of 390.17 meters grading 3.23% NiEq (6.14% CuEq) -the highest nickel-equivalent grade multiplied by length interval ever recorded at the Tamarack Nickel-Copper Project.

Full Exploration Team Returns to Tamarack

Since August, directional drilling at the Tamarack Nickel-Copper Project, carried out by one crew operating between two drill pads, targeted holes 25TK0563A, 25TK0565A and the extension of historic hole 16TK0248 (originally drilled in 2016) to collect BHEM data. Unfortunately, drill hole 25TK0565A was lost before target depth due to mechanical failure.

With drilling at Talon's Michigan Boulderdash discovery halted for the Winter 2025/2026 snow season, all three drill rigs that were in Michigan and Talon's full in-house exploration team have been relocated to Tamarack. The expanded program is operating from three dedicated drill pads and is focused on the rapid delineation of resources within the Vault Zone.

Significant Geophysical and Geological Indicators

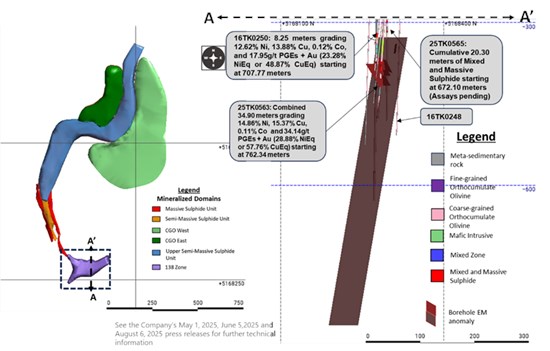

BHEM surveys from the extension of historic drill hole 16TK0248 identified a high-conductivity plate interpreted to represent the lateral continuation of the high-grade nickel-copper-PGE mineralization intersected in drill hole 25TK0563. This response aligns with high-conductivity plates modeled from drill holes 25TK0563 and 25TK0562 (see Figure 1), together supporting the interpretation of continuous massive sulphide mineralization along this stratigraphic level (see conceptual illustration of accumulations of massive sulphides based on drilling to date in Figure 2).

BHEM surveys from drill hole 25TK0565 and from the deepening of historic drill hole 16TK0250 (see Figure 1) also indicate potential lateral continuity of massive sulphides, this time within the upper parts of the stratigraphy (see conceptual illustration of accumulations of massive sulphides based on drilling to date in Figure 2).

Unlike the Tamarack Resource Area, the extension of drill hole 16TK0248 also modeled a weaker near-vertical conductor extending more than 300 meters below the deepest massive sulphide intercept in the Vault Zone.

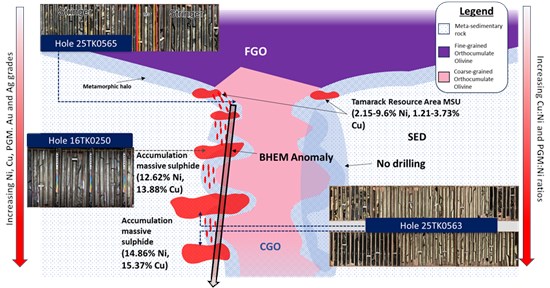

Together, these results reinforce the emerging model for the Vault Zone, in which massive sulphides accumulated in multiple repeating stacks developed along the contact between the intrusion and the surrounding sediments. At this boundary, heat from the intrusion partially melted the country rock, creating permeable zones (traps) that allowed sulphides to migrate and concentrate. For comparison, a single stack of the massive sulphide unit (MSU) in the Tamarack Resource Area formed in similar geological setting and has a lateral continuation for up to approximately 600 meters.

The newly identified near-vertical, low-conductivity detected in 16TK0248 is interpreted to represent a connective pathway-indicating that the repetitive process of sulphide accumulation and lateral extension along stacks may repeat for more than 300 meters below the deepest known intercepts in the Vault Zone.

