Want to curate the report according to your business needs

Report Description + Table of Content + Company Profiles

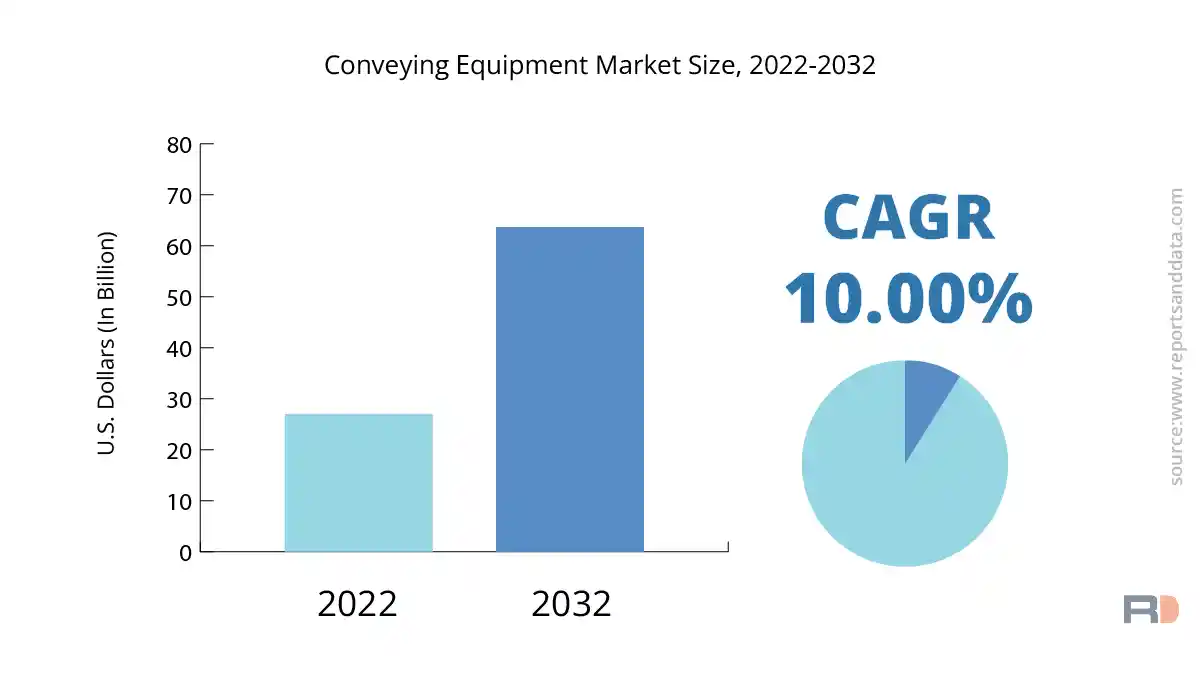

The market value for Conveying Equipment Market was USD 27 Billion in 2022 and is expected to reach USD 63.66 Billion in 2032 growing at a CAGR of 10% during the forecast period. Factors such as increased demand for effective material handling systems and the requirement for automation in various end-use sectors are driving market expansion. The rise in e-commerce operations, as well as the requirement for speedier delivery of goods, are also driving the expansion of the Conveying Equipment Market.

Rapid urbanization and infrastructure development in emerging economies have raised the need for conveying equipment in the construction industry. Conveying equipment is a vital component of the construction process since the construction industry demands a constant flow of materials to be carried from one site to another. Furthermore, the introduction of government rules about safety and the environment in the construction industry has raised the demand for conveying equipment, as it helps to reduce manual labor and contributes to a safer work environment.

Another important end-use business for conveying equipment is the food and beverage industry. Consumer awareness of food safety and quality is raising the demand for hygienic and efficient food-handling equipment. The use of automated conveying equipment in the food sector helps to maintain sanitary requirements while also reducing manual labor in the production process. This has increased demand for conveying equipment in the food and beverage industry, adding to market growth.

Furthermore, as the automobile sector expands, so does the demand for conveying equipment for material handling and assembly line activities. Conveying equipment assists in the effective transportation of materials in the automobile industry, leading to higher productivity and reduced downtime.

Mining is another important end-use industry for conveying equipment. The increased demand for minerals and metals has increased mining activity, necessitating the need for efficient material handling equipment. Conveying equipment is used in mining operations to transfer ores and minerals, minimizing manual labor and enhancing process efficiency.

Technological advances in the conveying equipment business, such as the usage of improved sensors and monitoring systems, have aided market expansion. The adoption of Industry 4.0 technology in the manufacturing process has resulted in the introduction of smart conveying equipment, which aids in real-time monitoring of the manufacturing process, resulting in enhanced efficiency and decreased downtime.

However, the market expansion is hampered by issues such as the high cost of installing and maintaining conveying equipment, as well as a lack of experienced labor required for the equipment’s operation and maintenance. Furthermore, the availability of low-cost alternatives in the market is projected to have an impact on market growth throughout the forecast period.

