Vancouver, British Columbia and Melbourne, Australia--(Newsfile Corp. - October 1, 2025) - Southern Cross Gold Consolidated Ltd (TSX:SXGC) (ASX: SX2) (OTCQX: SXGCF) (FSE: MV3) ("SXGC", "SX2" or the "Company") announces results from five diamond drill holes from the Rising Sun prospect, of the 100%-owned Sunday Creek gold-antimony project in Victoria (Figures 1 to 6).

Five Key Points

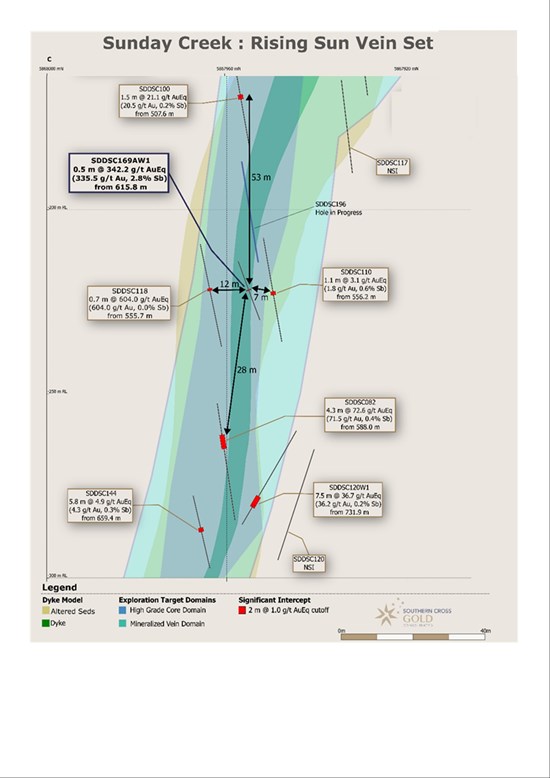

Strike Continuity Confirmed: SDDSC169AW1 intercepted 0.5 m @ 342.2 g/t AuEq just 12 m along strike from SDDSC118's previously reported 0.7 m @ 604.0 g/t AuEq intersection, demonstrating high-grade continuity within the RS15 vein

Broad Mineralized Zones Host Multiple High-Grade Shoots: SDDSC178W1 returned 18.0 m @ 3.7 g/t AuEq containing four distinct higher-grade intervals, while SDDSC169AW1 delivered 5.9 m @ 4.6 g/t AuEq and 6.1 m @ 3.4 g/t AuEq, demonstrating both scale and grade

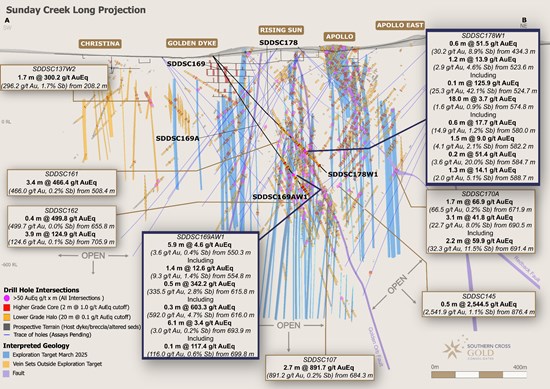

Stacked Vein Architecture Confirmed: Successfully intercepted seven distinct mineralized vein sets in SDDSC169AW1 and nine vein sets in SDDSC178W1 across vertical intervals exceeding 160 m, confirming the multi-level nature of the Rising Sun system

High Antimony Grades: Three individual assays exceeded 40% Sb (approaching pure stibnite at approximately 71% Sb), including 43.8 % Sb and 42.1 % Sb, reinforcing Sunday Creek's strategic importance as a Western World antimony source

Project Milestone: Results bring the total to 70 intersections >100 g/t AuEq x m and 74 intersections >50 to 100 g/t AuEq x m across Sunday Creek, establishing it as one of the highest-grade gold projects globally

Michael Hudson, President & CEO, states: "Sunday Creek again delivers grade and scale. While we've established the continuity in the up-and-down orientation of the vein sets through extensive drilling, it's now, with this more recent focus on along-strike drilling, that we're seeing further lateral grade continuity confirmed. SDDSC169AW1's intersection of 0.5 m @ 342 g/t AuEq being just 12 m along strike from our previous 0.7 m @ 604 g/t AuEq intersection in the RS15 vein reconfirms that the high grades extend consistently in multiple directions.

"What makes Sunday Creek unique isn't just the high grades - it's the combination of high grades with broader mineralized widths. SDDSC178W1's 18 m @ 3.7 g/t AuEq interval exemplifies this perfectly, containing four distinct higher-grade vein sets within a single broad envelope. This demonstrates how stacked vein sets can create substantially wider zones that are potentially mineable. Additionally, with three zones exceeding 40% Sb alongside these high-grade, broad gold-rich intervals, Sunday Creek showcases a rare combination of grade in two attractive commodities and significant width.

"This announcement at Rising Sun, along with previous announcements over the last 2 months at Apollo East, Golden Dyke and Christina, demonstrates significant progress with resource drilling and confidence in the continuity of mineralization, as well as extending the Exploration Target. With 70 drill intersections now exceeding 100 gram-metre AuEq across the project, and our successful use of wedge technology enabling precise targeting of these vein sets, Rising Sun, as one of five bodies across Sunday Creek, continues to deliver on scale, grade, and continuity. This is exceptional by any global standard."

FOR THOSE WHO LIKE THE DETAILS

Key Take Aways

SDDSC169AW1 - Confirming RS15 Lateral Continuity:

Intercepted seven distinct vein sets using wedge technology after initial hole deviation

0.5 m @ 342.2 g/t AuEq (335.5 g/t Au, 2.8% Sb) from 615.7 m, located just 12 m along strike from previous 0.7 m @ 604 g/t AuEq intersection from 555.7 m, proving exceptional lateral grade continuity in RS15 vein. Individual assay of 0.3 m @ 592.0 g/t Au from 616.0 m represents some of the highest gold grades at Rising Sun

5.9 m @ 4.6 g/t AuEq from 550.3 m includes 1.4 m @ 12.6 g/t AuEq, demonstrating broader mineralization enveloping high-grade cores

Four separate mineralized intervals from 550 m to 700 m depth demonstrate stacked vein set architecture across 150 m vertical extent

SDDSC178W1 - Multiple High-Grade Vein Sets with Exceptional Antimony:

Successfully intercepted nine vein sets after wedging from deviated parent hole, with mineralization intersected from 434 m to 593 m which shows excellent vertical continuity across 160 m

18.0 m @ 3.7 g/t AuEq from 574.8 m represents the broadest mineralized interval in these results, containing four distinct higher-grade zones including 0.6 m @ 17.7 g/t AuEq and 1.5 m @ 9.0 g/t AuEq

Record antimony grades with three assays >40 % Sb, including 0.13 m @ 43.8% Sb from 589.8 m and 0.13 m @ 42.1% Sb 524.7 m (approaching pure stibnite at approx. 71 % Sb)

1.2 m @ 13.9 g/t AuEq 524.0 m includes 0.1 m @ 125.9 g/t AuEq combining both high gold (25.3 g/t) and antimony (42.1%), demonstrating co-precipitation of both metals

Technical Achievement:

Both holes utilized precise wedge technology to achieve optimal vein intersections after initial deviations

Results bring project totals to 70 intersections >100 g/t AuEq x m and 74 intersections >50 to 100 g/t AuEq x m

Drill Hole Discussion

Results are reported from five diamond drill holes at the Rising Sun prospect:

SDDSC169, SDDSC169A, and SDDSC169AW1

SDDSC178 and SDDSC178W1

SDDSC169 Series: The original hole (SDDSC169) was abandoned early due to excessive deviation. A wedge hole (SDDSC169A) was drilled to maintain the planned infill spacing. This ultimately led to the successful third wedge (SDDSC169AW1).

SDDSC178 Series: SDDSC178 was drilled west to east, running sub-parallel to the main dyke and alteration zone but at a high angle to the mineralization and vein orientations. When the hole deviated too far from the target zone, it was abandoned. A wedge hole (SDDSC178W1) was then completed to achieve the planned infill spacing, resulting in successful intersections.

SDDSC169 SERIES

SDDSC169AW1 was drilled in a west to east orientation, sub-parallel to the main dyke and alteration package and at a high angle to mineralization and vein orientations.

SDDSC169AW1 intercepted seven vein sets in the Rising Sun system and confirmed exceptional high-grade continuity along strike within the RS15 vein structure (Figure 6). The hole returned 0.5 m @ 342.2 g/t AuEq (335.5 g/t Au, 2.8% Sb) from 615.7 m, located just 12 m along strike from SDDSC118 which previously reported 0.7 m @ 604.0 g/t AuEq (604.0 g/t Au, 0.0% Sb) from 555.7 m (reported June 13, 2024). The continuity of extremely high-grade mineralization confirms the robust nature of the RS15 vein system.

Drill hole highlights from SDDSC169AW1 include:

5.9 m @ 4.6 g/t AuEq (3.6 g/t Au, 0.4% Sb) from 550.3 m, including:

1.4 m @ 12.6 g/t AuEq (9.3 g/t Au, 1.4% Sb) from 554.8 m

3.4 m @ 1.4 g/t AuEq (1.3 g/t Au, 0.1% Sb) from 572.0 m

0.5 m @ 342.2 g/t AuEq (335.5 g/t Au, 2.8% Sb) from 615.73 m, including:

0.3 m @ 603.3 g/t AuEq (592.0 g/t Au, 4.7% Sb) from 615.98 m

2.8 m @ 2.0 g/t AuEq (0.8 g/t Au, 0.5% Sb) from 632.06 m

8.9 m @ 1.5 g/t AuEq (0.6 g/t Au, 0.4% Sb) from 678.78 m

6.1 m @ 3.4 g/t AuEq (3.0 g/t Au, 0.2% Sb) from 693.87 m, including:

0.1 m @ 117.4 g/t AuEq (116.0 g/t Au, 0.6% Sb) from 699.82 m

5.7 m @ 0.9 g/t AuEq (0.5 g/t Au, 0.2% Sb) from 704.27 m

1.2 m @ 5.2 g/t AuEq (3.9 g/t Au, 0.6% Sb) from 719.61 m

The intersection of multiple mineralized zones across significant intervals, combined with the high-grade cores, demonstrates the potential for both selective high-grade mining and bulk mining scenarios at Rising Sun.

SDDSC178 SERIES

SDDSC178W1 intercepted nine vein sets in the Rising Sun system, demonstrating the extensive stacked nature of mineralization. Remarkably, three individual assays reported antimony grades exceeding 40%, including 0.13 m at 43.8 % Sb and 3.15 g/t Au from 589.84 m and 0.13 m at 42.1 % Sb and 25.3 g/t Au from 524.66 m. These extraordinary antimony grades approach theoretical pure stibnite (Sb₂S₃ = ~71% Sb) and highlight Rising Sun's potential to supply critical antimony to Western markets.

