Want to curate the report according to your business needs

Report Description + Table of Content + Company Profiles

The global friction stir welding equipment market is expected to reach a substantially large market size in 2027 and register a high CAGR over the forecast period. Industry analysis indicates that rising demand for friction stir welding equipment in various end-use industries is driven by changing market trends, which are expected to support industry growth as well as market growth over the forecast period.

Welding is a process in which two metals are joined together through melting. Friction stir welding (FSW) is a solid-state welding process, wherein the metals are not melted. The process uses friction to heat the metal to just below its melting point, due to pressure caused by solid-state fusion. The friction stir welding equipment rotates at a high speed, which generates heat that causes the metals to fuse into each other. To carry out this process, skilled workforce is required. This welding technique is eco-friendly, energy-efficient, and versatile. Friction stir welding is capable of joining dissimilar Aluminum Alloys, Titanium alloys, mild Steel, copper alloys, Stainless Steel, and Magnesium Alloys.

Friction stir welding equipment are extensively used in the automotive industry for the aluminum welding process. This process imparts mechanical features to end-products such as strength, obstruction to weariness, and rigidity. This factor is expected to drive the friction stir welding equipment market growth over the forecast period. Use of friction stir welding equipment provides operating cost advantages, low impact on the environment, and limited impact on health. This drives use of friction stir welding equipment in several metal-processing applications.

Friction stir welding is an energy-efficient and eco-friendly technology, with no molten material or fumes involved in this process. It supports a wide range of thickness and it is useful in various end-use industries such as automotive, shipbuilding, aerospace, and railways. Being a solid-state process, friction stir welding eliminates numerous defects associated with the conventional fusion welding techniques, such as shrinkage, cracking, solidification, and porosity. This factor is expected to drive market growth in the next few years.

However, lack of skilled and qualified workforce is expected to hinder growth of the global friction stir welding equipment market over the forecast period.

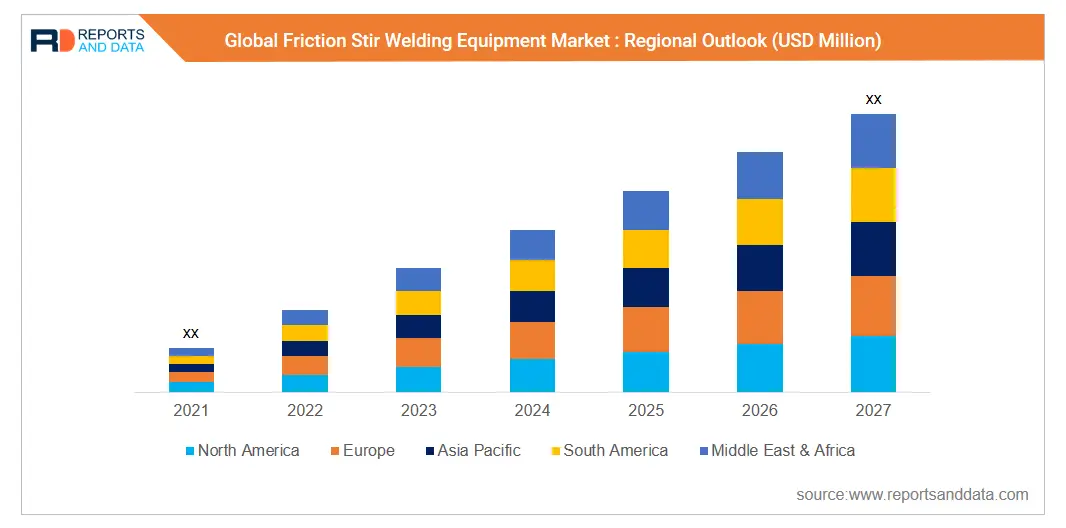

Based on region, the global friction stir welding equipment market has been segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Revenues from the friction stir welding equipment market in North America are expected to grow at a significantly high rate over the forecast period, due to increasing demand for friction stir welding equipment from the electronics sector, advancements in technology, and launch of innovative equipment in the region. Revenues from the Asia Pacific friction stir welding equipment market are also expected to increase at a high pace over the forecast period, due to growth of aerospace, railways, and automotive industries in the region.