To date, there has been no drilling on the northern part of the intrusion in the Vault Zone (see Figure 2), where the system remains completely open for discovery. At the Tamarack Resource Area, massive sulphides accumulate on both sides of the intrusion-forming two distinct limbs of mineralization developed along the western and eastern contacts (see plan view in Figure 1). This geometry will guide the Talon exploration team to evaluate the opposite, undrilled side of the intrusion at the Vault Zone for potential stacks of massive sulphides.

Figure 1: Cross section of the Vault Zone looking west, showing a large conductive structure representing an extensive pathway that hosts the observed stacked sequence of high-grade nickel-copper mineralization

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/2443/273054_7092a860e44e191c_001full.jpg

Figure 2: Conceptual cross-section through the Vault Zone showing the stack of previously intercepted high-grade nickel-copper-PGE mineralization. The near-vertical BHEM plate shown in Figure 1 (see conceptual placement) is interpreted to reflect a controlling structure for these known massive sulphides. The modelled conductor persists for hundreds of metres below the deepest intercept in drill hole 25TK0563

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/2443/273054_7092a860e44e191c_002full.jpg

Additionally, results from drill hole 25TK0563A have identified the highest occurrences of chalcocite veining and bornite-chalcopyrite assemblages, minerals not typically observed at the Tamarack Nickel Copper Project, indicating significant copper enrichment over a span of approximately 150-meters between drill holes in the Vault Zone. This hypogene-style enrichment points to a unique geological process, not seen in the Tamarack Resource Area, enhancing the copper potential of the system (see Figure 3).

Figure 3: An example of massive chalcocite and bornite identified in hole 25TK0563A in the Vault Zone

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/2443/273054_7092a860e44e191c_003full.jpg

Next Steps: Accelerated Vault Zone Delineation

During the Fall 2025 and Winter 2026 season, Talon's fully crewed, three-rig drilling campaign will continue the targeting of BHEM plates to determine:

The lateral extent of massive sulphide and mixed massive sulphide stacks of accumulations of sulphides intercepted in drill holes 16TK0250, 25TK0565 and 25TK0563 (see left side of the conceptual cross section in Figure 2);

The potential for similar massive sulphide and mixed massive sulphide stacks on the opposite side of the intrusion, an area with no prior drilling (see right side of the conceptual cross section in Figure 2); and

Additional accumulation of massive sulphides and mixed massive sulphide stacks at greater depths by following the near-vertical BHEM plate from 16TK0248 deeper into the Vault Zone, potentially beyond 300 meters below the deepest massive sulphide intercept to date.

Successive drill targets will be refined based on ongoing geological and geophysical insights.

"Geophysically speaking, the initial borehole electromagnetic (BHEM) results from the Vault Zone appear analogous to the geometry of the Reid Brook Zone at Voisey's Bay, where I worked for over five years," said Brian Bengert, Talon's VP Geophysics. "What's particularly exciting is the clear contrast between the near-vertical, lower-conductivity feature, interpreted as a pathway connecting the accumulations, and the high-conductivity plates that define the accumulations themselves. This conductivity contrast should significantly improve the speed and accuracy of exploration. A single vertical drill hole with multiple directional daughter holes should be able to efficiently delineate several lateral extensions of these sulphide traps."

"Unlike the Tamarack Resource Area, where massive sulphide mineralization typically forms as a single laterally continuous accumulation on either side of the intrusion (see plan view in Figure 1), the Vault Zone shows multiple accumulations of massive sulphides-each with potential for lateral extension," said Brian Goldner, Talon's Chief Exploration and Operations Officer. "Importantly, tenor and grades increase with depth, with the highest nickel, copper and Cu:Ni ratios-and the most intense bornite and chalcocite veining-ever observed at the Tamarack Nickel-Copper Project."