Drill hole highlights from SDDSC178W1 include:

0.6 m @ 51.5 g/t AuEq (30.2 g/t Au, 8.9% Sb) from 434.3 m

0.5 m @ 8.0 g/t AuEq (6.5 g/t Au, 0.6% Sb) from 526.99 m

1.2 m @ 13.9 g/t AuEq (2.9 g/t Au, 4.6% Sb) from 523.99 m, including:

0.1 m @ 125.9 g/t AuEq (25.3 g/t Au, 42.1% Sb) from 524.66 m

0.4 m @ 12.2 g/t AuEq (8.4 g/t Au, 1.6% Sb) from 528.67 m

1.0 m @ 5.3 g/t AuEq (4.3 g/t Au, 0.4% Sb) from 540.62 m

2.6 m @ 1.1 g/t AuEq (0.8 g/t Au, 0.1% Sb) from 542.96 m

1.1 m @ 5.4 g/t AuEq (4.9 g/t Au, 0.2% Sb) from 567.91 m

18.0 m @ 3.7 g/t AuEq (1.6 g/t Au, 0.9% Sb) from 574.75 m, including:

0.6 m @ 17.7 g/t AuEq (14.9 g/t Au, 1.2% Sb) from 580.0 m

1.5 m @ 9.0 g/t AuEq (4.1 g/t Au, 2.1% Sb) from 582.17 m

0.2 m @ 51.4 g/t AuEq (3.6 g/t Au, 20.0% Sb) from 584.69 m

1.3 m @ 14.1 g/t AuEq (2.0 g/t Au, 5.1% Sb) from 588.85 m

2.4 m @ 1.6 g/t AuEq (0.6 g/t Au, 0.4% Sb) from 596.0 m

5.8 m @ 1.2 g/t AuEq (1.1 g/t Au, 0.0% Sb) from 670.0 m

The 18 m mineralized envelope containing multiple high-grade cores exemplifies Sunday Creek's characteristic mineralization style, where broader zones of economic mineralization host spectacular high-grade shoots.

Pending Results and Program Update

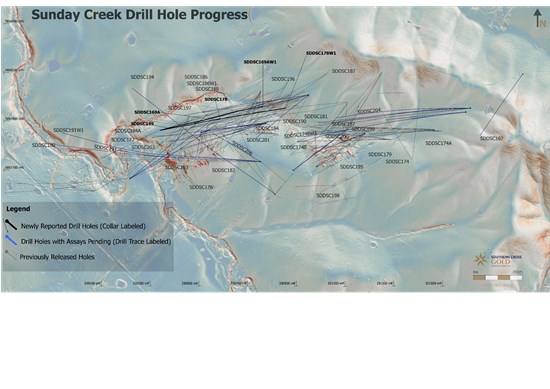

Results are pending from 32 holes currently being processed and analyzed including nine holes that are actively being drilled and four abandoned holes, with nine rigs actively drilling. The Company continues its 200,000 m drill program through Q1 2027.

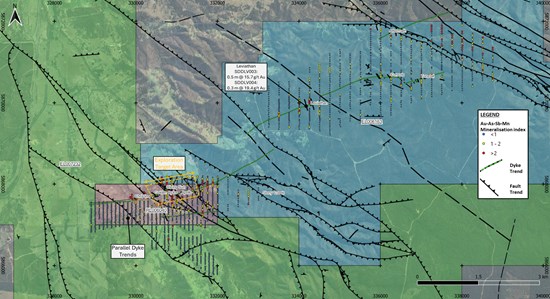

About Sunday Creek

The Sunday Creek epizonal-style gold project is located 60 km north of Melbourne within 16,900 hectares ("Ha") of granted exploration tenements. SXGC is also the freehold landholder of 1,054.51 Ha that forms the key portion in and around the main drilled area at the Sunday Creek Project.

Cumulatively, 220 drill holes for 97,553.07 m have been reported from Sunday Creek since late 2020. This amount includes five holes for 929 m that have been drilled for geotechnical purposes and 19 holes for 2,120.27 m that were abandoned due to deviation or hole conditions. Fourteen drillholes for 2,383 m have been reported regionally outside of the main Sunday Creek drill area. A total of 64 historic drill holes for 5,599 m were completed from the late 1960s to 2008. The project now contains a total of Seventy (70) >100 g/t AuEq x m and seventy-four (74) >50 to 100 g/t AuEq x m drill holes by applying a 2 m @ 1 g/t AuEq lower cut.

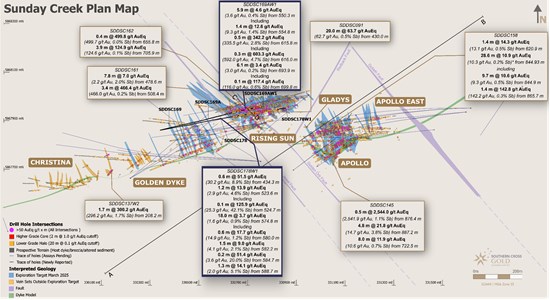

Our systematic drill program is strategically targeting these significant high-grade vein formations. Initially these have been defined over 1,500 m strike of the host from Christina to Apollo prospects, of which approximately 620 m have been more intensively drill tested (Rising Sun to Apollo). At least 83 'rungs' have been defined to date, defined by high-grade intercepts (20 g/t to >7,330 g/t Au) along with lower grade edges. Ongoing step-out drilling is aiming to uncover the potential extent of this mineralized system (Figures 1 to 3).

Geologically, the project is located within the Melbourne Structural Zone in the Lachlan Fold Belt. The regional host to the Sunday Creek mineralization is an interbedded turbidite sequence of siltstones and minor sandstones metamorphosed to sub-greenschist facies and folded into a set of open north-west trending folds.

Further Information

Further discussion and analysis of the Sunday Creek project is available through the interactive Vrify 3D animations, presentations and videos all available on the SXGC website. These data, along with an interview on these results with Michael Hudson, President & CEO, can be viewed at www.southerncrossgold.com.

No upper gold grade cut is applied in the averaging and intervals are reported as drill thickness. However, during future Mineral Resource studies, the requirement for assay top cutting will be assessed. The Company notes that due to rounding of assay results to one significant figure, minor variations in calculated composite grades may occur.

Figures 1 to 6 show project location, plan, longitudinal views and analysis of drill results reported here and Tables 1 to 3 provide collar and assay data. The true thickness of the mineralized intervals reported is approximately 60% to 90% of the sampled thickness for other reported holes. Lower grades were cut at 1.0 g/t AuEq lower cutoff over a maximum width of 2 m with higher grades cut at 5.0 g/t AuEq lower cutoff over a maximum of 1 m width.

Critical Metal Epizonal Gold-Antimony Deposits

Sunday Creek is an epizonal gold-antimony deposit formed in the late Devonian (like Fosterville, Costerfield and Redcastle), 60 million years later than mesozonal gold systems formed in Victoria (for example Ballarat and Bendigo). Epizonal deposits are a form of orogenic gold deposit classified according to their depth of formation: epizonal (<6 km), mesozonal (6-12 km) and hypozonal (>12 km).

Epizonal deposits in Victoria often have associated high levels of the critical metal, antimony, and Sunday Creek is no exception. China claims a 56 per cent share of global mined supplies of antimony, according to a 2023 European Union study. Antimony features highly on the critical minerals lists of many countries including Australia, the United States of America, Canada, Japan and the European Union. Australia ranks seventh for antimony production despite all production coming from a single mine at Costerfield in Victoria, located nearby to all SXG projects. Antimony alloys with lead and tin which results in improved properties for solders, munitions, bearings and batteries. Antimony is a prominent additive for halogen-containing flame retardants. Adequate supplies of antimony are critical to the world's energy transition, and to the high-tech industry, especially the semi-conductor and defence sectors where it is a critical additive to primers in munitions.

Antimony represents approximately 21% to 24% in situ recoverable value of Sunday Creek at an AuEq of 2.39 ratio.

In August 2024, the Chinese government announced it would place export limits from September 15, 2024 on antimony and antimony products. This puts pressure on Western defence supply chains and negatively affects the supply of the metal and pushes up pricing given China's dominance of the supply of the metal in the global markets. This is positive for SXGC as we are likely to have one of the very few large and high-quality projects of antimony in the western world that can feed western demand into the future.

About Southern Cross Gold Consolidated Ltd. (TSX: SXGC) (ASX: SX2) (OTCQX: SXGCF)

Southern Cross Gold Consolidated Ltd. (TSX: SXGC) (ASX: SX2) (OTCQX: SXGCF) controls the Sunday Creek Gold-Antimony Project located 60 km north of Melbourne, Australia. Sunday Creek has emerged as one of the Western world's most significant gold and antimony discoveries, with exceptional drilling results including 70 intersections exceeding 100 g/t AuEq x m from just 97.5 km of drilling. The mineralization follows a "Golden Ladder" structure over 12 km of strike length, with confirmed continuity from surface to 1,100 m depth.

Sunday Creek's strategic value is enhanced by its dual-metal profile, with antimony contributing approximately 20 % of the in-situ value alongside gold, meaning Importantly, Sunday Creek can be developed primarily based on gold economics, which reduces antimony-related risks while maintaining strategic supply potential. This has gained increased significance following China's export restrictions on antimony, a critical metal for defense and semiconductor applications. Southern Cross' inclusion in the US Defense Industrial Base Consortium (DIBC) and Australia's AUKUS-related legislative changes position it as a potential key Western antimony supplier.

Technical fundamentals further strengthen the investment case, with preliminary metallurgical work showing non-refractory mineralization suitable for conventional processing and gold recoveries of 93-98% through gravity and flotation.

With a strong cash position, over 1,000 Ha of strategic freehold land ownership, and a large 200 km drill program planned through Q1 2027, SXGC is well-positioned to advance this globally significant gold-antimony discovery in a tier-one jurisdiction.

NI 43-101 Technical Background and Qualified Person

Michael Hudson, President and CEO and Managing Director of SXGC, and a Fellow of the Australasian Institute of Mining and Metallurgy, and Mr Kenneth Bush, Exploration Manager of SXGC and a RPGeo (10315) of the Australian Institute of Geoscientists, are the Qualified Persons as defined by the NI 43-101. They have prepared, reviewed, verified and approved the technical contents of this release.

Analytical samples are transported to the Bendigo facility of On Site Laboratory Services ("On Site") which operates under both an ISO 9001 and NATA quality systems. Samples were prepared and analyzed for gold using the fire assay technique (PE01S method; 25 g charge), followed by measuring the gold in solution with flame AAS equipment. Samples for multi-element analysis (BM011 and over-range methods as required) use aqua regia digestion and ICP-MS analysis. The QA/QC program of Southern Cross Gold consists of the systematic insertion of certified standards of known gold and antimony content, blanks within interpreted mineralized rock and quarter core duplicates. In addition, On Site inserts blanks and standards into the analytical process.

