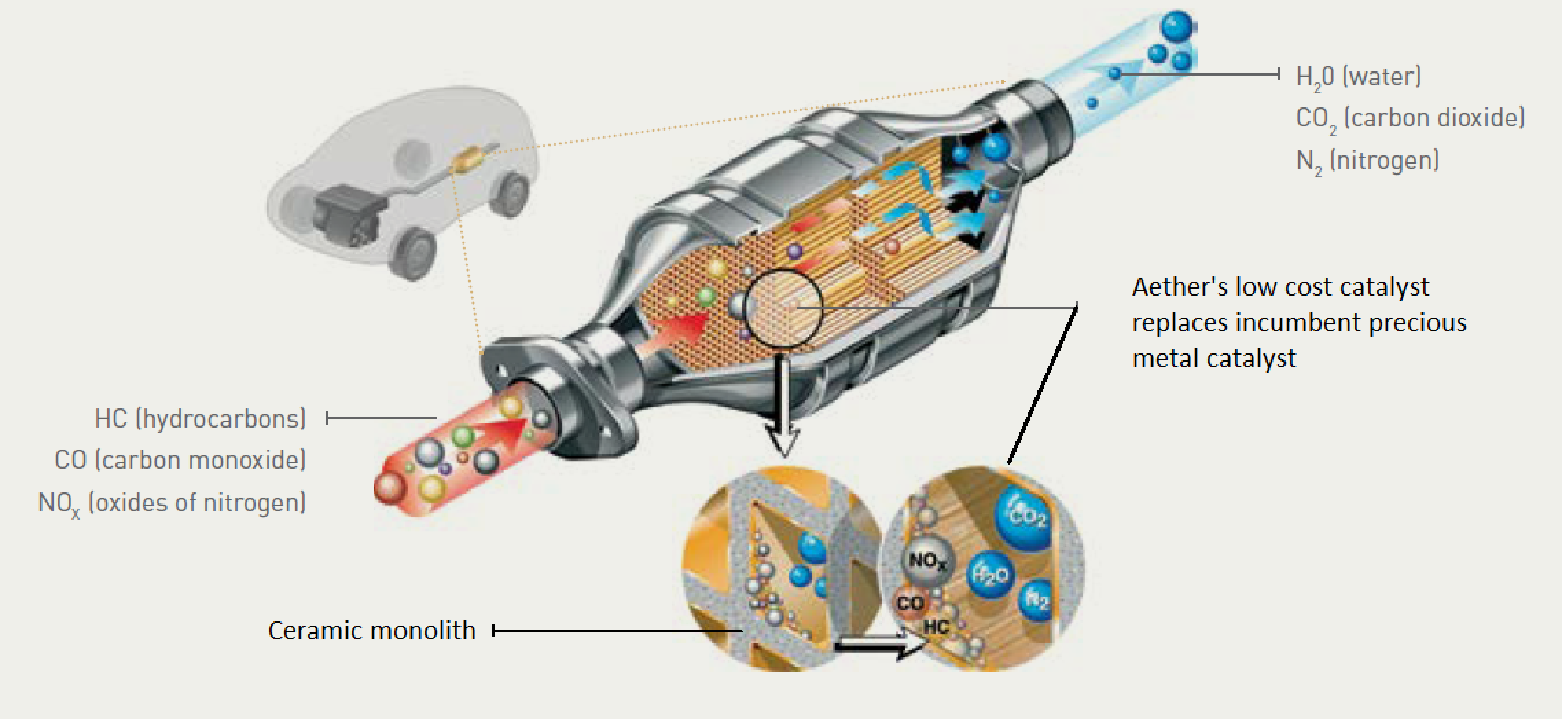

Aether Catalyst Solutions, Inc. has developed a low-cost, high-performance, three-way catalyst to replace the costly precious metals currently utilized in automotive catalytic converters. Our technology does not contain any platinum, palladium, or rhodium allowing for a 90% cost reduction over incumbent technology. Aether’s catalyst can be processed using simple wash-coating methods that are scalable to high volume and low costs. Utilizing industry standard testing and aging protocols, Aether has demonstrated high conversion rates of harmful exhaust gas after severe 900 C accelerated aging.

Key features of Aether catalyst technology are:

- High conversion of internal combustion exhaust gases to benign gases

- Demonstrated high level of aging robustness after harsh accelerated aging environments

- Order of magnitude cost reduction of catalytic converter catalyst

- Use of simple wash coating procedures allowing easy scaling to required sizes

- Applicable to all internal combustion engines including trucks, cars, motorcycle, small engines, etc.

FUNDING SUPPORT AGENCIES

FUNDED PROJECT PARTNERS

Aether Catalyst Solutions, Inc.

Unit 104, 8337 Eastlake Drive

Burnaby, B.C. V5A 4W2

(604)608-2886