Abstract

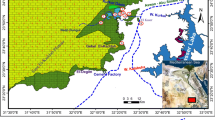

The Zoro pegmatite project in east-central Manitoba occurs 20 km east of the historic mining town of Snow Lake. A composite sample (Master Comp) was prepared from three pegmatite zones within Zoro Dyke “D1” including the North, Central, and South Zones for mineralogical analysis and heavy liquid separation (HLS). The mineralogical examination was conducted on a subsample crushed to ca. P80 of 600 μm to determine the overall mineral assemblage, liberation of spodumene, and assess the potential recovery of spodumene by flotation. XRD and QEMSCAN results show that the sample consists of spodumene (10.5%), quartz (29.3%), plagioclase (29.0%), K-feldspars (21.3%), micas (5.1%), tourmaline (2.9%), and Fe-Mn-phosphates (0.1%). Spodumene is well liberated (88%), but also forms complex particles (7%), and middlings with quartz (4%). Liberation of spodumene increases from 81 in the + 600 μm to 95% in the − 106 μm size fraction. Liberation of quartz, feldspars, and micas account for 89%, 94%, and 83%, respectively. Electron probe micro-analyses and LA-ICP-MS showed that the average Li concentration is 3.7% in spodumene, 2196 ppm in micas, 1001 ppm in tourmaline, and 115 ppm in K-feldspars. Thus, spodumene accounts for 96%, micas 2%, Fe-Mn phosphates 1%, and both K-feldspars and tourmaline for < 1% of the total Li in the sample. The mineralogical data indicate the potential to recover spodumene by flotation with minimal Li losses due to other than spodumene carriers. Heavy liquid separation was conducted on the Master Comp which was crushed to − 6.4 mm, while the − 600 μm fraction was removed from this test. The coarse fraction − 6.4 mm/+ 600 μm was subjected to HLS tests with eight heavy liquid-specific gravity cut-points (2.65 to 3.10 g/cm3). HLS indicates that it is possible to produce a high-grade lithium concentrate (close to 6% Li2O) after the rejection of iron silicates with magnetic separation.

Similar content being viewed by others

References

Jaskula BW (2014) 2014 minerals yearbook. Lithium. U.S.Geological Survey, U.S. Department of the Interior. http://minerals.usgs.gov/minerals/pubs/commodity/lithium/myb1-2014-lithi.pdf

Goonan TG (2012) Lithium use in batteries. U.S. Geological Survey, US Department of the Interior http://pubs.usgs.gov/circ/1371/pdf/circ1371_508.pdf

Bulatovic SM (2014) Beneficiation of lithium ores. In S. M. Bulatovic, Handbook of Flotation Reagents: Chemistry, Theory and Practice – Volume 3: Flotation of Industrial Minerals (pp. 41–56). Elsevier B.V

Ober JA (1994) 1994 minerals yearbook. Lithium. U.S. Geological Survey, U.S. Department of the Interior. http://minerals.usgs.gov/minerals/pubs/commodity/lithium/450494.pdf

Gasalla HJ, Aglietti EF, Lopez JMP, Pereira E (1987) Changes in physicochemical properties of α-spodumene by mechanochemical treatment. Mater Chem Phys 17:379–389

Gibson C, Aghamirian M, Grammatikopoulos T (2017) The beneficiation of lithium minerals from hard rock deposits. Min Eng 69:8

Heinrich EW, Salotti CA, Giardini AA (1978) Hydrogen- mineral reactions and their application to the removal of iron from spodumene. Energy 3:273–279

Clarke GM (2013) Lithium-ion batteries: raw material considerations. Chem Eng Prog 109:44–52

Grammatikopoulos TA, Pearse G, Gelcich S, Gunning C (2009) Quantitative characterization of spodumene ore by automated mineralogy from the Moblan rare metals pegmatite deposit, Quebec, Canada. In: Proceedings of the 48th Annual Conference of Metallurgists of CIM (MetSoc), pp. 65–76

Aylmore MG, Merigot K, Rickard WDA, Evans NJ, McDonald BJ, Catovic E, Spitalny P (2018) Assessment of a spodumene ore by advanced analytical and mass spectrometry techniques to determine its amenability to processing for the extraction of lithium. Miner Eng 119:137–148

Vizcarra TG, Harmer SL, Wightman EM, Johnson NW, Manlapig EV (2011) The influence of particle shape properties and associated surface chemistry on the flotation kinetics of chalcopyrite. Miner Eng 24:807–816

Jameson GJ (2012) The effect of surface liberation and particle size on flotation rate constants. Miner Eng 36–38:132–137

Xu L, Hu Y, Wu H, Tian J, Liu J, Gao Z, Wang L (2016) Purif Technol 169:33–42

Filippov L, Farrokhpay S, Lyo L, Filippova I (2019) Spodumene flotation mechanism. Minerals 9:372. https://doi.org/10.3390/min9060372

Beland C (2011) Geochemistry and geochronology of the Whabouchi pegmatite dykes as revealed through zircon. B.Sc., thesis, 99p

Sousa R, Ramos V, Guedes A, Botelho de Sousa A, Noronha F, Machado Leite M (2019) Flotation of lithium ores to obtain high-grade Li2O concentrates. Are there any mineralogical limitations? Int J Min Mater Metall Eng (IJMMME) 5:7–18

Thomas RJ, Bühmann D, Bullen WD, Scogings AJ, De Bruin D (1994) Unusual spodumene pegmatites from the Late Kibaran of southern Natal, South Africa. Ore Geol Rev 9:161–182

London D (1984) Experimental phase equilibria in the system LiAlSiO4-SiO2-H2O: a petrogenetic grid for lithium-rich pegmatites. Am Miner 69:995–1004

Selway JB, Breaks FW, Tindle AG (2005) A review of rare-element (Li-Cs-Ta) pegmatite exploration techniques for the Superior Province, Canada, and large worldwide tantalum deposits. Explor Min Geol 14(1–4):1–30

Tian J, Xu L, Wu H, Fang S, Deng W, Peng T, Sun W, Hu Y (2018) A novel approach for flotation recovery of spodumene, mica and feldspar from a lithium pegmatite ore. J Clean Prod 174:625–633

Deer WA, Howie RA, Zussman J (1978) Rock-forming minerals, 2A. Single-Chain Silicates, Longman

Zhu G, Cao Y, Wang Y, Wang X, Miller JD, Lu D, Zheng X (2020) Surface chemistry features of spodumene with isomorphous substitution. Miner Eng 146:106139. https://doi.org/10.1016/j.mineng.2019.106139

Salakjani NK, Singh P, Nikoloski AN (2019) Production of Lithium – a literature review part 1: pretreatment of Spodumene. Miner Process Extr Metall Rev 41:335–348. https://doi.org/10.1080/08827508.2019.1643343

Tian Q, Chen B, Chen Y, Ma I, Shi X (2011) Roasting and leaching behaviour of spodumene in sulfuric acid process. Chin J Rare Metals 35:118–123

Acknowledgments

We are grateful to Far Resources Ltd. for sampling and providing pegmatite samples from their D1 Zoro pegmatite. We are also thankful to SGS for the logistical support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Grammatikopoulos, T., Aghamirian, M., Fedikow, M. et al. Mineralogical Characterization and Preliminary Beneficiation of the Zoro Lithium Project, Manitoba, Canada. Mining, Metallurgy & Exploration 38, 329–346 (2021). https://doi.org/10.1007/s42461-020-00299-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-020-00299-2