SXGC considers that both gold and antimony that are included in the gold equivalent calculation ("AuEq") have reasonable potential to be recovered and sold at Sunday Creek, given current geochemical understanding, historic production statistics and geologically analogous mining operations. Historically, ore from Sunday Creek was treated onsite or shipped to the Costerfield mine, located 54 km to the northwest of the project, for processing during WW1. The Costerfield mine corridor, now owned by Mandalay Resources Ltd contains two million ounces of equivalent gold (Mandalay Q3 2021 Results), and in 2020 was the sixth highest-grade global underground mine and a top 5 global producer of antimony.

SXGC considers that it is appropriate to adopt the same gold equivalent variables as Mandalay Resources Ltd in its 2024 End of Year Mineral Reserves and Resources Press Release, dated February 20, 2025. The gold equivalence formula used by Mandalay Resources was calculated using Costerfield's 2024 production costs, using a gold price of US$2,500 per ounce, an antimony price of US$19,000 per tonne and 2024 total year metal recoveries of 91% for gold and 92% for antimony, and is as follows:

AuEq = Au (g/t) + 2.39 × Sb (%)

Based on the latest Costerfield calculation and given the similar geological styles and historic toll treatment of Sunday Creek mineralization at Costerfield, SXGC considers that a AuEq = Au (g/t) + 2.39 × Sb (%) is appropriate to use for the initial exploration targeting of gold-antimony mineralization at Sunday Creek.

JORC Competent Person Statement

Information in this announcement that relates to new exploration results contained in this report is based on information compiled by Mr Kenneth Bush and Mr Michael Hudson. Mr Bush is a Member of Australian Institute of Geoscientists and a Registered Professional Geologist and Member of the Australasian Institute of Mining and Metallurgy and Mr Hudson is a Fellow of The Australasian Institute of Mining and Metallurgy. Mr Bush and Mr Hudson each have sufficient experience relevant to the style of mineralization and type of deposit under consideration, and to the activities undertaken, to qualify as a Competent Person as defined in the 2012 Edition of the Joint Ore Reserves Committee (JORC) Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves. Mr Bush is Exploration Manager and Mr Hudson is President, CEO and Managing Director of Southern Cross Gold Consolidated Ltd. and both consent to the inclusion in the report of the matters based on their information in the form and context in which it appears.

Certain information in this announcement that relates to prior exploration results is extracted from the Independent Geologist's Report dated 11 December 2024 which was issued with the consent of the Competent Person, Mr Steven Tambanis. The report is included in the Company's prospectus dated 11 December 2024 and is available at www.asx.com.au under code "SX2". The Company confirms that it is not aware of any new information or data that materially affects the information related to exploration results included in the original market announcement. The Company confirms that the form and context of the Competent Persons' findings in relation to the report have not been materially modified from the original market announcement.

The Company confirms that it is not aware of any new information or data that materially affects the information included in the original document/announcement and the Company confirms that the form and context in which the Competent Person's findings are presented have not materially modified from the original market announcement.

- Ends -

This announcement has been approved for release by the Board of Southern Cross Gold Consolidated Ltd.

For further information, please contact:

Mariana Bermudez - Corporate Secretary - Canada

mbermudez@chasemgt.com or +1 604 685 9316

Executive Office: 1305 - 1090 West Georgia Street Vancouver, BC, V6E 3V7, Canada

Nicholas Mead - Corporate Development

info@southerncrossgold.com or +61 415 153 122

Justin Mouchacca, Company Secretary - Australia

jm@southerncrossgold.com.au or +61 3 8630 3321

Subsidiary Office: Level 21, 459 Collins Street, Melbourne, VIC, 3000, Australia

Forward-Looking Statement

This news release contains forward-looking statements. Forward-looking statements involve known and unknown risks, uncertainties and assumptions and accordingly, actual results and future events could differ materially from those expressed or implied in such statements. You are hence cautioned not to place undue reliance on forward-looking statements. All statements other than statements of present or historical fact are forward-looking statements. Forward-looking statements include words or expressions such as "proposed", "will", "subject to", "near future", "in the event", "would", "expect", "prepared to" and other similar words or expressions. Factors that could cause future results or events to differ materially from current expectations expressed or implied by the forward-looking statements include general business, economic, competitive, political, social uncertainties; the state of capital markets, unforeseen events, developments, or factors causing any of the expectations, assumptions, and other factors ultimately being inaccurate or irrelevant; and other risks described in the Company's documents filed with Canadian or Australian (under code SX2) securities regulatory authorities. You can find further information with respect to these and other risks in filings made by the Company with the securities regulatory authorities in Canada or Australia (under code SX2), as applicable, and available for the Company in Canada at www.sedarplus.ca or in Australia at www.asx.com.au (under code SX2). Documents are also available at www.southerncrossgold.com The Company disclaims any obligation to update or revise these forward-looking statements, except as required by applicable law.

Figure 1: Sunday Creek plan view showing selected results from holes SDDSC169, SDDSC169A, SDDSC169AW1, SDDSC178 and SDDSC178W1 reported here (dark blue highlighted box, black trace), with selected prior reported drill holes.

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/11541/268662_4ca3441c44f2a9de_005full.jpg

Figure 2: Sunday Creek plan view showing selected drillhole traces from holes SDDSC169, SDDSC169A, SDDSC169AW1, SDDSC178 and SDDSC178W1 reported here (black trace), with prior reported drill holes (grey trace) and currently drilling and assays pending hole traces (dark blue).

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/11541/268662_4ca3441c44f2a9de_006full.jpg

Figure 3: Sunday Creek longitudinal section across A-B in the plane of the dyke breccia/altered sediment host looking towards the north (striking 236 degrees) showing mineralized veins sets. Showing holes SDDSC169, SDDSC169A, SDDSC169AW1, SDDSC178 and SDDSC178W1 reported here (dark blue highlighted box, black trace), with selected intersections and prior reported drill holes. The vertical extents of the vein sets are limited by proximity to drill hole pierce points.

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/11541/268662_4ca3441c44f2a9de_007full.jpg

Figure 4: Sunday Creek regional plan view showing soil sampling, structural framework, regional historic epizonal gold mining areas and broad regional areas tested by 12 holes for 2,383 m drill program. The regional drill areas are at Tonstal, Consols and Leviathan located 4,000-7,500 m along strike from the main drill area at Golden Dyke-Apollo.

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/11541/268662_4ca3441c44f2a9de_008full.jpg

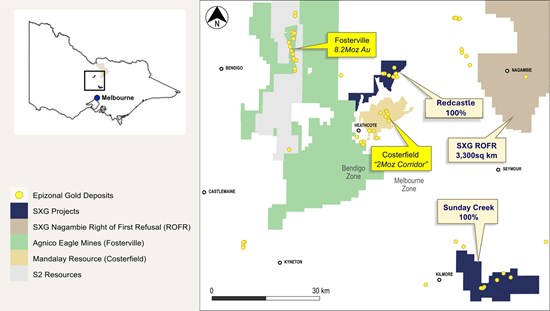

Figure 5: Location of the Sunday Creek project, along with the 100% owned Redcastle Gold-Antimony Project

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/11541/268662_4ca3441c44f2a9de_009full.jpg

Figure 6: Inclined long section (10 metres influence) across C-D in the plane of vein set RS15. Section strike 143 degrees.

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/11541/268662_4ca3441c44f2a9de_010full.jpg

Table 1: Drill collar summary table for recent drill holes in progress.

| This Release | |||||||

| Hole ID | Depth (m) | Prospect | East GDA94 Z55 | North GDA94 Z55 | Elevation (m) | Azimuth GDA94 Z55 | Dip |

| SDDSC169 | 68.6 | Rising Sun | 330340 | 5867861 | 276.7 | -54.6 | 76.3 |

| SDDSC169A | 354.95 | Rising Sun | 330340.1 | 5867861 | 276.8 | -54 | 76.1 |

| SDDSC169AW1 | 731.4 | Rising Sun | 330340.1 | 5867861 | 276.8 | -54 | 76.1 |

| SDDSC178 | 353.3 | Rising Sun | 330340.7 | 5867861 | 277 | -42.6 | 79.1 |

| SDDSC178W1 | 718 | Rising Sun | 330340.7 | 5867861 | 277 | -42.6 | 79.1 |

| Currently being processed and analysed | |||||||

| Hole ID | Depth (m) | Prospect | East GDA94 Z55 | North GDA94 Z55 | Elevation (m) | Azimuth GDA94 Z55 | Dip |

| SDDSC167 | 404.8 | Apollo East | 331830.3 | 5868092.4 | 347.9 | -37.9 | 216.9 |

| SDDSC176 | 865.8 | Golden Dyke | 330950.2 | 5868006.1 | 313.7 | -53.2 | 257.3 |

| SDDSC177 | 655.3 | Golden Dyke | 330774.9 | 5867890.7 | 295.2 | -52.2 | 258.1 |

| SDDSC179 | 448.8 | Apollo | 331465 | 5867862.9 | 333.2 | -38.6 | 265.4 |

| SDDSC180 | 1159.77 | Christina | 330753.2 | 5867732.9 | 306.8 | -45 | 273.1 |

| SDDSC181 | 1142.5 | Apollo | 331614.8 | 5867952.3 | 346.9 | -52.7 | 269.2 |

| SDDSC182 | 586.21 | Golden Dyke | 330219 | 5867664.1 | 268.9 | -41.6 | 60.8 |

| SDDSC174B | 912.5 | Apollo | 331596.2 | 5867936.2 | 345.5 | -41.6 | 263 |

| SDDSC183 | 343.1 | Christina | 329713.9 | 5867445.1 | 300.1 | -40 | 340.2 |

| SDDSC184A | 804 | Golden Dyke | 330775.1 | 5867890.9 | 295.3 | -54.8 | 263.2 |

| SDDSC186 | In Progress plan 900 m | Golden Dyke | 330950.5 | 5868006.3 | 313.8 | -54 | 262.6 |

| SDDSC187 | 518.3 | Rising Sun | 330510.7 | 5867852.7 | 295.4 | -50.5 | 75.4 |

| SDDSC186W1 | 774.1 | Golden Dyke | 330950.5 | 5868006.3 | 313.8 | -54 | 262.6 |

| SDDSC188 | 702 | Christina | 330218.3 | 5867664 | 268.9 | -50.5 | 57.9 |

| SDDSC190 | 451.8 | Rising Sun | 330511.4 | 5867852.5 | 295.5 | -40.8 | 80.1 |

| SDDSC192 | 1141 | Apollo | 331615.2 | 5867952.3 | 347 | -56.2 | 268.8 |

| SDDSC193 | 669 | Golden Dyke | 330775.4 | 5867891 | 295.5 | -58.6 | 262.2 |

| SDDSC194 | In Progress plan 1650 m | Golden Dyke | 330811.4 | 5867596.4 | 295.1 | -64.4 | 310 |

| SDDSC195 | 152.4 | Apollo | 330989.7 | 5867715.6 | 318 | -53.3 | 60.5 |

| SDDSC196 | In Progress plan 840 m | Rising Sun | 330484.2 | 5867893.4 | 289.5 | -64.4 | 74.8 |