The global Conveying Equipment Market is divided into belt conveyors, roller conveyors, overhead conveyors, pneumatic conveyors, and others depending on product type. Because of its broad applicability in industries such as manufacturing, food and beverage, mining, and automotive, among others, the belt conveyor segment has the highest revenue share in the market. These conveyors are widely used for transporting bulk commodities and unit loads over long distances, and their appeal stems from their great load-carrying capacity, flexibility, and low maintenance cost. Furthermore, the development of novel and improved belt conveyor systems, such as modular belt conveyors and enclosed belt conveyors, is likely to drive this segment’s growth throughout the forecast period.

During the projection period, the roller conveyor segment is expected to increase significantly. Conveyors such as this are frequently utilized in material handling applications, notably for the movement of heavy products, and are found in industries such as automotive, pharmaceutical, and retail. The expansion of the e-commerce business has increased demand for roller conveyors, which are utilized in the packaging and shipping of goods. Furthermore, the introduction of modern technologies such as motorized roller conveyors and smart conveyor systems is likely to drive this segment’s growth throughout the forecast period.

During the projected period, the overhead conveyor segment is also expected to increase significantly. Conveyors of this type are commonly used in industries such as automotive, aerospace, and food and beverage to transport heavy and bulky items. In the approaching years, the introduction of innovative technologies such as automated overhead conveyor systems is projected to drive the expansion of this market.

During the projection period, the pneumatic conveyor segment is expected to increase steadily. These conveyors transfer products using air pressure and are commonly employed in industries such as food and beverage, chemical, and pharmaceutical. During the projected period, the rise of these industries, combined with the increasing demand for automation in material handling operations, is expected to fuel the growth of this segment.

The others conveyor segment, which comprises screw conveyors and vibrating conveyors, is predicted to develop moderately over the projection period. These conveyors are often used in the construction and mining industries for conveying large commodities.

In 2021, the manufacturing segment led the global Conveying Equipment Market, and this dominance is likely to continue over the forecast period.

The global Conveying Equipment Market has been categorized by end-use into manufacturing, food and beverage, mining, construction, and others. In 2021, the manufacturing segment had the highest revenue share in the global market. The segment is likely to maintain its dominance during the forecast period, owing to increased automation in manufacturing facilities, which has led to an increase in demand for efficient and dependable conveying equipment. Furthermore, growing concerns about workplace safety and the need to drive efficiency have prompted the use of modern conveying equipment in manufacturing plants. These reasons are projected to drive the manufacturing segment of the global Conveying Equipment Market forward.

During the projected period, the food and beverage segment is expected to have the highest CAGR. The increasing demand for packaged food goods, as well as the necessity for efficient and hygienic conveying equipment in the food and beverage industry, are driving the expansion of this market. Furthermore, the growing use of automation in the food and beverage industries is likely to drive up demand for conveying equipment. Furthermore, strict food safety and hygiene standards are projected to drive the usage of modern conveying equipment in the food and beverage industry.

During the forecast period, the mining segment is also expected to increase significantly. This segment’s expansion can be ascribed to the rising demand for minerals and metals, which has increased mining activity around the world. The demand for effective and dependable conveying equipment in mining operations to carry heavy commodities such as ores and minerals is likely to drive the global market expansion of this segment.

During the forecast period, the construction segment is expected to develop somewhat. This segment’s expansion can be attributable to the increased need for infrastructure development around the world, which has increased construction activity. The demand for conveying equipment in construction activities to carry materials such as concrete, bricks, and sand is likely to drive global market expansion in this segment.

During the projected period, the other segment, which comprises businesses such as healthcare, automotive, and retail, among others, is expected to increase steadily. The rising adoption of automation in various industries, as well as the necessity for efficient and dependable conveying equipment to drive productivity and safety, might be linked to the expansion of this market.