"With only a subset of our team at Tamarack, we've completed seven holes to target depth in the Vault Zone that delivered some of the highest-grade nickel-copper intercepts drilled in the last century-but that's still just seven holes in a vast area," said Henri van Rooyen, CEO of Talon. "Now that our Michigan team has returned to Tamarack for the Fall 2025 and Winter 2026 season, we've established three drill pads directly above the Vault Zone, enabling 360-degree directional drilling that saves roughly 2,000 meters per pad compared to drilling each hole from surface. We're now positioned to follow each massive sulphide stack laterally and continue tracing the same pattern to greater depths-while also testing the opposite side of the intrusion for additional stacks of high-grade nickel-copper-PGE mineralization."

For further discussion on the Vault Zone, please see www.talonmetals.com/media.

QUALITY ASSURANCE, QUALITY CONTROL AND QUALIFIED PERSONS

Please see the technical report entitled "November 2022 National Instrument 43-101 Technical Report of the Tamarack North Project - Tamarack, Minnesota" with an effective date of November 2, 2022 ("November 2022 Technical Report") prepared by independent "Qualified Persons" (as that term is defined in National Instrument 43-101 ("NI 43-101")) Brian Thomas (P. Geo), Roger Jackson (P. Geo), Oliver Peters (P. Eng) and Christine Pint (P.G) for information on the QA/QC, data verification, analytical and testing procedures at the Tamarack Nickel Copper Project. Copies are available on the Company's website (www.talonmetals.com) or on SEDAR at (www.sedar.com). The laboratory used is ALS Minerals who is independent of the Company.

Lengths are drill intersections and not necessarily true widths. True widths cannot be consistently calculated for comparison purposes between holes because of the irregular shapes of the mineralized zones. Drill intersections have been independently selected by Talon. Drill composites have been independently calculated by Talon. The geological interpretations in this news release are solely those of the Company. The locations and distances highlighted on all maps in this news release are approximate.

Dr. Etienne Dinel, Vice President, Geology of Talon, is a Qualified Person within the meaning of NI 43-101. Dr. Dinel is satisfied that the analytical and testing procedures used are standard industry operating procedures and methodologies, and he has reviewed, approved and verified the technical information disclosed in this news release, including sampling, analytical and test data underlying the technical information.

Where used in this news release:

NiEq% = Ni% + Cu% x $4.00/$8.00 x Cu Recovery/Ni Recovery + Co% x $20.00/$8.00 x Co Recovery/Ni Recovery + Pt [g/t]/31.103 x $1,000/$8.00/22.04 x Pt Recovery/Ni Recovery + Pd [g/t]/31.103 x $1,000/$8.00/22.04 x Pd Recovery/Ni Recovery + Au [g/t]/31.103 x $2,000/$8.00/22.04 x Au Recovery/Ni Recovery + Ag [g/t]/31.103 x $20.00/$8.00/22.04 x Ag Recovery/Ni Recovery

CuEq% = Cu%+ Ni% x $8.00/$4.00 x Ni Recovery/Cu Recovery + Co% x $20.00/$4.00 x Co Recovery/Cu Recovery + Pt [g/t]/31.103 x $1,000/$4.00/22.04 x Pt Recovery/Cu Recovery + Pd [g/t]/31.103 x $1,000/$4.00/22.04 Pd Recovery/Cu Recovery + Au [g/t]/31.103 x $2,000/$4.00/22.04 Au Recovery/Cu Recovery + Ag [g/t]/31.103 x $20.00/$4.00/22.04 x Ag Recovery/Cu Recovery

For Ni and Cu recoveries, please refer to the formulae in the November 2022 Technical Report. Recovery of Ni to the Cu concentrate was excluded from the NiEq calculation. The following recoveries were used for the other metals: 64.1% for Co, 82.5% for Pt, 69.3% for Pd and 72.6% for Au and Ag.