| SDDSC197 | In Progress plan 820 m | Golden Dyke | 330217.8 | 5867664.2 | 268.9 | -58.7 | 50.8 |

| SDDSC198 | 275 | Apollo | 331180.4 | 5867849.1 | 306.1 | -31.5 | 248.6 |

| Hole ID | Depth (m) | Prospect | East GDA94 Z55 | North GDA94 Z55 | Elevation (m) | Azimuth GDA94 Z55 | Dip |

| SDDSC199 | In Progress plan 415 m | Apollo | 330887.5 | 5867704.5 | 312.7 | -42.8 | 52.2 |

| SDDSC201 | 320.4 | Rising Sun | 330948.3 | 5868003.4 | 313.3 | -28.9 | 231.3 |

| SDDSC174BW1 | In Progress plan 935 m | Apollo | 331596.2 | 5867936.2 | 345.5 | -41.6 | 263 |

| SDDSC191W1 | In Progress plan 1200 m | Christina | 330753.5 | 5867733 | 306.8 | -46.3 | 275.2 |

| SDDSC203 | In Progress plan 550 m | Golden Dyke | 330775.3 | 5867888.9 | 295.5 | -47.5 | 253.4 |

| SDDSC204 | In Progress plan 1210 m | Apollo | 331615.4 | 5867952.1 | 347 | -58.3 | 270.5 |

| Abandoned drillholes currently being processed and analysed | |||||||

| Hole ID | Depth (m) | Prospect | East GDA94 Z55 | North GDA94 Z55 | Elevation( m) | Dip | Azimuth GDA94 Z55 |

| SDDSC174 | 469.3 | Apollo | 331595.7 | 5867936 | 345.4 | -42.1 | 264.8 |

| SDDSC174A | 306.7 | Apollo | 331595.5 | 5867936 | 345.5 | -41.5 | 263.2 |

| SDDSC184 | 77.5 | Golden Dyke | 330775 | 5867891 | 295.4 | -56.5 | 259.2 |

| SDDSC191 | 864.4 | Christina | 330753.5 | 5867733 | 306.8 | -46.1 | 275.2 |

Table 2: Table of mineralized drill hole intersections reported from SDDSC169, SDDSC169A, SDDSC169AW1, SDDSC178 and SDDSC178W1 with two cutoff criteria. Lower grades cut at 1.0 g/t AuEq lower cutoff over a maximum of 2 m with higher grades cut at 5.0 g/t AuEq cutoff over a maximum of 1 m. Significant intersections and interval depths are rounded to one decimal place.

| Hole number | From (m) | To (m) | Interval (m) | Au g/t | Sb % | AuEq g/t |

| SDDSC169AW1 | 550.3 | 556.2 | 5.9 | 3.6 | 0.4 | 4.6 |

| Including | 554.8 | 556.2 | 1.4 | 9.3 | 1.4 | 12.6 |

| SDDSC169AW1 | 572 | 575.4 | 3.4 | 1.3 | 0.1 | 1.4 |

| SDDSC169AW1 | 615.75 | 616.25 | 0.5 | 335.5 | 2.8 | 342.2 |

| Including | 615.98 | 616.28 | 0.3 | 592.0 | 4.7 | 603.3 |

| SDDSC169AW1 | 632.06 | 634.86 | 2.8 | 0.8 | 0.5 | 2.0 |

| SDDSC169AW1 | 678.78 | 687.68 | 8.9 | 0.6 | 0.4 | 1.5 |

| SDDSC169AW1 | 693.87 | 699.97 | 6.1 | 3.0 | 0.2 | 3.4 |

| Including | 699.82 | 699.92 | 0.1 | 116.0 | 0.6 | 117.4 |

| SDDSC169AW1 | 704.27 | 709.97 | 5.7 | 0.5 | 0.2 | 0.9 |

| SDDSC169AW1 | 719.61 | 720.81 | 1.2 | 3.9 | 0.6 | 5.2 |

| SDDSC178W1 | 434.3 | 434.9 | 0.6 | 30.2 | 8.9 | 51.5 |

| SDDSC178W1 | 520.99 | 521.49 | 0.5 | 6.5 | 0.6 | 8.0 |

| SDDSC178W1 | 523.59 | 524.79 | 1.2 | 2.9 | 4.6 | 13.9 |

| Including | 524.66 | 524.76 | 0.1 | 25.3 | 42.1 | 125.9 |

| SDDSC178W1 | 528.67 | 529.07 | 0.4 | 8.4 | 1.6 | 12.2 |

| SDDSC178W1 | 540.62 | 541.62 | 1 | 4.3 | 0.4 | 5.3 |

| SDDSC178W1 | 542.96 | 545.56 | 2.6 | 0.8 | 0.1 | 1.1 |

| SDDSC178W1 | 567.91 | 569.01 | 1.1 | 4.9 | 0.2 | 5.4 |

| SDDSC178W1 | 574.75 | 592.75 | 18 | 1.6 | 0.9 | 3.7 |

| Including | 580 | 580.6 | 0.6 | 14.9 | 1.2 | 17.7 |

| Including | 582.17 | 583.67 | 1.5 | 4.1 | 2.1 | 9.0 |

| Including | 584.69 | 584.89 | 0.2 | 3.6 | 20.0 | 51.4 |

| Including | 588.65 | 589.95 | 1.3 | 2.0 | 5.1 | 14.1 |

| SDDSC178W1 | 596 | 598.4 | 2.4 | 0.6 | 0.4 | 1.6 |

| SDDSC178W1 | 670 | 675.8 | 5.8 | 1.1 | 0.0 | 1.2 |

Table 3: All individual assays reported from SDDSC169, SDDSC169A, SDDSC169AW1, SDDSC178 and SDDSC178W1 reported here >0.1g/t AuEq. Individual assay and sample intervals are reported to two decimal places.