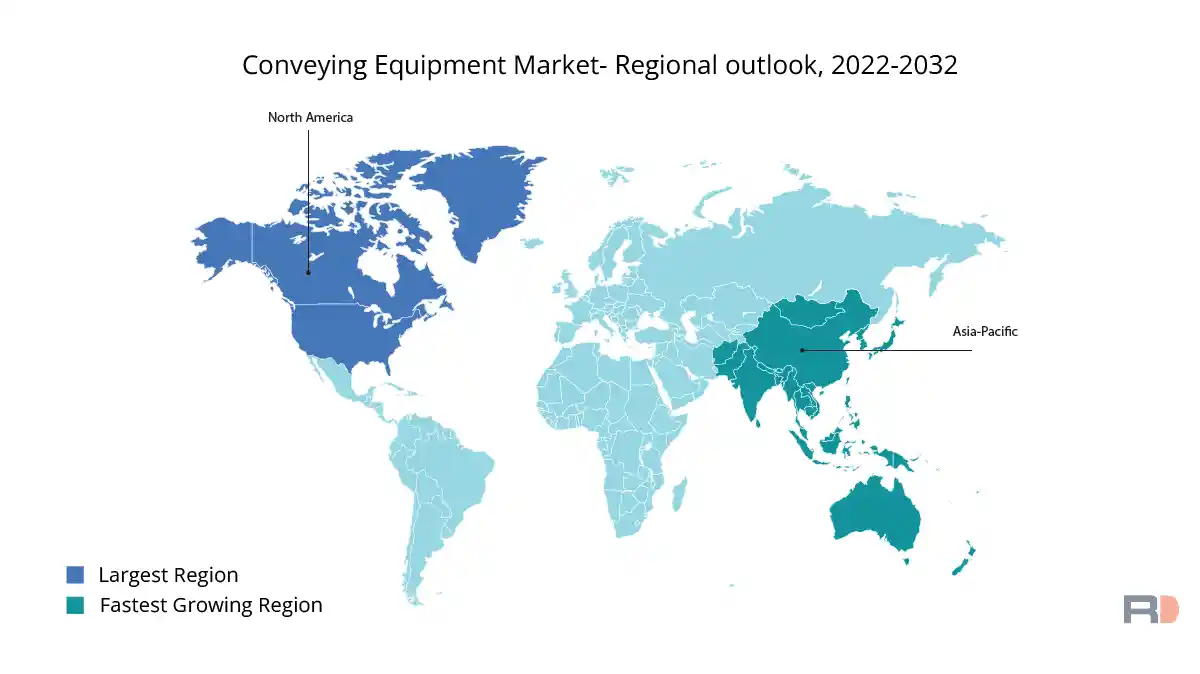

During the projected period, the North American market is expected to lead the global Conveying Equipment Market in terms of revenue share. The region has a thriving industrial and logistics industry, which supports the demand for conveying equipment. The presence of significant industrial and e-commerce firms in the region is likely to drive demand for conveying equipment. The rise of the logistics and warehousing industries has resulted from the growth of the e-commerce industry, which has increased online purchases. The rising demand for conveying equipment in various industries has resulted from the requirement for effective material handling and transportation systems.

During the projection period, the Asia Pacific region is expected to have the fastest revenue CAGR. The region is home to various growing economies, including China and India, which are rapidly industrializing and urbanizing. The expansion of these countries’ industrial and construction industries is likely to stimulate demand for conveying equipment. Furthermore, rising disposable incomes and changing consumer preferences have increased demand for consumer products, resulting in the expansion of the logistics and transportation businesses. The expansion of these businesses is likely to drive the region’s need for conveying equipment.

Over the projection period, the European market is expected to increase at a moderate rate. Several established industrial businesses, such as automotive, food and beverage, and pharmaceuticals, are located in the region and are important customers of conveying equipment. The region’s increased e-commerce activity is also likely to fuel demand for conveying equipment in the logistics and warehousing industries. Furthermore, the execution of rigorous rules for worker safety and environmental protection is projected to drive the region’s adoption of modern conveying equipment.

The global Conveying Equipment Market is highly competitive, with numerous large and medium-sized players dominating the market. These companies are constantly deploying various strategies, such as mergers & acquisitions, strategic agreements & contracts, and developing, testing, and introducing more effective products, to maintain their market position. The major players in the Conveying Equipment Market include:

| PARAMETERS | DETAILS |

| The market size value in 2022 | USD 27 Billion |

| CAGR (2022 - 2032) | 10% |

| The Revenue forecast in 2032 |

USD 63.66 Billion |

| Base year for estimation | 2022 |

| Historical data | 2020-2021 |

| Forecast period | 2022-2032 |

| Quantitative units |

|

| Report coverage | Revenue forecast, company ranking, competitive landscape, growth factors, and trends |

| Segments covered | By Product Type Outlook, End-Use Outlook, Regional Outlook |

| By Product Type Outlook |

|

| By End-Use Outlook |

|

| Regional scope | North America; Europe; Asia Pacific; Latin America ; Middle East & Africa |

| Country scope | U.S.; Canada; U.K.; Germany; France; BENELUX; China; India; Japan; South Korea; Brazil; Saudi Arabia; UAE; Turkey |

| Key companies profiled | Dematic Corporation, Siemens AG, Daifuku Co. Ltd, Fives Group, Emerson Electric Co, Intelligrated (Honeywell), Schaefer Systems International, Murata Machinery Ltd, Vanderlande Industries B.V, BEUMER Group GmbH & Co. KG |

| Customization scope | 10 hrs of free customization and expert consultation |

Facing issues finding the exact research to meet your business needs? Let us help you! One of our Research Executives will help you locate the research study that will answer your concerns. Speak to Analyst Request for Customization

Request a FREE Sample here to understand what more we have to offer over competition…

upto20% OFF

upto20% OFF

Want to curate the report according to your business needs

Report Description + Table of Content + Company Profiles