ABOUT TALON

Talon is a TSX-listed base metals company in a joint venture with Rio Tinto on the high-grade Tamarack Nickel Copper Project Tamarack Nickel-Copper-Cobalt Project located in central Minnesota. Talon's shares are also traded in the US over the OTC market under the symbol TLOFF. The Tamarack Nickel Copper Project comprises a large land position (18km of strike length) with additional high-grade intercepts outside the current resource area. Talon has an earn-in right to acquire up to 60% of the Tamarack Nickel Copper Project and currently owns 51%. Talon has a neutrality and workforce development agreement in place with the United Steelworkers union. Talon's Battery Mineral Processing Facility in Mercer County was selected by the US Department of Energy for US$114.8 million funding grant from the Bipartisan Infrastructure Law and the US Department of War awarded Talon a grant of US$20.6 million to support and accelerate Talon's exploration efforts in both Minnesota and Michigan. Talon has well-qualified experienced exploration, mine development, external affairs and mine permitting teams.

For additional information on Talon, please visit the Company's website at www.talonmetals.com or contact:

| Media Contact: Jessica Johnson (218) 460-9345 johnson@talonmetals.com | Investor Contact: Mike Kicis 1 (647) 968-0060 kicis@talonmetals.com |

FORWARD-LOOKING STATEMENTS

This news release contains certain "forward-looking statements". All statements, other than statements of historical fact that address activities, events or developments that the Company believes, expects or anticipates will or may occur in the future are forward-looking statements. These forward-looking statements reflect the current expectations or beliefs of the Company based on information currently available to the Company. Such forward-looking statements include statements relating to future exploration work, including future drill holes, drill results, assays, geophysics and geological interpretations. Forward-looking statements are subject to significant risks and uncertainties and other factors that could cause the actual results to differ materially from those discussed in the forward-looking statements, and even if such actual results are realized or substantially realized, there can be no assurance that they will have the expected consequences to, or effects on the Company.

Any forward-looking statement speaks only as of the date on which it is made and, except as may be required by applicable securities laws, the Company disclaims any intent or obligation to update any forward-looking statement, whether as a result of new information, future events or results or otherwise. Although the Company believes that the assumptions inherent in the forward-looking statements are reasonable, forward-looking statements are not guarantees of future performance and accordingly undue reliance should not be put on such statements due to the inherent uncertainty therein.

Table 1: Collar Locations of Drill Holes

| Drill Hole # | Easting (m) | Northing (m) | Elevation (masl) | Azm | Dip | End Depth (m) |

| 16TK0248 | 491049.3 | 5168348.1 | 388.7 | 139.7 | -86.8 | 898.6 |

| 25TK0563A | 491049.3 | 5168348.9 | 388.0 | 170.4 | -85.4 | 842.2 |

| 25TK0565A | 490998.2 | 5168295.3 | 388.0 | 85.7 | -88.3 | 787.3 |

| Collar coordinates are UTM Zone 15N, NAD83. Azimuths and dips are taken from the survey record at collar unless otherwise noted. | ||||||

Table 2: Assay Table for Drill Hole 25TK0563

| Drill Hole # | From (m) | To (m) | Length (m) | Assay | NiEq (%) | CuEq (%) | ||||||

| Ni (%) | Cu (%) | Co (%) | Pd (g/t) | Pt (g/t) | Au (g/t) | Ag (g/t) | ||||||

| 25TK0563 | 419.50 | 509.00 | 89.50 | 0.65 | 0.49 | 0.02 | 0.09 | 0.16 | 0.12 | ** | 1.06 | 1.89 |

| and | 522.23 | 524.64 | 2.41 | 2.14 | 0.92 | 0.05 | 0.22 | 0.38 | 0.20 | ** | 2.85 | 5.59 |

| and | 533.50 | 540.50 | 7.00 | 1.17 | 0.51 | 0.03 | 0.20 | 0.30 | 0.15 | ** | 1.62 | 3.16 |

| and | 713.25 | 723.50 | 10.25 | 0.64 | 1.10 | 0.02 | 0.37 | 0.68 | 0.34 | ** | 1.63 | 2.80 |