| Hole number | From (m) | To (m) | Interval (m) | Au g/t | Sb % | AuEq g/t |

| SDDSC169AW1 | 420.99 | 421.45 | 0.46 | 0.12 | 0.00 | 0.13 |

| SDDSC169AW1 | 437.39 | 437.89 | 0.5 | 0.2 | 0.00 | 0.21 |

| SDDSC169AW1 | 437.89 | 438.03 | 0.14 | 0.13 | 0.02 | 0.18 |

| SDDSC169AW1 | 453.44 | 454.69 | 1.25 | 0.07 | 0.02 | 0.11 |

| SDDSC169AW1 | 454.69 | 455.6 | 0.91 | 0.15 | 0.03 | 0.21 |

| SDDSC169AW1 | 455.6 | 455.7 | 0.1 | 0.33 | 1.80 | 4.63 |

| SDDSC169AW1 | 455.7 | 455.87 | 0.17 | 0.34 | 0.03 | 0.42 |

| SDDSC169AW1 | 455.87 | 456.08 | 0.21 | 0.68 | 0.18 | 1.11 |

| SDDSC169AW1 | 499.8 | 500.9 | 1.1 | 0.17 | 0.01 | 0.18 |

| SDDSC169AW1 | 500.9 | 501.9 | 1 | 0.33 | 0.01 | 0.34 |

| SDDSC169AW1 | 523 | 524 | 1 | 0.1 | 0.01 | 0.12 |

| SDDSC169AW1 | 525.6 | 525.9 | 0.3 | 0.54 | 0.01 | 0.56 |

| SDDSC169AW1 | 525.9 | 526.6 | 0.7 | 0.67 | 0.01 | 0.69 |

| SDDSC169AW1 | 526.6 | 527 | 0.4 | 0.49 | 0.01 | 0.50 |

| SDDSC169AW1 | 527.7 | 527.9 | 0.2 | 3.18 | 0.02 | 3.22 |

| SDDSC169AW1 | 527.9 | 529 | 1.1 | 0.32 | 0.01 | 0.34 |

| SDDSC169AW1 | 532 | 533 | 1 | 0.33 | 0.03 | 0.41 |

| SDDSC169AW1 | 536.1 | 536.25 | 0.15 | 0.6 | 0.02 | 0.64 |

| SDDSC169AW1 | 538 | 539 | 1 | 0.15 | 0.01 | 0.17 |

| SDDSC169AW1 | 539.8 | 540.15 | 0.35 | 0.3 | 0.01 | 0.32 |

| SDDSC169AW1 | 540.15 | 540.6 | 0.45 | 0.52 | 0.04 | 0.61 |

| SDDSC169AW1 | 540.6 | 541 | 0.4 | 1.74 | 0.01 | 1.77 |

| SDDSC169AW1 | 543.8 | 544.25 | 0.45 | 0.21 | 0.01 | 0.23 |

| SDDSC169AW1 | 545.15 | 545.4 | 0.25 | 0.13 | 0.01 | 0.16 |

| SDDSC169AW1 | 545.9 | 546.3 | 0.4 | 0.93 | 0.46 | 2.03 |

| SDDSC169AW1 | 546.3 | 546.55 | 0.25 | 1.51 | 0.10 | 1.75 |

| SDDSC169AW1 | 546.55 | 546.9 | 0.35 | 0.25 | 0.02 | 0.29 |

| SDDSC169AW1 | 546.9 | 547.5 | 0.6 | 0.45 | 0.01 | 0.47 |

| SDDSC169AW1 | 547.5 | 547.8 | 0.3 | 0.25 | 0.01 | 0.27 |

| SDDSC169AW1 | 549.2 | 550.3 | 1.1 | 0.52 | 0.01 | 0.54 |

| SDDSC169AW1 | 550.3 | 550.75 | 0.45 | 5.59 | 0.08 | 5.78 |

| SDDSC169AW1 | 550.75 | 551.2 | 0.45 | 0.06 | 0.02 | 0.11 |

| SDDSC169AW1 | 551.2 | 551.4 | 0.2 | 2.64 | 1.46 | 6.13 |

| SDDSC169AW1 | 551.4 | 551.7 | 0.3 | 4.04 | 0.00 | 4.04 |

| SDDSC169AW1 | 551.7 | 552.7 | 1 | 0.11 | 0.02 | 0.15 |

| SDDSC169AW1 | 552.7 | 553.53 | 0.83 | 3.22 | 0.03 | 3.29 |

| SDDSC169AW1 | 553.53 | 553.7 | 0.17 | 3.6 | 1.38 | 6.90 |

| SDDSC169AW1 | 553.7 | 554 | 0.3 | 0.12 | 0.04 | 0.21 |

| SDDSC169AW1 | 554 | 554.45 | 0.45 | 0.36 | 0.02 | 0.40 |

| SDDSC169AW1 | 554.45 | 554.57 | 0.12 | 0.45 | 0.26 | 1.07 |

| SDDSC169AW1 | 554.57 | 554.8 | 0.23 | 0.96 | 0.19 | 1.41 |

| SDDSC169AW1 | 554.8 | 554.95 | 0.15 | 4.63 | 0.30 | 5.35 |

| SDDSC169AW1 | 554.95 | 555.4 | 0.45 | 0.34 | 0.10 | 0.58 |

| SDDSC169AW1 | 555.4 | 555.6 | 0.2 | 0.25 | 0.07 | 0.41 |

| SDDSC169AW1 | 555.6 | 555.8 | 0.2 | 0.62 | 0.48 | 1.77 |

| SDDSC169AW1 | 555.8 | 556 | 0.2 | 55.4 | 8.15 | 74.88 |

| SDDSC169AW1 | 556 | 556.2 | 0.2 | 4.37 | 0.47 | 5.49 |

| SDDSC169AW1 | 559.2 | 560 | 0.8 | 0.17 | 0.09 | 0.39 |

| SDDSC169AW1 | 560.5 | 561 | 0.5 | 1.13 | 0.55 | 2.44 |

| SDDSC169AW1 | 561 | 561.1 | 0.1 | 1.65 | 0.16 | 2.03 |

| SDDSC169AW1 | 566 | 567 | 1 | 0.08 | 0.03 | 0.15 |

| SDDSC169AW1 | 569 | 570 | 1 | 0.25 | 0.10 | 0.48 |

| SDDSC169AW1 | 572 | 573 | 1 | 3.04 | 0.06 | 3.18 |

| SDDSC169AW1 | 573 | 573.5 | 0.5 | 0.42 | 0.01 | 0.44 |

| SDDSC169AW1 | 573.5 | 573.7 | 0.2 | 0.61 | 0.02 | 0.65 |

| SDDSC169AW1 | 573.7 | 574.8 | 1.1 | 0.34 | 0.07 | 0.50 |

| SDDSC169AW1 | 574.8 | 575.4 | 0.6 | 0.96 | 0.06 | 1.11 |

| SDDSC169AW1 | 576.4 | 577 | 0.6 | 0.09 | 0.00 | 0.10 |

| SDDSC169AW1 | 583 | 584 | 1 | 0.1 | 0.01 | 0.12 |

| SDDSC169AW1 | 615.75 | 615.98 | 0.23 | 0.99 | 0.25 | 1.59 |

| SDDSC169AW1 | 615.98 | 616.28 | 0.3 | 592 | 4.72 | 603.28 |

| SDDSC169AW1 | 621.3 | 622 | 0.7 | 0.31 | 0.04 | 0.41 |

| SDDSC169AW1 | 622 | 622.45 | 0.45 | 0.33 | 0.33 | 1.12 |

| SDDSC169AW1 | 622.45 | 623.4 | 0.95 | 0.15 | 0.01 | 0.17 |

| SDDSC169AW1 | 623.4 | 624.2 | 0.8 | 0.08 | 0.01 | 0.10 |

| SDDSC169AW1 | 625.23 | 625.36 | 0.13 | 4.06 | 0.06 | 4.20 |

| SDDSC169AW1 | 625.36 | 626.32 | 0.96 | 0.57 | 0.38 | 1.48 |

| SDDSC169AW1 | 626.6 | 627.61 | 1.01 | 0.3 | 0.05 | 0.42 |

| SDDSC169AW1 | 628.05 | 629.32 | 1.27 | 0.36 | 0.03 | 0.43 |

| SDDSC169AW1 | 630.62 | 631.5 | 0.88 | 0.1 | 0.01 | 0.11 |

| SDDSC169AW1 | 632.06 | 632.22 | 0.16 | 0.37 | 0.71 | 2.07 |

| SDDSC169AW1 | 632.22 | 632.52 | 0.3 | 0.06 | 0.02 | 0.11 |

| SDDSC169AW1 | 632.52 | 632.91 | 0.39 | 2.2 | 0.15 | 2.56 |

| SDDSC169AW1 | 632.91 | 633.16 | 0.25 | 1.27 | 0.18 | 1.70 |

| SDDSC169AW1 | 633.16 | 633.47 | 0.31 | 1.86 | 1.71 | 5.95 |

| SDDSC169AW1 | 633.47 | 633.62 | 0.15 | 1 | 0.52 | 2.24 |

| SDDSC169AW1 | 633.62 | 634.4 | 0.78 | 0.3 | 0.45 | 1.38 |

| SDDSC169AW1 | 634.4 | 634.58 | 0.18 | 0.1 | 0.02 | 0.14 |

| SDDSC169AW1 | 634.58 | 634.82 | 0.24 | 0.41 | 0.48 | 1.56 |

| SDDSC169AW1 | 635.57 | 635.88 | 0.31 | 0.12 | 0.06 | 0.27 |

| SDDSC169AW1 | 636.99 | 637.19 | 0.2 | 0.24 | 0.41 | 1.22 |

| SDDSC169AW1 | 637.19 | 638.23 | 1.04 | 0.07 | 0.01 | 0.10 |

| SDDSC169AW1 | 638.23 | 638.37 | 0.14 | 0.31 | 0.02 | 0.36 |

| SDDSC169AW1 | 647.3 | 648.6 | 1.3 | 0.12 | 0.01 | 0.13 |

| SDDSC169AW1 | 648.6 | 649.9 | 1.3 | 0.04 | 0.04 | 0.15 |

| SDDSC169AW1 | 650.81 | 650.92 | 0.11 | 0.14 | 0.06 | 0.28 |

| SDDSC169AW1 | 661.1 | 662.15 | 1.05 | 0.1 | 0.00 | 0.11 |

| SDDSC169AW1 | 664.34 | 664.5 | 0.16 | -0.01 | 0.06 | 0.14 |

| SDDSC169AW1 | 665.8 | 667.1 | 1.3 | 0.05 | 0.03 | 0.13 |

| SDDSC169AW1 | 667.1 | 667.45 | 0.35 | 0.13 | 0.02 | 0.18 |

| SDDSC169AW1 | 668.11 | 668.21 | 0.1 | 0.17 | 0.26 | 0.79 |

| SDDSC169AW1 | 670 | 670.31 | 0.31 | 0.08 | 0.09 | 0.30 |

| SDDSC169AW1 | 671.24 | 672.32 | 1.08 | 0.05 | 0.04 | 0.14 |

| SDDSC169AW1 | 677.96 | 678.23 | 0.27 | 0.16 | 0.01 | 0.18 |

| SDDSC169AW1 | 678.23 | 678.78 | 0.55 | 0.24 | 0.20 | 0.72 |

| SDDSC169AW1 | 678.78 | 679.22 | 0.44 | 1.66 | 0.38 | 2.57 |

| SDDSC169AW1 | 679.22 | 679.35 | 0.13 | 0.89 | 0.22 | 1.42 |

| SDDSC169AW1 | 679.35 | 679.56 | 0.21 | 0.32 | 0.10 | 0.55 |

| SDDSC169AW1 | 679.56 | 679.98 | 0.42 | 0.28 | 0.09 | 0.50 |

| SDDSC169AW1 | 679.98 | 680.09 | 0.11 | 0.63 | 1.13 | 3.33 |

| SDDSC169AW1 | 680.09 | 680.28 | 0.19 | 0.22 | 0.08 | 0.40 |

| SDDSC169AW1 | 680.28 | 680.72 | 0.44 | 0.14 | 0.05 | 0.26 |

| SDDSC169AW1 | 680.72 | 680.82 | 0.1 | 0.26 | 0.08 | 0.45 |

| SDDSC169AW1 | 680.82 | 681.1 | 0.28 | 0.51 | 0.90 | 2.66 |

| SDDSC169AW1 | 681.1 | 681.7 | 0.6 | 0.29 | 0.31 | 1.03 |