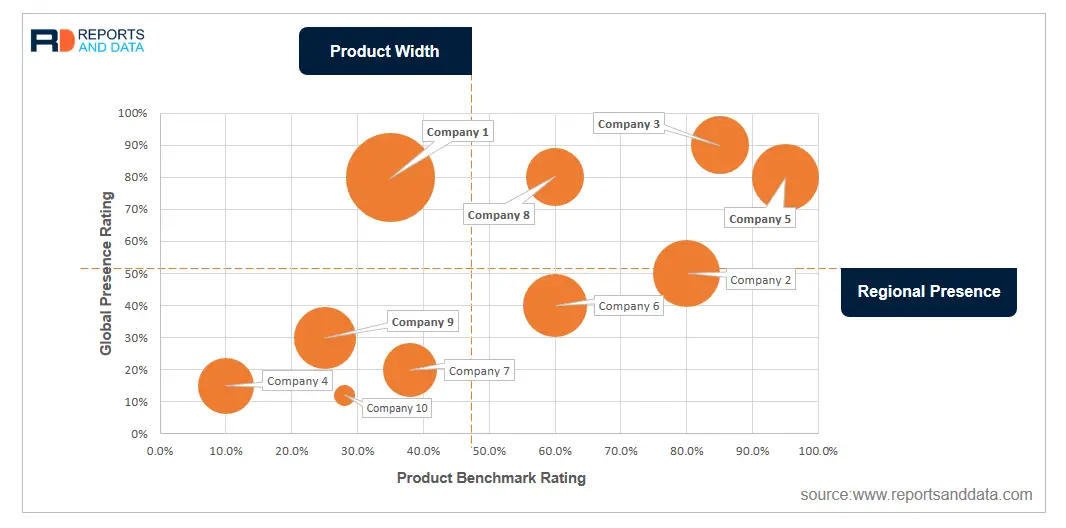

The report contains analysis of recent developments and trends in the global friction stir welding equipment market and strategies adopted by key players operating in the market. This also includes collaborations, business contracts, mergers and acquisitions, and joint ventures.

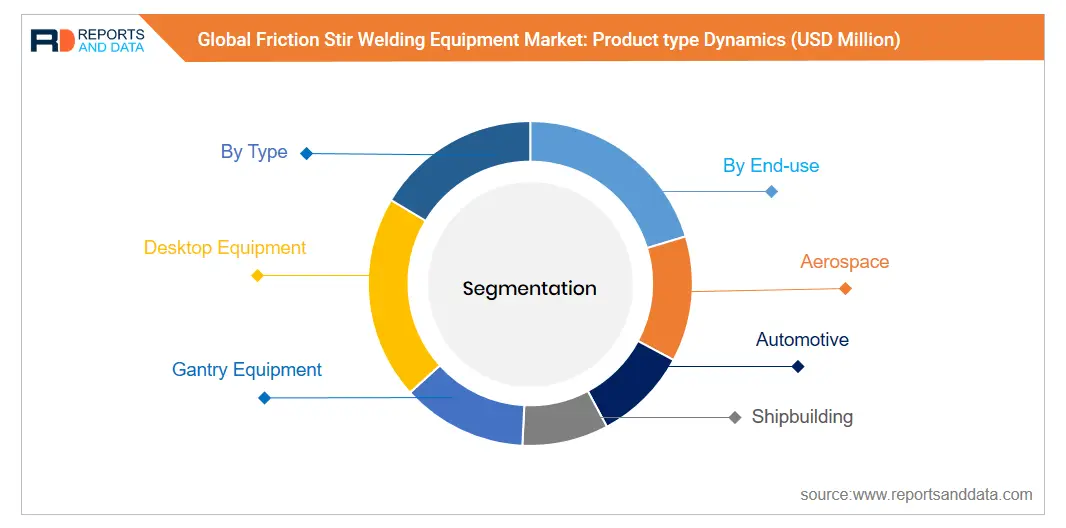

The report consists of forecasts for the friction stir welding equipment market at the global, regional, and country levels. The report contains analysis of market trends in each segment for the period from 2020 to 2027. For this study, Reports and Data has segmented the global friction stir welding equipment market based on type and end-use industry as follows.

Facing issues finding the exact research to meet your business needs? Let us help you! One of our Research Executives will help you locate the research study that will answer your concerns. Speak to Analyst Request for Customization

Request a FREE Sample here to understand what more we have to offer over competition…

upto20% OFF

upto20% OFF

Want to curate the report according to your business needs

Report Description + Table of Content + Company Profiles