| *Combined | 762.34 | 782.73 | 34.90 | 14.86 | 15.37 | 0.11 | 8.65 | 16.31 | 9.18 | 42.92 | 28.88 | 57.76 |

| 795.16 | 809.67 | |||||||||||

| 25TK0563 | 419.50 | 809.67 | 390.17 | 1.65 | 1.60 | 0.02 | 0.84 | 1.57 | 0.89 | 4.08 | 3.23 | 6.14 |

| Length refers to drill hole length and not True Width. True Width is unknown at the time of publication. All samples were analysed by ALS Minerals. Nickel, copper, and cobalt grades were first analysed by a 4-acid digestion and ICP AES (ME-MS61). Grades reporting greater than 0.25% Ni and/or 0.1% Cu, using ME-MS61, trigger a sodium peroxide fusion with ICP-AES finish (ICP81). Platinum, palladium, and gold are initially analyzed by a 30g fire assay with an ICP-MS finish (PGM-MS24). Any samples reporting >1g/t Pt or Pd trigger an over-limit analysis by ICP-AES finish (PGM-ICP27) and any samples reporting >1g/t Au trigger an over-limit analysis by AAS (Au-AA26). For Ag, ICP-AES through Aqua regia digestion (ME-ICP 41). * See Company's press release dated June 5, 2025 for additional technical information ** Silver (Ag) was not analysed in the shallower section of the drill hole | ||||||||||||

Table 3: Quick Lithology Log for Drill Holes

| Drill Hole # | From (m) | To (m) | length | Quick Log | % Sulphides |

| 16TK0248 | 0 | 697.49 | Drilled by Kennecott Exploration Company in 2016 | ||

| 697.49 | 721.46 | CGO | Traces | ||

| 721.46 | 734.73 | CGO | 2% | ||

| 734.73 | 736.87 | SED | 5% | ||

| 736.87 | 738.22 | CGO | 1% | ||

| 738.22 | 744.17 | SED | Traces | ||

| 744.17 | 893.80 | CGO | Traces | ||

| 893.80 | 898.55 | SED | |||

| 25TK0563A | 600.30 | 607.77 | CGO | Traces | |

| 607.77 | 720.35 | CGO | Traces | ||

| 720.35 | 754.99 | 34.64 | MI | 3-10% | |

| 754.99 | 768.40 | CGO | 3% | ||

| 768.40 | 780.92 | SED | 5% | ||

| 780.92 | 842.16 | SED | Traces | ||

| 25TK0565A* | 550.77 | 559.61 | CGO | 1% | |

| 559.61 | 576.38 | MZNO | 1 | ||

| 576.38 | 701.04 | CGO | Tr-3% | ||

| 701.04 | 702.26 | MZNO | |||

| 702.26 | 730.91 | CGO | 0.5-2% | ||

| 730.91 | 751.64 | MZNO | |||

| 751.64 | 778.76 | 27.12 | CGO | 1-5% | |

| 778.76 | 780.90 | 2.14 | MI | 10% | |

| 780.90 | 784.56 | CGO | Traces | ||

| Quick lithology log of drill holes: Overburden (OB); Meta-sedimentary rocks (SED); Fine-grained Orthocumulate/Mixed Zone (MZNO); Coarse-grained Orthocumulate (CGO); Mafic Intrusive (MI). *Drill hole 25TK0565A was lost before target depth. | |||||

________________________

1 https://www.mining.com/ranking monthly contest aggregates real-time votes from its global community of mining professionals, executives, and investors. Participants vote for up to 5 stocks per league (Large-Cap: >$2B; Small-Cap: $200M-$2B; Micro-Cap: <$200M). Rankings are determined by vote percentage share. Votes are submitted directly via the Ranking page. Incomplete or non-compliant entries are excluded. Results update live and reset monthly. Achieving the #1 position signifies Talon Metals received the highest percentage of community votes (8.6%) in the Small-Cap League for October 2025, spotlighting it as the top-voted small-cap mining stock globally for the month.

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/273054

Source: Talon Metals Corp.