| SDDSC169AW1 | 681.7 | 682.03 | 0.33 | 0.5 | 0.09 | 0.71 |

| SDDSC169AW1 | 682.03 | 682.13 | 0.1 | 1.12 | 0.10 | 1.36 |

| SDDSC169AW1 | 682.13 | 682.69 | 0.56 | 0.38 | 0.16 | 0.76 |

| SDDSC169AW1 | 682.69 | 683.03 | 0.34 | 0.37 | 0.27 | 1.02 |

| SDDSC169AW1 | 683.03 | 684 | 0.97 | 1.03 | 1.50 | 4.62 |

| SDDSC169AW1 | 684 | 684.83 | 0.83 | 0.47 | 0.08 | 0.66 |

| SDDSC169AW1 | 684.83 | 685.19 | 0.36 | 0.17 | 0.02 | 0.22 |

| SDDSC169AW1 | 685.19 | 685.6 | 0.41 | 0.8 | 0.26 | 1.42 |

| SDDSC169AW1 | 685.6 | 685.94 | 0.34 | 0.18 | 0.03 | 0.24 |

| SDDSC169AW1 | 685.94 | 686.53 | 0.59 | 0.51 | 0.20 | 0.99 |

| SDDSC169AW1 | 686.53 | 687.04 | 0.51 | 0.67 | 0.57 | 2.03 |

| SDDSC169AW1 | 687.04 | 687.15 | 0.11 | 1.11 | 1.70 | 5.17 |

| SDDSC169AW1 | 687.15 | 687.72 | 0.57 | 0.7 | 0.17 | 1.11 |

| SDDSC169AW1 | 687.72 | 687.83 | 0.11 | 0.15 | 0.04 | 0.25 |

| SDDSC169AW1 | 687.83 | 688.75 | 0.92 | 0.2 | 0.06 | 0.34 |

| SDDSC169AW1 | 689.2 | 689.77 | 0.57 | 0.35 | 0.07 | 0.51 |

| SDDSC169AW1 | 689.77 | 689.87 | 0.1 | 2.17 | 0.06 | 2.31 |

| SDDSC169AW1 | 689.87 | 690.75 | 0.88 | 0.23 | 0.04 | 0.33 |

| SDDSC169AW1 | 692.55 | 693.12 | 0.57 | 0.19 | 0.07 | 0.36 |

| SDDSC169AW1 | 693.12 | 693.87 | 0.75 | 0.21 | 0.03 | 0.28 |

| SDDSC169AW1 | 693.87 | 694 | 0.13 | 10 | 1.15 | 12.75 |

| SDDSC169AW1 | 694 | 694.4 | 0.4 | 0.36 | 0.08 | 0.55 |

| SDDSC169AW1 | 694.4 | 695.24 | 0.84 | 0.1 | 0.03 | 0.16 |

| SDDSC169AW1 | 695.24 | 695.37 | 0.13 | 1.37 | 0.27 | 2.02 |

| SDDSC169AW1 | 695.37 | 695.73 | 0.36 | 0.58 | 0.68 | 2.21 |

| SDDSC169AW1 | 695.73 | 696.6 | 0.87 | 0.18 | 0.04 | 0.27 |

| SDDSC169AW1 | 696.6 | 697.76 | 1.16 | 0.87 | 0.11 | 1.13 |

| SDDSC169AW1 | 697.76 | 698.41 | 0.65 | 1.23 | 0.49 | 2.40 |

| SDDSC169AW1 | 698.41 | 699.28 | 0.87 | 0.13 | 0.06 | 0.28 |

| SDDSC169AW1 | 699.28 | 699.68 | 0.4 | 0.13 | 0.01 | 0.16 |

| SDDSC169AW1 | 699.68 | 699.82 | 0.14 | 1.44 | 0.27 | 2.09 |

| SDDSC169AW1 | 699.82 | 699.94 | 0.12 | 116 | 0.57 | 117.36 |

| SDDSC169AW1 | 699.94 | 700.61 | 0.67 | 0.17 | 0.13 | 0.48 |

| SDDSC169AW1 | 700.61 | 701.61 | 1 | 0.12 | 0.04 | 0.22 |

| SDDSC169AW1 | 702.63 | 703.46 | 0.83 | 0.08 | 0.02 | 0.12 |

| SDDSC169AW1 | 703.46 | 704.27 | 0.81 | 0.37 | 0.13 | 0.68 |

| SDDSC169AW1 | 704.27 | 704.42 | 0.15 | 1.36 | 0.31 | 2.10 |

| SDDSC169AW1 | 704.42 | 704.87 | 0.45 | 0.57 | 0.36 | 1.43 |

| SDDSC169AW1 | 704.87 | 705.38 | 0.51 | 0.18 | 0.15 | 0.54 |

| SDDSC169AW1 | 705.38 | 705.8 | 0.42 | 0.09 | 0.03 | 0.16 |

| SDDSC169AW1 | 705.8 | 706.96 | 1.16 | 0.69 | 0.29 | 1.38 |

| SDDSC169AW1 | 706.96 | 707.06 | 0.1 | 1.67 | 1.15 | 4.42 |

| SDDSC169AW1 | 707.06 | 708.3 | 1.24 | 0.23 | 0.03 | 0.31 |

| SDDSC169AW1 | 708.3 | 709 | 0.7 | 0.24 | 0.10 | 0.48 |

| SDDSC169AW1 | 709 | 710 | 1 | 0.59 | 0.21 | 1.09 |

| SDDSC169AW1 | 710 | 710.32 | 0.32 | 0.09 | 0.03 | 0.15 |

| SDDSC169AW1 | 710.32 | 710.64 | 0.32 | 0.2 | 0.16 | 0.58 |

| SDDSC169AW1 | 714.6 | 715.86 | 1.26 | 0.1 | 0.06 | 0.25 |

| SDDSC169AW1 | 715.86 | 716.45 | 0.59 | 0.54 | 0.28 | 1.21 |

| SDDSC169AW1 | 716.45 | 716.84 | 0.39 | 0.32 | 0.15 | 0.68 |

| SDDSC169AW1 | 716.84 | 716.94 | 0.1 | 0.77 | 0.76 | 2.59 |

| SDDSC169AW1 | 716.94 | 717.68 | 0.74 | 0.39 | 0.15 | 0.75 |

| SDDSC169AW1 | 717.68 | 718.52 | 0.84 | 0.47 | 0.08 | 0.66 |

| SDDSC169AW1 | 719.61 | 720.28 | 0.67 | 0.97 | 0.36 | 1.83 |

| SDDSC169AW1 | 720.28 | 720.8 | 0.52 | 7.67 | 0.83 | 9.65 |

| SDDSC169AW1 | 721.38 | 722 | 0.62 | 0.25 | 0.02 | 0.30 |

| SDDSC169AW1 | 722 | 722.35 | 0.35 | 0.14 | 0.02 | 0.19 |

| SDDSC169AW1 | 724.62 | 725.65 | 1.03 | 0.82 | 0.23 | 1.37 |

| SDDSC169AW1 | 726.95 | 727.42 | 0.47 | 0.71 | 0.17 | 1.12 |

| SDDSC169AW1 | 728 | 729 | 1 | 0.11 | 0.02 | 0.16 |

| SDDSC178 | 194.52 | 194.85 | 0.33 | 0.48 | 0.00 | 0.48 |

| SDDSC178W1 | 419.74 | 419.84 | 0.1 | 0.13 | 4.80 | 11.60 |

| SDDSC178W1 | 422 | 423 | 1 | 0.13 | 0.01 | 0.15 |

| SDDSC178W1 | 423 | 424 | 1 | 1.79 | 0.01 | 1.81 |

| SDDSC178W1 | 425 | 426 | 1 | 0.1 | 0.01 | 0.12 |

| SDDSC178W1 | 426 | 427 | 1 | 0.15 | 0.01 | 0.18 |

| SDDSC178W1 | 428 | 429 | 1 | 0.22 | 0.01 | 0.24 |

| SDDSC178W1 | 431 | 432 | 1 | 0.22 | 0.00 | 0.23 |

| SDDSC178W1 | 433 | 433.6 | 0.6 | 0.19 | 0.01 | 0.21 |

| SDDSC178W1 | 434.3 | 434.7 | 0.4 | 10.3 | 2.80 | 16.99 |

| SDDSC178W1 | 434.7 | 434.86 | 0.16 | 80.1 | 24.10 | 137.70 |

| SDDSC178W1 | 436.9 | 437.7 | 0.8 | 0.16 | 0.00 | 0.17 |

| SDDSC178W1 | 446 | 447 | 1 | 0.24 | 0.01 | 0.25 |

| SDDSC178W1 | 455.46 | 456.76 | 1.3 | 0.09 | 0.02 | 0.13 |

| SDDSC178W1 | 461.96 | 463.26 | 1.3 | 0.28 | 0.01 | 0.30 |

| SDDSC178W1 | 463.26 | 464.25 | 0.99 | 0.1 | 0.01 | 0.13 |

| SDDSC178W1 | 464.25 | 464.52 | 0.27 | 1.58 | 0.16 | 1.96 |

| SDDSC178W1 | 464.52 | 465.82 | 1.3 | 0.34 | 0.05 | 0.45 |

| SDDSC178W1 | 465.82 | 467.12 | 1.3 | 0.23 | 0.01 | 0.25 |

| SDDSC178W1 | 468.42 | 469.1 | 0.68 | 0.29 | 0.01 | 0.30 |

| SDDSC178W1 | 469.1 | 469.5 | 0.4 | 0.62 | 0.00 | 0.63 |

| SDDSC178W1 | 469.5 | 470.33 | 0.83 | 0.09 | 0.00 | 0.10 |

| SDDSC178W1 | 470.33 | 471.63 | 1.3 | 0.17 | 0.02 | 0.22 |

| SDDSC178W1 | 481.3 | 482.2 | 0.9 | 0.19 | 0.02 | 0.24 |

| SDDSC178W1 | 482.2 | 483.15 | 0.95 | 0.17 | 0.02 | 0.22 |

| SDDSC178W1 | 483.15 | 483.56 | 0.41 | 0.2 | 0.01 | 0.22 |

| SDDSC178W1 | 483.56 | 484.86 | 1.3 | 0.23 | 0.00 | 0.24 |

| SDDSC178W1 | 484.86 | 486.16 | 1.3 | 0.12 | 0.00 | 0.13 |

| SDDSC178W1 | 486.16 | 486.58 | 0.42 | 0.11 | 0.00 | 0.12 |

| SDDSC178W1 | 498.09 | 498.39 | 0.3 | 0.1 | 0.01 | 0.13 |

| SDDSC178W1 | 498.39 | 499.09 | 0.7 | 0.09 | 0.05 | 0.20 |

| SDDSC178W1 | 499.09 | 499.52 | 0.43 | 0.18 | 0.05 | 0.30 |

| SDDSC178W1 | 499.52 | 500.15 | 0.63 | 0.07 | 0.02 | 0.11 |

| SDDSC178W1 | 500.15 | 500.59 | 0.44 | 0.09 | 0.01 | 0.12 |

| SDDSC178W1 | 500.59 | 501.06 | 0.47 | 0.34 | 0.07 | 0.50 |

| SDDSC178W1 | 501.06 | 501.56 | 0.5 | 0.47 | 0.05 | 0.58 |

| SDDSC178W1 | 501.56 | 501.96 | 0.4 | 0.37 | 0.07 | 0.54 |

| SDDSC178W1 | 501.96 | 502.46 | 0.5 | 0.56 | 0.06 | 0.70 |

| SDDSC178W1 | 502.46 | 502.98 | 0.52 | 0.78 | 0.07 | 0.95 |

| SDDSC178W1 | 502.98 | 503.35 | 0.37 | 0.09 | 0.06 | 0.24 |

| SDDSC178W1 | 503.35 | 503.79 | 0.44 | 0.56 | 0.06 | 0.69 |

| SDDSC178W1 | 503.79 | 504.12 | 0.33 | 2.86 | 0.22 | 3.39 |

| SDDSC178W1 | 504.12 | 504.52 | 0.4 | 0.08 | 0.07 | 0.24 |

| SDDSC178W1 | 504.52 | 505 | 0.48 | 0.09 | 0.03 | 0.15 |

| SDDSC178W1 | 506.23 | 506.63 | 0.4 | 0.7 | 0.02 | 0.74 |

| SDDSC178W1 | 506.63 | 507.05 | 0.42 | 0.11 | 0.02 | 0.15 |

| SDDSC178W1 | 508.35 | 508.53 | 0.18 | 0.29 | 0.02 | 0.34 |

| SDDSC178W1 | 513.42 | 514.72 | 1.3 | 0.06 | 0.10 | 0.30 |

| SDDSC178W1 | 517.9 | 518.74 | 0.84 | 0.09 | 0.02 | 0.14 |

| SDDSC178W1 | 520.99 | 521.14 | 0.15 | 21.1 | 1.44 | 24.54 |

| SDDSC178W1 | 521.14 | 521.5 | 0.36 | 0.46 | 0.25 | 1.06 |

| SDDSC178W1 | 521.5 | 521.89 | 0.39 | 0.06 | 0.02 | 0.11 |

| SDDSC178W1 | 521.89 | 522.36 | 0.47 | 0.18 | 0.04 | 0.27 |

| SDDSC178W1 | 523.59 | 523.72 | 0.13 | 0.98 | 0.39 | 1.91 |

| SDDSC178W1 | 524.66 | 524.79 | 0.13 | 25.3 | 42.10 | 125.92 |

| SDDSC178W1 | 528.67 | 529.03 | 0.36 | 8.44 | 1.58 | 12.22 |

| SDDSC178W1 | 529.03 | 529.75 | 0.72 | 0.09 | 0.04 | 0.18 |

| SDDSC178W1 | 530.54 | 530.96 | 0.42 | 0.41 | 0.04 | 0.51 |

| SDDSC178W1 | 530.96 | 532.23 | 1.27 | 0.02 | 0.05 | 0.13 |

| SDDSC178W1 | 533.39 | 533.62 | 0.23 | 0.5 | 0.01 | 0.51 |

| SDDSC178W1 | 534.3 | 534.81 | 0.51 | 0.23 | 0.01 | 0.26 |

| SDDSC178W1 | 534.81 | 535.13 | 0.32 | 1.31 | 0.02 | 1.35 |

| SDDSC178W1 | 535.13 | 535.91 | 0.78 | 0.17 | 0.04 | 0.25 |

| SDDSC178W1 | 535.91 | 536.41 | 0.5 | 0.19 | 0.01 | 0.21 |

| SDDSC178W1 | 538.37 | 538.72 | 0.35 | 0.27 | 0.23 | 0.82 |

| SDDSC178W1 | 539.65 | 540.3 | 0.65 | 0.2 | 0.10 | 0.44 |

| SDDSC178W1 | 540.3 | 540.62 | 0.32 | 0.06 | 0.06 | 0.21 |

| SDDSC178W1 | 540.62 | 541.16 | 0.54 | 7.3 | 0.45 | 8.38 |

| SDDSC178W1 | 541.16 | 541.66 | 0.5 | 1.15 | 0.36 | 2.01 |

| SDDSC178W1 | 541.66 | 542.34 | 0.68 | 0.15 | 0.02 | 0.21 |

| SDDSC178W1 | 542.34 | 542.49 | 0.15 | 0.13 | 0.12 | 0.42 |

| SDDSC178W1 | 542.49 | 542.68 | 0.19 | 0.15 | 0.33 | 0.94 |

| SDDSC178W1 | 542.68 | 542.96 | 0.28 | 0.19 | 0.14 | 0.52 |

| SDDSC178W1 | 542.96 | 543.29 | 0.33 | 3.04 | 0.14 | 3.37 |

| SDDSC178W1 | 543.29 | 543.39 | 0.1 | 2.93 | 0.46 | 4.03 |

| SDDSC178W1 | 543.39 | 543.77 | 0.38 | 1.03 | 0.44 | 2.08 |

| SDDSC178W1 | 543.77 | 544.5 | 0.73 | 0.23 | 0.06 | 0.38 |

| SDDSC178W1 | 544.74 | 545.34 | 0.6 | 0.15 | 0.01 | 0.18 |

| SDDSC178W1 | 545.34 | 545.51 | 0.17 | 0.94 | 0.04 | 1.04 |

| SDDSC178W1 | 546.81 | 547.61 | 0.8 | 0.1 | 0.01 | 0.12 |

| SDDSC178W1 | 547.61 | 547.97 | 0.36 | 1.32 | 0.12 | 1.61 |

| SDDSC178W1 | 549.52 | 550.01 | 0.49 | 0.21 | 0.02 | 0.25 |

| SDDSC178W1 | 551.67 | 552.15 | 0.48 | 0.04 | 0.11 | 0.30 |

| SDDSC178W1 | 552.15 | 552.81 | 0.66 | 0.09 | 0.03 | 0.16 |

| SDDSC178W1 | 552.81 | 553 | 0.19 | 0.06 | 0.03 | 0.12 |

| SDDSC178W1 | 554.26 | 554.57 | 0.31 | 0.4 | 0.01 | 0.43 |

| SDDSC178W1 | 554.57 | 555.31 | 0.74 | 0.08 | 0.01 | 0.11 |

| SDDSC178W1 | 555.31 | 555.67 | 0.36 | 0.31 | 0.03 | 0.37 |

| SDDSC178W1 | 557.38 | 557.88 | 0.5 | 0.05 | 0.03 | 0.11 |

| SDDSC178W1 | 557.88 | 558.24 | 0.36 | 0.37 | 0.03 | 0.45 |

| SDDSC178W1 | 558.24 | 558.69 | 0.45 | 0.73 | 0.11 | 0.99 |

| SDDSC178W1 | 558.69 | 559.31 | 0.62 | 0.95 | 0.19 | 1.40 |

| SDDSC178W1 | 559.31 | 559.62 | 0.31 | 1.21 | 0.01 | 1.23 |

| SDDSC178W1 | 559.62 | 559.74 | 0.12 | 1.27 | 0.01 | 1.29 |

| SDDSC178W1 | 559.74 | 560.28 | 0.54 | 0.99 | 0.02 | 1.03 |

| SDDSC178W1 | 560.28 | 560.42 | 0.14 | 0.23 | 0.01 | 0.25 |

| SDDSC178W1 | 560.42 | 560.61 | 0.19 | 0.35 | 0.02 | 0.39 |

| SDDSC178W1 | 560.61 | 560.85 | 0.24 | 0.13 | 0.01 | 0.16 |

| SDDSC178W1 | 560.85 | 561.36 | 0.51 | 0.59 | 0.10 | 0.83 |

| SDDSC178W1 | 561.36 | 561.78 | 0.42 | 0.1 | 0.01 | 0.12 |

| SDDSC178W1 | 561.78 | 562.19 | 0.41 | 0.73 | 0.02 | 0.77 |

| SDDSC178W1 | 562.19 | 562.9 | 0.71 | 0.13 | 0.03 | 0.19 |

| SDDSC178W1 | 562.9 | 563 | 0.1 | 0.42 | 0.50 | 1.62 |

| SDDSC178W1 | 563 | 563.5 | 0.5 | 0.12 | 0.02 | 0.17 |

| SDDSC178W1 | 564 | 564.95 | 0.95 | 0.15 | 0.11 | 0.41 |

| SDDSC178W1 | 564.95 | 566.15 | 1.2 | 0.11 | 0.03 | 0.17 |

| SDDSC178W1 | 566.15 | 567 | 0.85 | 0.08 | 0.03 | 0.15 |

| SDDSC178W1 | 567 | 567.91 | 0.91 | 0.31 | 0.10 | 0.55 |

| SDDSC178W1 | 567.91 | 568.25 | 0.34 | 12.5 | 0.38 | 13.41 |

| SDDSC178W1 | 568.25 | 568.96 | 0.71 | 1.31 | 0.08 | 1.49 |

| SDDSC178W1 | 568.96 | 569.7 | 0.74 | 0.61 | 0.03 | 0.68 |

| SDDSC178W1 | 569.7 | 570.17 | 0.47 | 0.35 | 0.01 | 0.38 |

| SDDSC178W1 | 570.17 | 571 | 0.83 | 0.4 | 0.05 | 0.53 |

| SDDSC178W1 | 571 | 571.22 | 0.22 | 0.23 | 0.01 | 0.26 |

| SDDSC178W1 | 571.22 | 571.88 | 0.66 | 0.47 | 0.32 | 1.23 |

| SDDSC178W1 | 571.88 | 572.91 | 1.03 | 0.37 | 0.04 | 0.46 |

| SDDSC178W1 | 572.91 | 573.5 | 0.59 | 0.12 | 0.03 | 0.18 |

| SDDSC178W1 | 573.5 | 573.99 | 0.49 | 0.08 | 0.02 | 0.13 |

| SDDSC178W1 | 573.99 | 574.75 | 0.76 | 0.27 | 0.12 | 0.56 |

| SDDSC178W1 | 574.75 | 575.8 | 1.05 | 0.9 | 0.10 | 1.13 |

| SDDSC178W1 | 575.8 | 576.29 | 0.49 | 2.4 | 0.39 | 3.33 |

| SDDSC178W1 | 576.29 | 577.14 | 0.85 | 0.17 | 0.04 | 0.25 |

| SDDSC178W1 | 577.14 | 578 | 0.86 | 0.5 | 0.05 | 0.61 |

| SDDSC178W1 | 578 | 578.6 | 0.6 | 1.54 | 0.09 | 1.76 |

| SDDSC178W1 | 579.13 | 580 | 0.87 | 0.5 | 0.18 | 0.93 |

| SDDSC178W1 | 580 | 580.6 | 0.6 | 14.9 | 1.16 | 17.67 |

| SDDSC178W1 | 580.6 | 581.81 | 1.21 | 0.56 | 0.12 | 0.85 |

| SDDSC178W1 | 581.81 | 582.17 | 0.36 | 0.13 | 0.04 | 0.22 |

| SDDSC178W1 | 582.17 | 582.3 | 0.13 | 6.1 | 18.50 | 50.32 |

| SDDSC178W1 | 582.3 | 582.47 | 0.17 | 7.08 | 0.96 | 9.37 |

| SDDSC178W1 | 582.47 | 582.72 | 0.25 | 0.54 | 0.08 | 0.72 |

| SDDSC178W1 | 582.72 | 582.92 | 0.2 | 11.1 | 0.24 | 11.67 |

| SDDSC178W1 | 582.92 | 583.4 | 0.48 | 1.38 | 0.43 | 2.41 |

| SDDSC178W1 | 583.4 | 583.65 | 0.25 | 4.12 | 0.78 | 5.98 |

| SDDSC178W1 | 583.65 | 583.9 | 0.25 | 0.99 | 1.54 | 4.67 |

| SDDSC178W1 | 583.9 | 584.37 | 0.47 | 1.58 | 0.65 | 3.13 |

| SDDSC178W1 | 584.37 | 584.69 | 0.32 | 0.51 | 0.05 | 0.62 |

| SDDSC178W1 | 584.69 | 584.86 | 0.17 | 3.55 | 20.00 | 51.35 |

| SDDSC178W1 | 584.86 | 585.55 | 0.69 | 0.8 | 0.22 | 1.33 |

| SDDSC178W1 | 586.97 | 587.82 | 0.85 | 1.03 | 0.10 | 1.27 |

| SDDSC178W1 | 588.65 | 589.09 | 0.44 | 4.45 | 0.67 | 6.05 |

| SDDSC178W1 | 589.09 | 589.48 | 0.39 | 0.26 | 0.02 | 0.31 |

| SDDSC178W1 | 589.48 | 589.84 | 0.36 | 0.5 | 1.96 | 5.18 |

| SDDSC178W1 | 589.84 | 589.97 | 0.13 | 3.15 | 43.80 | 107.83 |

| SDDSC178W1 | 589.97 | 590.3 | 0.33 | 0.71 | 0.07 | 0.88 |

| SDDSC178W1 | 590.3 | 590.73 | 0.43 | 3.85 | 0.34 | 4.66 |

| SDDSC178W1 | 591.32 | 592.28 | 0.96 | 0.1 | 0.02 | 0.15 |

| SDDSC178W1 | 592.28 | 592.72 | 0.44 | 0.52 | 0.36 | 1.38 |

| SDDSC178W1 | 592.72 | 593.42 | 0.7 | 0.27 | 0.02 | 0.31 |

| SDDSC178W1 | 594.27 | 595.1 | 0.83 | 0.09 | 0.01 | 0.11 |

| SDDSC178W1 | 595.1 | 595.63 | 0.53 | 0.12 | 0.03 | 0.20 |

| SDDSC178W1 | 595.63 | 596 | 0.37 | 0.17 | 0.01 | 0.20 |

| SDDSC178W1 | 596 | 596.82 | 0.82 | 0.86 | 0.10 | 1.10 |

| SDDSC178W1 | 596.82 | 597.12 | 0.3 | 0.49 | 0.92 | 2.69 |

| SDDSC178W1 | 597.12 | 598.4 | 1.28 | 0.38 | 0.56 | 1.72 |

| SDDSC178W1 | 598.4 | 599.14 | 0.74 | 0.14 | 0.01 | 0.17 |

| SDDSC178W1 | 599.14 | 599.65 | 0.51 | 0.12 | 0.02 | 0.17 |

| SDDSC178W1 | 599.65 | 600 | 0.35 | 0.16 | 0.02 | 0.21 |

| SDDSC178W1 | 603.35 | 604 | 0.65 | 0.08 | 0.01 | 0.10 |

| SDDSC178W1 | 604.5 | 604.98 | 0.48 | 0.08 | 0.02 | 0.12 |

| SDDSC178W1 | 604.98 | 605.6 | 0.62 | 0.42 | 0.03 | 0.48 |

| SDDSC178W1 | 605.6 | 606.23 | 0.63 | 0.18 | 0.01 | 0.21 |

| SDDSC178W1 | 608.49 | 608.6 | 0.11 | 0.08 | 0.02 | 0.12 |

| SDDSC178W1 | 611 | 611.5 | 0.5 | 0.3 | 0.21 | 0.80 |

| SDDSC178W1 | 614 | 615 | 1 | 0.08 | 0.05 | 0.19 |

| SDDSC178W1 | 616 | 616.61 | 0.61 | 0.33 | 0.05 | 0.44 |

| SDDSC178W1 | 616.61 | 617.55 | 0.94 | 0.11 | 0.02 | 0.16 |

| SDDSC178W1 | 617.55 | 618.1 | 0.55 | 0.24 | 0.10 | 0.48 |

| SDDSC178W1 | 618.1 | 619 | 0.9 | 0.08 | 0.01 | 0.10 |

| SDDSC178W1 | 619 | 620 | 1 | 0.13 | 0.01 | 0.16 |

| SDDSC178W1 | 620 | 620.3 | 0.3 | 0.13 | 0.01 | 0.14 |

| SDDSC178W1 | 620.3 | 621 | 0.7 | 0.12 | 0.01 | 0.13 |

| SDDSC178W1 | 621 | 621.53 | 0.53 | 0.52 | 0.01 | 0.54 |

| SDDSC178W1 | 621.53 | 622 | 0.47 | 0.24 | 0.02 | 0.29 |

| SDDSC178W1 | 622 | 622.5 | 0.5 | 0.25 | 0.00 | 0.26 |

| SDDSC178W1 | 622.5 | 623.04 | 0.54 | 0.91 | 0.01 | 0.93 |

| SDDSC178W1 | 623.04 | 623.55 | 0.51 | 1.12 | 0.01 | 1.15 |

| SDDSC178W1 | 623.55 | 624.31 | 0.76 | 0.35 | 0.00 | 0.36 |

| SDDSC178W1 | 624.31 | 624.45 | 0.14 | 0.76 | 0.01 | 0.78 |

| SDDSC178W1 | 624.45 | 624.66 | 0.21 | 0.23 | 0.00 | 0.24 |

| SDDSC178W1 | 624.66 | 625.04 | 0.38 | 0.34 | 0.01 | 0.35 |

| SDDSC178W1 | 625.04 | 625.18 | 0.14 | 0.23 | 0.01 | 0.24 |

| SDDSC178W1 | 625.18 | 625.6 | 0.42 | 0.1 | 0.01 | 0.12 |

| SDDSC178W1 | 625.6 | 626.09 | 0.49 | 0.14 | 0.01 | 0.16 |

| SDDSC178W1 | 626.09 | 626.61 | 0.52 | 1.93 | 0.01 | 1.96 |

| SDDSC178W1 | 626.61 | 627.7 | 1.09 | 0.45 | 0.01 | 0.48 |

| SDDSC178W1 | 627.7 | 628.3 | 0.6 | 0.08 | 0.01 | 0.10 |

| SDDSC178W1 | 628.3 | 628.49 | 0.19 | 0.19 | 0.01 | 0.22 |

| SDDSC178W1 | 629.3 | 630 | 0.7 | 1.96 | 0.01 | 1.98 |

| SDDSC178W1 | 630 | 630.64 | 0.64 | 0.23 | 0.07 | 0.39 |

| SDDSC178W1 | 631.51 | 631.84 | 0.33 | 0.42 | 0.01 | 0.43 |

| SDDSC178W1 | 631.84 | 632.54 | 0.7 | 0.85 | 0.01 | 0.87 |

| SDDSC178W1 | 632.83 | 633.06 | 0.23 | 0.15 | 0.01 | 0.18 |

| SDDSC178W1 | 633.06 | 633.18 | 0.12 | 0.36 | 0.01 | 0.39 |

| SDDSC178W1 | 633.6 | 633.87 | 0.27 | 0.16 | 0.00 | 0.17 |

| SDDSC178W1 | 634.48 | 634.66 | 0.18 | 0.16 | 0.01 | 0.17 |

| SDDSC178W1 | 634.66 | 635.2 | 0.54 | 0.18 | 0.01 | 0.19 |

| SDDSC178W1 | 635.88 | 636.79 | 0.91 | 0.35 | 0.01 | 0.38 |

| SDDSC178W1 | 639.03 | 639.68 | 0.65 | 0.11 | 0.02 | 0.15 |

| SDDSC178W1 | 642.97 | 643.47 | 0.5 | 0.11 | 0.01 | 0.12 |

| SDDSC178W1 | 643.47 | 643.57 | 0.1 | 0.32 | 0.02 | 0.37 |

| SDDSC178W1 | 643.57 | 644.06 | 0.49 | 0.09 | 0.01 | 0.11 |

| SDDSC178W1 | 644.06 | 644.19 | 0.13 | 0.26 | 0.02 | 0.30 |

| SDDSC178W1 | 645.48 | 645.73 | 0.25 | 0.48 | 0.02 | 0.53 |

| SDDSC178W1 | 645.73 | 646.23 | 0.5 | 0.08 | 0.01 | 0.10 |

| SDDSC178W1 | 646.23 | 646.41 | 0.18 | 0.5 | 0.03 | 0.57 |

| SDDSC178W1 | 646.41 | 646.84 | 0.43 | 0.14 | 0.02 | 0.19 |

| SDDSC178W1 | 646.84 | 646.98 | 0.14 | 1.18 | 0.02 | 1.22 |

| SDDSC178W1 | 646.98 | 647.33 | 0.35 | 0.21 | 0.01 | 0.23 |

| SDDSC178W1 | 647.33 | 647.43 | 0.1 | 0.2 | 0.01 | 0.23 |

| SDDSC178W1 | 647.43 | 648.04 | 0.61 | 0.33 | 0.02 | 0.38 |

| SDDSC178W1 | 650.29 | 650.68 | 0.39 | 0.09 | 0.74 | 1.86 |

| SDDSC178W1 | 650.68 | 651.2 | 0.52 | 0.74 | 0.02 | 0.79 |

| SDDSC178W1 | 651.2 | 651.67 | 0.47 | 0.52 | 0.02 | 0.56 |

| SDDSC178W1 | 651.67 | 652.59 | 0.92 | 0.34 | 0.02 | 0.39 |

| SDDSC178W1 | 653.71 | 654.02 | 0.31 | 0.92 | 0.02 | 0.96 |

| SDDSC178W1 | 654.45 | 654.75 | 0.3 | 0.2 | 0.02 | 0.25 |

| SDDSC178W1 | 654.75 | 654.96 | 0.21 | 0.61 | 0.01 | 0.64 |

| SDDSC178W1 | 654.96 | 655.46 | 0.5 | 0.14 | 0.02 | 0.18 |

| SDDSC178W1 | 656.94 | 657.5 | 0.56 | 0.14 | 0.02 | 0.18 |

| SDDSC178W1 | 658.83 | 658.96 | 0.13 | 0.24 | 0.02 | 0.28 |

| SDDSC178W1 | 658.96 | 659.38 | 0.42 | 0.1 | 0.04 | 0.19 |

| SDDSC178W1 | 659.38 | 659.61 | 0.23 | 0.12 | 0.01 | 0.13 |

| SDDSC178W1 | 659.61 | 659.75 | 0.14 | 0.61 | 0.01 | 0.64 |

| SDDSC178W1 | 659.75 | 659.86 | 0.11 | 0.42 | 0.01 | 0.44 |

| SDDSC178W1 | 661.92 | 662.19 | 0.27 | 0.37 | 0.01 | 0.39 |

| SDDSC178W1 | 662.52 | 663 | 0.48 | 0.11 | 0.02 | 0.17 |

| SDDSC178W1 | 663 | 663.74 | 0.74 | 0.09 | 0.02 | 0.14 |

| SDDSC178W1 | 663.74 | 664.22 | 0.48 | 0.05 | 0.02 | 0.10 |

| SDDSC178W1 | 665.97 | 666.33 | 0.36 | 0.05 | 0.02 | 0.10 |

| SDDSC178W1 | 668 | 668.8 | 0.8 | 0.47 | 0.01 | 0.48 |

| SDDSC178W1 | 668.8 | 669 | 0.2 | 0.18 | 0.00 | 0.19 |

| SDDSC178W1 | 669 | 669.55 | 0.55 | 0.29 | 0.01 | 0.31 |

| SDDSC178W1 | 669.55 | 670 | 0.45 | 0.31 | 0.02 | 0.36 |

| SDDSC178W1 | 670 | 671 | 1 | 1.56 | 0.01 | 1.58 |

| SDDSC178W1 | 671 | 672 | 1 | 0.44 | 0.01 | 0.47 |

| SDDSC178W1 | 672 | 673 | 1 | 1.31 | 0.01 | 1.34 |

| SDDSC178W1 | 673 | 674 | 1 | 0.82 | 0.01 | 0.85 |

| SDDSC178W1 | 674 | 675 | 1 | 1.33 | 0.01 | 1.36 |

| SDDSC178W1 | 675 | 675.8 | 0.8 | 1.42 | 0.01 | 1.44 |

| SDDSC178W1 | 675.8 | 677 | 1.2 | 0.13 | 0.01 | 0.15 |

JORC Table 1

Section 1 Sampling Techniques and Data

| Criteria | JORC Code explanation | Commentary |

| Sampling techniques |

|

|

| Drilling techniques |

|

|

| Drill sample recovery |

|

|

| Logging |

|

|

| Sub-sampling techniques and sample preparation |

|

|

| Quality of assay data and laboratory tests |

|

|

| Verification of sampling and assaying |

|

|

| Location of data points |

|

|

| Data spacing and distribution |

|

|

| Orientation of data in relation to geological structure |

|

|

| Sample security |

|

|

| Audits or reviews |

|

|

Southern Cross Gold (SXG) ASX Announcement

Section 2 Reporting of Exploration Results

| Criteria | JORC Code explanation | Commentary |

| Mineral tenement and land tenure status |

|

|

| Exploration done by other parties |

|

|

| Geology |

|

|

| Drill hole Information |

|

|

| Data aggregation methods |

|

|

| Relationship between mineralization widths and intercept lengths |

|

|

| Diagrams |

|

|

| Balanced reporting |

|

|

| Other substantive exploration data |

|

|

| Further work |

|

|

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/268662